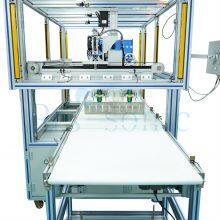

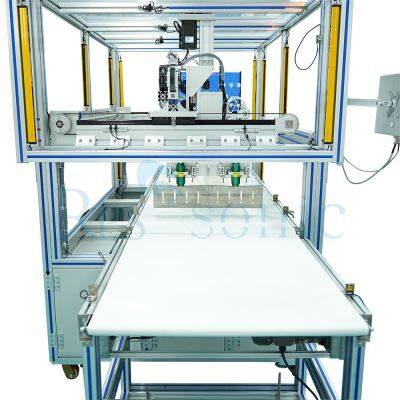

Factory Automatic Ultrasonic Food Cutting Machine Sonicator Chocolate Cutting With Conveyor Belt

Product description

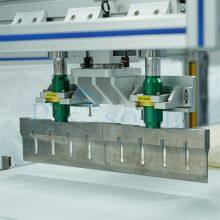

* Treat creamy jelly and other sticky food sticky knives, smooth and beautiful.

* Simple and fast product positioning, according to the needs of all-round cutting.

* The cutting products can be automatically positioned and cut according to the parameters entered in advance.

* Automatic use of conveyor belts for efficient food cutting, saving manpower.

* Respond to market consumers’ needs to maximize food hygiene and safety.

* During the slitting process, the job is fully automated without human intervention and increased productivity.

Also applied in rubber cutting , Rubber goods have high toughness, ultrasonic cutting knife can greatly reduceresistance and increase cutting speed.

♦ Bakery and snack foods,

♦ Candy and confectionery cheese/Fish/Prepared meat/Vegetable/Health Bars;

♦ Chocolates, sandwich and wrap cutting;

♦ Dry fruit;

♦ Poultry;

♦ Potted;

♦ Processed meat;

♦ Ground meat;

Send Inquiry to This Supplier

You May Also Like

-

Customized 20kHz Ultrasonic Cake Cutting Machine Ultrasonic Sandwich Cutter for Airline FoodUS$ 26000 - 28000MOQ: 1 Set

-

High Quality HDPE Welding Ultrasonic Welding Machine for HDPE Plastic Box Welder Electronic BoxUS$ 3200 - 3600MOQ: 1 Set

-

Automatic Desktype Ultrasonic Welding Machine Ultrasonic Seamless Welding Machine for Plastic and FabricUS$ 1800 - 2000MOQ: 1 Set

-

15khz High Quality Customized Horn Ultrasonic Welding Machine Plastic Welder With Digital GeneratorUS$ 3200 - 3500MOQ: 1 Set

-

High Frequency Ultrasonic Spraying Nozzle Slurry Spray Coating Machine Thin Film Coating AtomizerUS$ 4200 - 4500MOQ: 1 Set

-

High Frequency Ultrasonic Spray Nozzle Transducer Graphene Spray Coating Machine for Solar CellsUS$ 3600 - 3800MOQ: 1 Set

-

3000W Industry Ultrasonic Homogenizer Sonicator Liquid Mixer for Cosmetic Processing With HolderUS$ 2700 - 2900MOQ: 1 Set

-

Ultrasonic Homogenizer Sonicator Lab Liquid Mixer for Cosmetic Processing With Soundproof BoxUS$ 1900 - 2200MOQ: 1 Set

-

1500w Laboratory Grade Ultrasonic Homogenizer Perfume Processing Fan Cooling for Comestic EmulsificationUS$ 1900 - 2200MOQ: 1 Set

-

Ultrasonic Homogenizer Dispersion Emulsification Machine for Hemp Oil Mixing and Efficient EmulsifyingUS$ 2700 - 2900MOQ: 1 Set