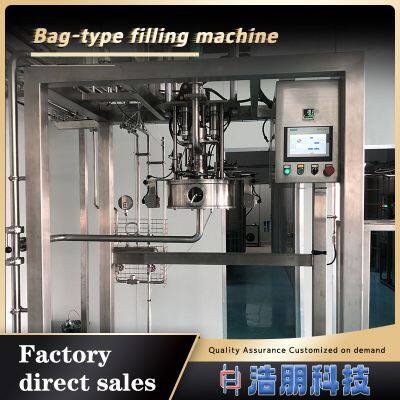

* The small aseptic filling machine for large packaging is suitable for aseptic filling of red dates, tomatoes, apples, oranges, roxburgh rose, sea buckthorn, wolfberries and other fruit and vegetable juices, jams or other concentrated products, dairy products and other viscous or non viscous fluids. Aseptic filling machine incluses single head filling machine and double head filling machine, with a filling range of 2L-220L. Using flowmeter control, filling accuracy is within 5 ‰.

* The equipment adopts steam to ensure a sterile environment, and all moving parts of the machine are provided with steam barrier for aseptic treatment.

* The filling machine adopts a one click start mode, and all intermediate links of action are confirmed by the sensors, absolutely eliminating equipment misoperation,

* The temperature of the sterile filling chamber is>95 ℃, and the equipment is allowed to fill to ensure product sterility. The filling room can only be filled after sterilization for more than 30 minutes. All filling weights and temperature settings can be modified on the touch screen;

* The rack is welded with 80x80x3mm 06Cr19Ni10 stainless steel square tubes;