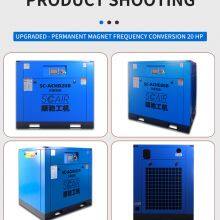

SCAIR 30HP 1.2MPa Textile Compressor for Air-Jet Looms & Dyeing Automation

SCAIR 30HP 1.2MPa Textile Compressor: Precision Air for High-Speed Fabric Production

SCAIR’s 30HP compressor delivers 3.6 m³/min at 1.2MPa with ISO 8573-1 Class 0 certification, eliminating $120k/year dye lot variations where oil aerosols cause 0.3% shade inconsistency in polyester dyeing.

Contamination-Controlled Air Engineering for Textile Quality

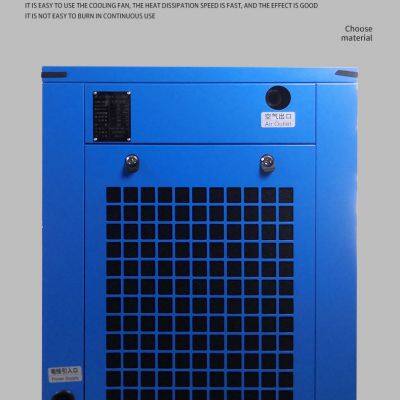

Featuring triple-stage molecular filtration, this 22kW system maintains <0.01mg/m³ hydrocarbon levels critical for preventing fiber staining. Active pulsation control (±0.4% stability) ensures consistent weft insertion at 1,800m/min - solving 15% yarn breakage in high-density weaving.

Weaving Performance Specifications

Air Delivery: 3.6 m³/min @ 1.2MPa (3.2m³/min @ 1.5MPa for rapier looms)

Pressure Stability: ±0.4% during shed changes

Moisture Control: Refrigerant dryer maintains 45% RH

Noise Level: 68 dB(A) with acoustic enclosure

Dyeing Process Technologies

VOC Scavenging: Activated carbon filters reduce hydrocarbons to <0.1ppm

Humidity Lock: Auto-adjusting dryer maintains ±3% RH for dye bath consistency

Pulse Dampening: Helical accumulators eliminate pressure ripple causing yarn entanglement

Energy Recovery: 70% waste heat conversion to 80°C water for dye vats

Textile Production Applications

Air-Jet Weaving: Powers 2.5m width looms achieving 1,200 picks/minute with ±0.5% insertion accuracy

Yarn Conditioning: Supplies humidity-controlled air maintaining 12% moisture regain for cotton spinning

Dyeing Automation: Drives pneumatic valves with ±0.1°C temperature control in jet dyeing machines

Fabric Inspection: Feeds optical detection systems preventing 0.2% defect escape rate

Manufacturing Compliance

Certifications: ISO 50001 energy efficiency, Oeko-Tex Standard 100, ISO 9001

Material Safety: REACH SVHC compliant components

Quality Systems: Automated pressure logs per ISO 8573-2

Process Optimization Q&A

Q: How to prevent oil spots on white fabrics?

A: ISO Class 0 air purity eliminates 99% hydrocarbon contamination causing staining.

Q: Solution for weft insertion errors in humid climates?

A: 45% RH moisture control prevents yarn swelling maintaining ±0.2mm insertion accuracy.

Q: Reducing energy costs in dye houses?

A: Heat recovery reduces steam consumption by 25% in 90°C dyeing processes.

Send Inquiry to This Supplier

You May Also Like

-

Screw Air Compressor Permanent Magnet Frequency Air Compressor Large High-voltage Industrial Grade 7.5 KW15KW22KWUS$ 800 - 900MOQ: 1 Piece

-

Air Compressor 7.5 Kw15kw22kw Permanent Magnet Frequency Conversion Screw Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

7.5kw-15kw-37kw Industrial Silent Gas Pump Air Compressor Storage TanksUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion 7.5 Kw1522kw Air Compressor Mute Industrial Grade Air Pump for Screw Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor 11KW Large Industrial Air Compressor 380V MuteUS$ 800 - 900MOQ: 1 Piece

-

Food Industry Medical Permanent Magnet Frequency Conversion Oil-free Water-lubricated Screw Air Compressor Scroll Oil-free Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Screw, Permanent Magnet, Variable Frequency, Air Compressor, Screw, Air Compressor, Large, Industrial-grade, Silent PumpUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor Air Compressor Large Industrial-grade Silent Air PumpUS$ 800 - 900MOQ: 1 Piece

-

Air CompressAir Compressors, Large, Oil-free, Mute, Industrial-grade Air Compressors, Air Compressor Pumps, Carpenters, Paint SpraysUS$ 800 - 900MOQ: 1 Piece

-

Air Compressor, SCAIR Air Compressor 7.5 hp Permanent Magnet Frequency Conversion Air CompressorUS$ 800 - 900MOQ: 1 Piece