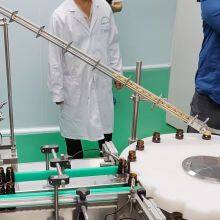

Glass & Plastic Bottle Piston-Type Automatic Juice Beverage Filling and Capping Integrated Machine | Full-Automatic Filling Production Line

Send Inquiry to This Supplier

You May Also Like

-

Laboratory DSI Steam Sterilization Beverage and Fruit Juice Pasteurization Machine Fresh Milk Yogurt Sterilized Filling EquipmentUS$ 35000 - 50000MOQ: 1 Piece

-

Automated Factory Bubble Tea Popping Pearl Production Line, Juice Bobo Making Machine, Pearl Popping MachineUS$ 10000MOQ: 1 Piece

-

Fermented Milk, Cheese, Dairy Product Production Line, Whey Wine, Milk, Yogurt, Dairy Product Processing MachineryUS$ 50000MOQ: 1 Piece

-

Automatic Sterilization Device for Soybean PasteTomato Sauce Preparation MachineEmulsified Sauce Production SystemUS$ 10000 - 50000MOQ: 1 Piece

-

Industrial Automatic Yogurt Production Line, Cheese Manufacturing Machine, Milk Pasteurization, Filling, Sealing Machine, Dairy Products EquipmentNegotiableMOQ: 1 Piece

-

Automated Factory Supplier: Juice Bursting Ball Production Line, Cold Crystal Ball Manufacturing MachineNegotiableMOQ: 1 Piece

-

Automatic Dairy Product Processing Machine, High-temperature Sterilization and Filling Production Line, Pasteurization Equipment for MilkNegotiableMOQ: 1 Piece

-

Customized DSI Direct Steam Jet Sterilization Machine 20L Laboratory Batch Sterilizer and Sterile Filling Machine Suitable for Fresh Milk, YogurtNegotiableMOQ: 1 Piece

-

Industrial Custom Milk Pasteurization Machine, High Temperature Tube-Type Sterilization MachineNegotiableMOQ: 1 Piece

-

Automatic Ultra-high Pressure Nanometer HomogenizerNegotiableMOQ: 1 Piece