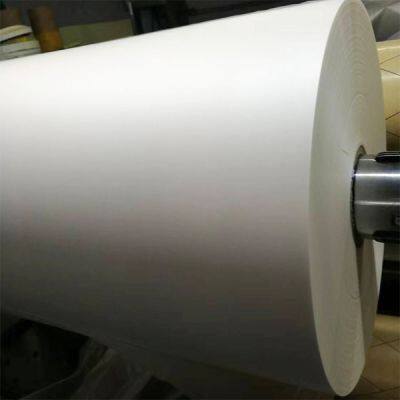

17 Mic Gloss BOPP Thermal Lamination Film for Hot Lamination by Laminating Machine

Product Description

BOPP thermal laminating film glossy

Laminating film is the composite film with substrate and the thermal adhesive layer coated together to laminate with the desired material (such as print).

Laminating film thickness measured in MIL or MICRON ,affects cost, rigidity, optical clarity and UV inhibition.

Typically laminates are used on both front or back of image for protection, strength and to add rigidity.

The user should also bear in mind that images have a tendency to curl towards the thicker side ,

if laminates are not balanced in thickness.

| Item | bopp thermal laminating film glossy | |||||

| Thickness (Micron) | Total | 15 micron | 17 micron | 20 micron | 25 micron | 30 micron |

| Base | 10 micron | 12 micron | 12 micron | 15 micron | 18 micron | |

| EVA | 5 micron | 5 micron | 8 micron | 10 micron | 12 micron | |

| Customized from 15-30micron,with tolerance ±1um | ||||||

| Width(mm) | 160-1900mm (customized ±3um) | |||||

| Length(m) | 150-300Meters for 1'' core; 2000-4000Meters for 3'' core | |||||

| Paper Core | 25.4mm(1'')/76mm(3'') | |||||

| Corona Side | single side; double sides | |||||

| Connector | ≤ 1 | |||||

| Tensile density | MD:2.4*106dyne/cm CD:5.3*106dyne/cm | |||||

| Laminating on paper by manual | ||||||

| Hot Melt Point | 80℃/185 ℉-110℃/230 ℉ | |||||

| Pressure | 10-18 mPa | |||||

| Speed | 10-60M/min | |||||

Yield

1005 Gloss | 1205 Gloss | 1208 Gloss | 1510 Gloss | 1812 Gloss | 1205 Matte | 1208 Matte | 1510 Matte | 1812 Matte | Unit |

| 77 | 64.5 | 54.6 | 43.7 | 36.4 | 67.2 | 56.4 | 45.1 | 37.6 | m2/kg |

| 13 | 15.5 | 18.3 | 22.9 | 27.5 | 14.9 | 17.7 | 22.2 | 26.6 | g/m2 |

Features- BOPP thermal laminating film glossy

1) Environmental friendly: non-hazardous to health and safe to use as no toxic gases or volatile content is emitted. Safe in laminating process as no solvent based adhesive is used.

2) High function: compared with other solvent lamination, our film is better in clarity and bonding. It’s preventing lamination from being pressed, bubbled and shredding off easily. Matt thermal lamination film is good for spot UV and hot stamping.

3) Easy handling: it is easy to operate once the required temperature is met and no special technique is required.

4) Efficient and energy-saving: Production is reduced substantially as there is no film wastage, mixture of adhesive solvent, and no UV heating lamp is required.

5) Adaptable to different kinds of machines: This is recommended to be used in dry laminator. Small adjustments need to be made to the machine if the film is used in wet laminator.

6) Strong ability of absorbing power: unlike solvent adhesive, our film is suitable for lamination even with powdery paper

Applications

Covers

Books, magazines, periodicals, brochure, etc.

Packaging

Crates or boxes for liquor, food and beverage, medicine, cosmetics and other daily consumer products and bags etc.

Trade-shows

Advertisement products, Photos, documents, billboards, certificate,etc.

1. Adjust roller pressure and temperature according to different types of paper and ink.

2. When using the film for the first time or changing the usual size, a small trial volume before starting massive lamination is proposed.

3. Normal process temperature is 90C-105C (203F - 221F), roller pressure and temperature vary from different types of paper, ink and machines.

4. Make sure the ink is dry before laminating. It will delaminate when the paper contains too much moisture or powder.

5. Make sure to put the material in place with low temperature and dry.

6. The following situation will affect the final quality of the film during lamination.

a. Using metal ink

b. Ink containing too much wax, dried oil, adhesive, silicon additive and so on.

c. Much too thick ink

d. Ink completely not dried yet.

e. Much too humid paper sheet.

f. Too much powder on the surface

Process Parameter

1. Equipment for laminating film: dry and wet film lamination machines

2. Compound Temperature:

normal: 85-110℃ special: 100-110℃

3. Compound Pressure: 8-18MPa

4. Compound Speed: 8-50m/min

Packaging - bopp thermal laminating film glossy

Export Worthy for long distance shipment

*One Roll per carton- 3'' core; 10rolls per carton - 1'' core,rolls are well packed by air bubble bag

*Tens of rolls on a pallet,cartons are well wrapped by clear stretch film on a pallet.

*10 to 12 pallets loaded into 1*20ft container (appro. 13MTs)

*Or 20 to 22 pallets loaded into a 40ft container (appro. 25MTs)

----Free samples,freight collect

*By SHEET, eye check,unable to test by machine,lowest freight charge.

*By ROLL,machine test,higher freight charge.

normal size: 500-mm width 100M length 1/3inch core(up to your machine)

*Tips for cost saving:

Thanks for your trust to request a sample for check,here are few tips for you to save cost.

if permits,choose 1''core not 3'' core.

Deliver via our logistic and prepay the freight to us.

----Quick response

*24 hours Trade Manager online.

----Delivery on time

Zhengzhou Pengsheng Packaging Material Co.,Ltd,founded in 1992,which is the earliest manufacturer of producing BOPP Thermal Lamination Film.Located in Zhengzhou,Henan.We commit ourselves to the production,R&D and marketing of different types of BOPP Thermal Lamination Film with advanced automatic production lines,strict quality control systerm,we has winned trusts and supports from the clients all over the world.

We are certified with the ISO9001 and European Union SGS CMA and MSDS test.Our product quality has met international standard,which met the requirements of international environmental friendly.we have exported to nearly thirty countries,such as Germany,South Africa,Middle East,Africa.etc.

Until now, Pengsheng has more than 200 employees including 20 researchers. We always adhere to the culture of “Enthusiasm,Innovation,Harmony and Win-win”and the management ideas of “Technology First,Quality First,Service First and Reputation First”. Taking honest,pragmatism,endeavor and innovation-oriented,We will cooperate and strive for brilliant future with all staffs.

Much more inforamtion , please feel free let me know , we would like to your kindly inquiry !

Send Inquiry to This Supplier

You May Also Like

-

Transparent BOPP Holographic Thermal Laminating Film With Kinds of DesignsUS$ 2150MOQ: 500 Kilograms

-

Metallic Gold PET Laminatinion Film for Cake CarboardUS$ 2790MOQ: 1000 Kilograms

-

Colored PET Metalized Thermal Lamination Film With Kinds of Gold ColorsUS$ 2790MOQ: 1000 Kilograms

-

PET/BOPP Metalzied Thermal Lamination Film Silver and Gold Color Chemical Treatment for UV PrintingUS$ 2790MOQ: 1000 Kilograms

-

Finger-free BOPP Soft Touch Thermal Lamination Film for Luxury PackagingUS$ 3150MOQ: 100 Kilograms

-

High Clarity Plastic Coating Rolls BOPP Laminating Roll Film for Board LaminateUS$ 1750MOQ: 2000 Kilograms

-

FDA Qualified Transparent Film Laminating Plastic for Paper LaminateUS$ 1750MOQ: 2000 Kilograms

-

EVA Pre-Coated Hot Lamination Roll for High Speed Laminator MachinesUS$ 1750MOQ: 2000 Kilograms

-

Gold PET Metalized Thermal Lamination Film With Kinds of Gold ColorsUS$ 2790MOQ: 1000 Kilograms

-

Amazing Hologram Pattern Laminating Holographic Film, Customized Logo Pattern AvailableUS$ 2150MOQ: 500 Kilograms