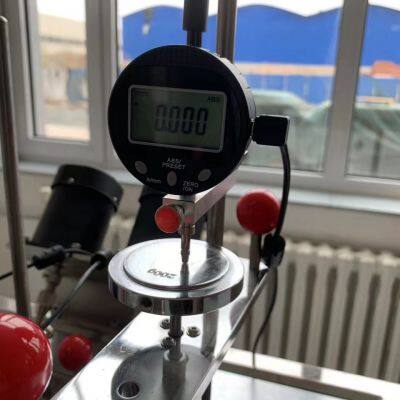

HST HDT / Vicat Softening Point Temperature Tester High Accuracy Lab Equipment for Plastic Rubber Pipe Material Testing

fiber reinforced composite materials, high strength thermosetting lamination materials and other non-metallic materials.

GB / T1633 "Determination of Vicat Softening Temperature (VST) of Thermoplastics"

GB / T1634 "Determination of Plastic Load Deformation Temperature Part 1: General Test Method"

GB / T8802 "Determination of softening temperature of plastic pipe fittings"

IS075-2013 "Determination of Plastic Load Deformation Temperature"

ASTM D 648 "Test Method for Thermal Deformation Temperature of Plastics"

ASTM D 1525 "Test Method for Vicat Softening Temperature of Plastics"

2.Technical Parameters:

Model | HST-HDTV3003S |

Structure | Table type |

Display | LCD display |

Sample Frame | Manual |

Temperature range | RT~300℃ |

Heating speed | 120℃/h [(12±1)℃/6min],50℃/h [(5±0.5)℃/6min] |

Max. temperature error | ±0.5℃ |

Maximum deformation measurement range | 1mm (Vicat test); 0.33 mm (thermal deformation) |

Heating medium | methyl silicone oil (below 200 centistokes) |

Maximum heating power | 3kw |

Working position | 3 (4 or 6 optional) |

Cooling method | natural cooling |

Three methods of load deformation temperature | Method A: 1.80MPa bending stress, Method B: 0.45MPa bending stress, Method C:8.00MPa bending stress |

Mass of load bar and pallet | 68g+1g |

Power supply | AC220V, 10A, 50Hz |

Equipment standard configuration:

Name | Qty | Remark |

Mainframe | 1 Set | Table Type,LCD display |

Test Stand | 3 Sets | The test frame span is divided into two types: 64mm and 100mm, you can choose any test method. |

Motion detector | 3 Sets | Measurement deformation error ±0.005mm |

Temperature Sensor | 1 Suit | The measurement error imported from the United States is ±0.5℃ |

Thermal deformation indenter | 3 Sets | The arc radius is R3 |

Vicat test indenter | 3 Sets | Cross-sectional area is 1mm |

Instrument features

The temperature signal sensed by the temperature sensor is input to the amplifier, and is input to the temperature control meter through the analog switch and A/D conversion. The corresponding heating parameters are given by running the PID program (in the instrument) to control the heating time of the heater, thereby achieving the temperature control goal. The purpose is to enable the test to be carried out safely and reliably, thereby ensuring the safety and reliability of the test. The biggest feature is that it is easy to operate

50N-5KN Single Column Universal Testing Machine | Electronic Universal Testing Machine with 10kN Pneumatic Grips | Electronic Universal Testing Machine with Hydraulic grips |

Electronic Universal Testing Machine with Temperature Chamber | 50kN -1000kN Hydraulic Dynamic Static Fatigue Testing Machine | 100kN -2000kN Servo Hydraulic Universal Testing Machine |

Send Inquiry to This Supplier

You May Also Like

-

HST-561 Large-capacity Dichloromethane Impregnation Testing Machine Methylene Chloride TesterUS$ 3500 - 4200MOQ: 1 Set

-

HST ASTM D1525 ASTM D648 Temperature Deflection Vicat Softening Test ApparatusUS$ 12596.22 - 13995.80MOQ: 1 Set

-

HST Vicat Softening Point Heat Distortion Testing Machine, Automatic Needle Vicats ApparatusUS$ 12596.22 - 13995.80MOQ: 1 Set

-

ISO 811 Fabric Hydrostatic Head Pressure TesterUS$ 1999 - 4500MOQ: 1 Set

-

XNR-400A Manual MFR Plastic Melt Flow Rate Test MachineUS$ 6997.90 - 8397.48MOQ: 1 Set

-

Plastic Material Impact Specimen V Notch Broaching MachineNegotiableMOQ: 1

-

HQZ-IID Full Automatic Sample V Notch Cutting Cutter Machine for PlasticNegotiableMOQ: 1

-

HQZ-IID Electronic Plastic Sample Notching MachineNegotiableMOQ: 1

-

QK-20 Plastic Izod Chary Impact Manual Sample Notch MachineNegotiableMOQ: 1

-

Plasti Impact Specimen V Notch Broaching MachineNegotiableMOQ: 1