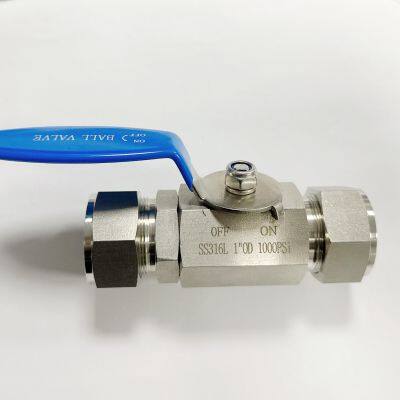

Precision Double Ferrule Needle Valve With Fine Flow Control for Laboratory Equipment

Engineered for critical fluid handling applications, the Precision Double Ferrule Needle Valve delivers unparalleled flow regulation in laboratory and analytical systems. This high-integrity valve features a dual-ferrule compression seal that eliminates leaks under extreme pressures while maintaining precise control over minute fluid volumes. Designed specifically for chromatography, chemical injection, and research instrumentation, its micro-adjustment capability enables operators to achieve flow rates with ±1% repeatability – essential for reproducible experimental results.

The robust stainless steel construction withstands corrosive media and maintains structural integrity at pressures up to 6000 psi, outperforming conventional needle valves in both reliability and longevity. With zero dead volume design and bubble-tight shutoff, this valve prevents sample contamination and system pressure drops, making it ideal for:

- HPLC & GC analytical systems

- High-purity gas distribution

- Precision dosing equipment

- Laboratory reactor feed lines

Technical specifications include:

| Feature | Specification |

| Body Material | 316 Stainless Steel |

| Connection Types | NPT, BSPP, VCR (optional) |

| Pressure Rating | 6000 psi @ 38°C |

| Flow Coefficient (Cv) | 0.08 - 0.15 |

| Stem Travel | 8mm with 40 turns |

The double-ferrule grip mechanism provides uniform sealing force around the tubing without distortion, preventing cold flow and ensuring consistent performance through thousands of actuation cycles. Unlike single-ferrule designs, this configuration maintains seal integrity during thermal cycling and vibration – critical for sensitive instrumentation. Operators benefit from tool-free maintenance and finger-tight repairability, reducing downtime in critical processes.

Additional engineering advantages include:

- Rotary stem design prevents gland packing wear

- Integrated thrust bearing for smooth operation

- Non-rotating tip preserves seat integrity

- Passivated surfaces meet SEMI F20 standards

For laboratories requiring ultra-clean processes, the QBNV series is available with electropolished interiors (Ra ≤ 10 µin) and certified helium leak testing to 1x10-9 atm·cc/sec. Custom configurations such as metering handles, position indicators, or specialized stem tips can be provided to match specific application requirements.

Upgrade your fluid control systems with valves that deliver measurable performance advantages: reduced calibration frequency, elimination of unintended flow variations, and extended service intervals. Contact our engineering team today for technical consultation or to request validation data sheets demonstrating leakage rates and cycle life testing results.

Frequently Asked Questions:

-

Q: Can this valve handle aggressive chemicals?

A: The 316L stainless steel construction provides excellent resistance to acids, alkalis, and solvents. For highly corrosive media, Hastelloy versions are available. -

Q: What tubing sizes are compatible?

A: Standard configurations support 1/8" to 1/4" OD tubing. Metric sizes and custom tube grips can be supplied upon request. -

Q: How many cycles can the valve endure?

A: Laboratory testing shows consistent performance beyond 25,000 full-stroke cycles with minimal leakage deviation. -

Q: Is calibration required after installation?

A: The precision-ground stem and seat maintain calibration through normal use. Periodic verification is recommended for critical applications. -

Q: Can I integrate this with automated systems?

A: Yes, optional stepper motor adapters and position feedback sensors enable automated flow control integration. -

Q: What maintenance is required?

A: The maintenance-free design requires only periodic external cleaning. Seal replacement kits are available for extended service life.

Send Inquiry to This Supplier

You May Also Like

-

Precision Double Ferrule Instrument Valve, 316L Stainless Steel, for Analytical and Measurement SystemsNegotiableMOQ: 100 Sets

-

Premium Stainless Steel Double Ferrule Valve for High-Purity Systems, 1/4" to 1" Size RangeNegotiableMOQ: 100 Sets

-

High-Pressure Double Ferrule Tube Fitting Valve, 6000 PSI, Stainless Steel 316L MaterialNegotiableMOQ: 100 Sets

-

Compact Stainless Steel Double Ferrule Isolation Valve, 1/4" to 1/2" NPT, for Lab EquipmentNegotiableMOQ: 100 Sets

-

Full Bore Instrumentation Ball Valve With Double Ferrules and Fire Safe DesignNegotiableMOQ: 500 Units

-

High Flow Double Ferrule Ball Valve for Analytical Instrumentation and SamplingNegotiableMOQ: 500 Units

-

Double Ferrule Ball Valve With Locking Lever for Gas and Liquid SystemsNegotiableMOQ: 500 Units

-

Corrosion Resistant 316 SS Ball Valve With Double Ferrule Connections 6000 PSINegotiableMOQ: 500 Units

-

Zero Leakage Instrumentation Ball Valve With Double Ferrules and Full Port DesignNegotiableMOQ: 500 Units

-

High-Pressure Double Ferrule Ball Valve With PTFE Seal and Bi-Directional SealingNegotiableMOQ: 10 Pieces