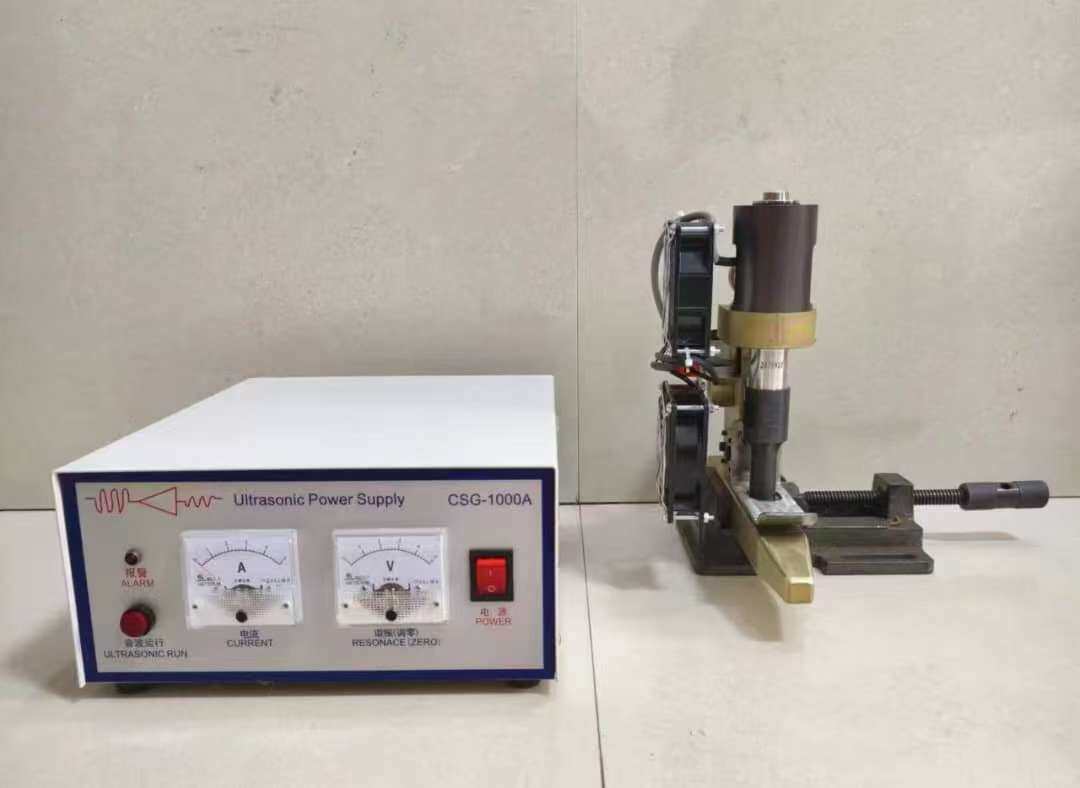

Advanced Ultrasonic Cutting Device for Looms With Touch Screen Interface and Real-Time Monitoring

As a leading innovator in industrial automation solutions, Xuzhou Guozi Intelligent Technology Co., Ltd. proudly presents our Advanced Ultrasonic Cutting Device engineered specifically for modern loom operations. Based in China's manufacturing hub of Xuzhou, Jiangsu, we've developed this cutting-edge system to address critical efficiency challenges in textile production. Our ultrasonic cutter delivers precision cutting without frayed edges while significantly reducing material waste – translating to measurable cost savings for your manufacturing facility.

Core Technical Advantages:

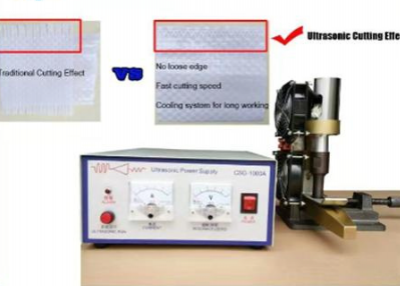

- Vibration-Free Cutting: Ultrasonic technology creates clean seals on synthetic fabrics without thermal damage

- Smart Operation: 10-inch industrial-grade touchscreen simplifies complex parameter adjustments

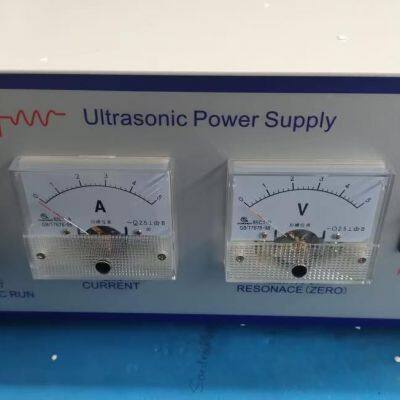

- Production Analytics: Real-time monitoring tracks blade performance and cutting accuracy

- Adaptive Integration: Modular design fits most industrial looms with minimal retrofitting

Technical Specifications:

| Parameter | Specification |

| Operating Frequency | 20kHz ± 0.5kHz |

| Cutting Speed Range | 5-25 meters/minute (adjustable) |

| Material Thickness Capacity | Up to 8mm layered textiles |

| Power Consumption | 1200W nominal |

| Interface Compatibility | RS485, Ethernet (optional) |

Operational Benefits for Manufacturers: Our ultrasonic cutting technology eliminates traditional blade changing downtime through continuous 500+ hour operation cycles. The non-contact method prevents fabric distortion during high-speed production, maintaining dimensional accuracy across batches. Integrated sensors automatically detect material density variations and adjust amplitude accordingly, ensuring consistent cut quality regardless of textile composition.

Maintenance & Reliability Features:

- Self-diagnostic system alerts for transducer maintenance

- Modular component design for quick serviceability

- Dust-resistant touchscreen rated for 24/7 operation

- Vibration-dampening mounts protect loom mechanics

Backed by Xuzhou Guozi Intelligent's decade of textile automation expertise, this ultrasonic cutting solution has been field-tested in over 50 weaving facilities across Asia. Our Jiangsu-based manufacturing center provides responsive technical support and maintains critical spare parts inventory for minimal operational disruption. Contact our engineering team today to discuss custom integration solutions – let us demonstrate how our precision cutting technology can reduce your fabric waste by up to 19% while increasing production line throughput.

Frequently Asked Questions:

Q: What maintenance does the ultrasonic blade require?

A: The titanium alloy blade requires periodic cleaning but no sharpening. Transducer maintenance is recommended every 800 operating hours.

Q: Can this cutter handle laminated or coated fabrics?

A: Yes, our amplitude control technology effectively cuts through polymer-coated textiles without delamination.

Q: Is operator training provided?

A: Comprehensive training modules are included with installation, covering both basic operation and advanced diagnostics.

Q: How does real-time monitoring improve production?

A: The system tracks blade efficiency, cutting consistency, and downtime causes for continuous process optimization.

Q: What safety features are incorporated?

A> Dual safety interlocks, emergency stop, and automatic shutdown upon detecting abnormal vibration patterns.

Q: Can it be integrated with existing PLC systems?

A: Communication protocols including Modbus TCP are available for seamless integration.

Send Inquiry to This Supplier

You May Also Like

-

Energy-Saving Ultrasonic Cutter for Textile Industry With Automatic Edge Detection and Sealing FunctionUS$ 950 - 1200MOQ: 2 Sets

-

Reliable Ultrasonic Cutting System for Textile Production Lines With Customizable Cutting ParametersUS$ 950 - 1200MOQ: 2 Sets

-

Ultrasonic Circular Loom Cutting Sealing Machine - High-Precision Fabric Cutting, Suitable for Woven/Knitted FabricsUS$ 950 - 1200MOQ: 2 Sets

-

Ultrasonic Cutter Advanced Ultrasonic Circular Loom Cutting Sealing Equipment for PP Woven IndustryUS$ 950 - 1200MOQ: 2 Sets

-

Ultrasonic Circular Loom Cutting Sealing Machine for PP Woven Bags With Auto Edge ControlUS$ 950 - 1200MOQ: 2 Sets

-

Ultrasonic Woven Fabric Sealing Cutter Ultrasonic Fabric Cutter for Circular Loom With Auto Edge Control SystemUS$ 950 - 1200MOQ: 2 Sets

-

Ultrasonic Cutter Welding Machine Precision Ultrasonic Circular Loom Cutting Sealing Machine for Woven FabricUS$ 950 - 1200MOQ: 2 Sets

-

High-Speed Ultrasonic Circular Loom Cutting Machine for PP Woven Fabric ProductionUS$ 950 - 1200MOQ: 2 Sets

-

Reliable Ultrasonic Circular Loom Finishing Machine With Auto Tension ControlUS$ 950 - 1100MOQ: 1 Set

-

Advanced Ultrasonic Technology for Seamless Cutting and Sealing of Woven BagsUS$ 950 - 1100MOQ: 1 Set