Material

Other, Reinforced Rubber Composite

Usage

Other, River channel

Size

Customizable Dimensions Available

Control System

Automated PLC-Based Operation

Application

Water Resource Management

Certifications

QS9000, ISO9001, ISO9004

Energy Efficiency

High Savings Potential

Installation

Easy and Portable Setup

Brand

Hengshui Haogu

Transport Package

Container

Specification

Customized according to the drawings

Trademark

Haogu

Origin

Hengshui

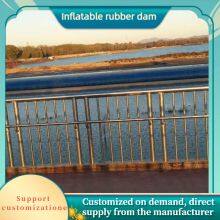

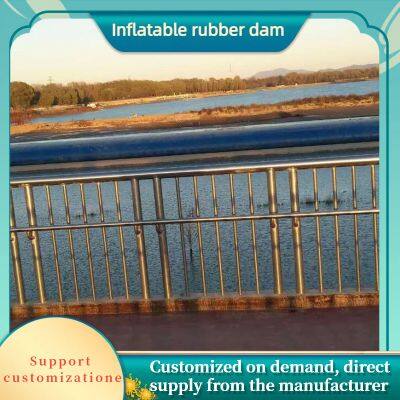

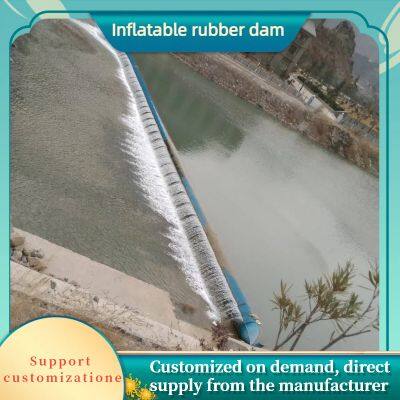

Custom Inflatable Rubber Dam – A Cost-Effective, High-Adaptability Solution for Water Conservancy ProjectsCore Value Summary

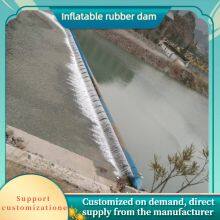

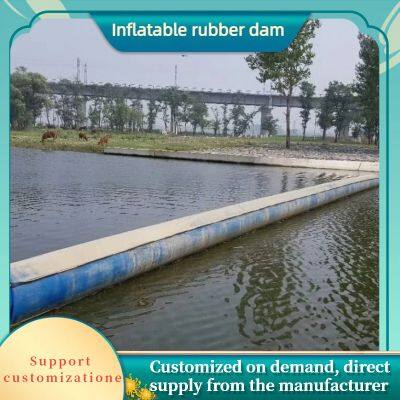

As a core product of flexible hydraulic structures, the inflatable rubber dam adjusts its height through water or air inflation to achieve water retention, storage, flood discharge, and other functions. Compared with traditional concrete dams and steel gates, it can save 30%-70% of project investment, shorten the construction period by 60%, and has a service life of 15-25 years. Widely applicable to low-head, large-span water conservancy projects, it is a cost-effective choice for flood control and disaster reduction, irrigation and water storage, ecological landscaping, and other projects.

I. Core Product Advantages (Addressing Procurement Pain Points)1. Cost-Effective, Significantly Reducing Overall Costs

Project investment is only 30%-50% of that of traditional sluices, saving more than 30% of steel, 50% of cement, and 60% of wood.

Operation and maintenance costs are as low as 20%-30% of traditional dams, with an annual operation and maintenance cost of only about 5,000 RMB, and the dam bag requires almost no frequent maintenance.

The single-span length can reach 100 meters without the need for intermediate piers, reducing infrastructure investment and saving 40% of land occupation under the same water storage capacity.

2. Rapid Construction, Shortening the Commissioning Cycle

The dam bag can be installed in only 3-15 days, and the overall project construction period is 60% shorter than that of traditional dams, realizing benefits in the same year of construction.

Modular production and roll transportation eliminate the need for large construction equipment, enabling easy deployment in remote areas or complex terrains.

3. Flexible Adaptability, Combining Ecology and Safety

The flexible dam body can resist earthquakes and wave impacts, adapt to uneven foundation settlement, achieve excellent water sealing effect, and have extremely low seepage.

It can be emptied and collapsed in non-flood seasons to form a natural waterway without blocking fish migration. After application in an ecological river channel, the migration frequency of native fish increased by 60%.

It buffers water flow impact, reduces sediment deposition, and the water transparency is 30% higher than that in areas with traditional water-retaining dams, while the algae growth is reduced by 25%.

4. Intelligent and Flexible, Convenient Operation and Maintenance

Precisely adjust the dam height through the inflation and drainage system (water pump/air compressor), supporting automatic control and remote monitoring with rapid water level adjustment response.

It can quickly collapse to discharge floods during the flood season without water-retaining obstacles, effectively reducing flood risks and adapting to mountain rivers prone to flash floods.

Colored dam bags are available (black, gray, green, blue, etc.) with smooth lines, suitable for municipal landscape projects and enhancing the value of the surrounding environment.

II. Core Product Types (Customizable to Meet Diverse Scenarios)1. Classified by Energy Filling Method

Water-Inflatable Rubber Dam: Lower cost and strong stability, suitable for fresh water scenarios such as inland rivers and irrigation channels.

Air-Inflatable Rubber Dam: Fast inflation and deflation speed, no frost heave risk in winter, suitable for low-temperature areas or projects requiring frequent adjustment.

Dual/Multiple-Chamber Rubber Dam: Uniform pressure distribution and high control precision, suitable for complex hydraulic conditions.

2. Classified by Structural Form

Bag-Type Rubber Dam: Most widely used, simple structure and cost-effective, suitable for most low-head projects.

Air Shield Rubber Dam: Strong impact resistance and longer service life, suitable for rivers with high flow velocity and many floating objects.

Sail/Spine-Type Rubber Dam: Flexible opening and closing, small floor space, suitable for narrow rivers or landscape projects.

Reinforced Rubber Dam: Built-in steel cable/steel mesh or polyester fabric skeleton, tensile strength increased by 30%, suitable for high-pressure scenarios.

III. Main Application Scenarios (Covering All Water Conservancy Project Needs)1. Flood Control and Disaster Reduction

River flood control and flash flood diversion. The rapid collapse design can avoid flood overtopping, suitable for flood control projects in medium and small river basins.

Urban waterlogging prevention, flexibly adjusting water levels to reserve flood storage capacity and reduce urban waterlogging risks.

2. Agricultural Irrigation and Water Storage

Irrigation area water storage and channel water distribution, dynamically adjusting water levels to meet irrigation needs, with a water storage utilization rate of 92% (14 percentage points higher than traditional water-retaining dams).

Reservoir spillway renovation, increasing storage capacity and power generation head, and improving the comprehensive benefits of water conservancy projects.

3. Municipal Landscape and Ecological Restoration

Urban river beautification and artificial lake water storage. Colored dam bags combined with water flow landscapes enhance urban livability.

Ecological river restoration, protecting aquatic organism habitats and reducing damage to coastal vegetation (the damage rate is only 1/5 of that of traditional dams).

4. Coastal Tide Blocking and Wave Prevention

Coastal tide gates and breakwaters, corrosion-resistant to seawater and anti-marine biofouling, with better performance than metal gates.

Groundwater recharge projects, intercepting seawater intrusion and protecting underground fresh water resources.

5. Construction and Special Projects

Construction Cofferdam (Movable Rubber Cofferdam), eliminating the need for soil extraction to build weirs, keeping the river clean, shortening the construction period and saving labor.

Upper and lower gates of ship locks, large-span design without affecting navigation, and flexible opening and closing.

IV. Core Technical Parameters (Accurately Matching Project Needs)

Material Characteristics Description

EPDM Rubber: UV-resistant, ozone-resistant, and aging-resistant, with a performance retention rate of >80% after aging, suitable for high-altitude, strong sunlight, and low-temperature areas.

Chloroprene Rubber (CR): Oil-resistant and wear-resistant, suitable for water conservancy scenarios with industrial wastewater and more oil pollution.

Integrally Formed Dam Bag: No secondary splicing, consistent tensile strength in all directions, no weak links, and significantly improved safety.

V. Customization Services and Cooperation Guarantees1. Full-Process Customization Support

On-Demand Design: Provide integrated customization solutions for dam type, size, and material according to project hydrological conditions, geological structure, and functional requirements.

Modular Production: Support customization of single-chamber, dual-chamber, and multi-chamber structures, and colored dam bags and special anchorage methods can be realized on demand.

2. One-Stop Engineering Services

Full-chain services from scheme design, product production, on-site installation to commissioning and acceptance, with a professional technical team providing on-site guidance.

Provide supporting solutions for inflation and drainage systems (water pumps/air compressors) and control systems (automatic inflation and drainage, remote monitoring), supporting intelligent upgrading.

3. Quality and After-Sales Guarantee

Products comply with "Technical Specifications for Rubber Dams" (SL 227) and international water conservancy engineering standards, and undergo multiple inspections such as air tightness, tensile strength, and seepage before leaving the factory.

Global Logistics and Distribution: Support sea, land, and air transportation, cooperate with customs clearance procedures to ensure on-time delivery.

After-Sales Support: Provide a 1-3 year warranty period, free repair and replacement of faulty parts within the warranty period, and lifelong technical consultation and maintenance guidance.

VI. Successful Case References

An Irrigation Project in Vietnam: Dam height 3.2m, single-span length 75m, water-inflatable rubber dam, solving the irrigation problem of 2,000 mu of farmland, with investment 40% lower than that of traditional sluices.

A Domestic Ecological River Restoration Project: Dam height 2.5m, total length 161m, EPDM colored dam bag, water transparency increased by 35%, and the migration frequency of native fish increased by 60%.

A Coastal Tide Blocking Project: Dam height 4.5m, single-span length 95m, seawater corrosion-resistant rubber dam, effectively intercepting tidal intrusion and protecting coastal farmland and groundwater environment.