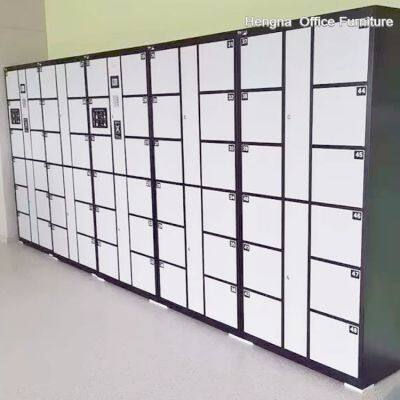

Heavy Duty Electronic Lockers High Frequency Encryption Anti-Magnetic 48 Door Factory Industrial Workplace Security Storage

The Heavy Duty Electronic Lockers with High Frequency Encryption and Anti-Magnetic Technology represent the pinnacle of industrial security storage solutions, specifically engineered for demanding factory and workplace environments. This robust 48-door electronic locker system combines military-grade security features with industrial-strength construction to provide unparalleled protection for valuable assets, sensitive equipment, and confidential materials in high-risk industrial settings. The integration of high-frequency encryption technology and anti-magnetic shielding ensures that stored items remain secure from both physical theft and electronic interference, making this system an essential investment for manufacturing facilities, research laboratories, and industrial workplaces where security and reliability are paramount. Designed to withstand the harsh conditions typical of industrial environments, these lockers offer a comprehensive security solution that addresses the unique challenges faced by modern industrial operations.

High Frequency Encryption Technology: Implements advanced 13.56MHz encrypted communication protocols that prevent unauthorized access through electronic hacking or signal interception, ensuring that only authorized personnel can operate the lockers.

Anti-Magnetic Shielding: Features specialized magnetic shielding materials that protect sensitive electronic equipment and data storage devices from electromagnetic interference, making these lockers ideal for industrial environments with high electromagnetic fields.

Heavy Duty Construction: Manufactured from reinforced steel with thickness ranging from 2mm to 5mm in critical areas, providing exceptional resistance to physical force, drilling, and cutting attempts commonly encountered in industrial security breaches.

48-Door Configuration: Optimally designed with 48 individual compartments that maximize storage capacity while maintaining a compact footprint suitable for factory floor installation and high-traffic industrial areas.

Multi-Factor Authentication: Supports various authentication methods including biometric fingerprint recognition, RFID cards, PIN codes, and combination access, providing flexible security options for different industrial applications and user privilege levels.

Industrial-Grade Electronics: Utilizes components specifically designed for harsh industrial environments, with operating temperature ranges from -20°C to 60°C and resistance to dust, moisture, and vibration typical of manufacturing settings.

Advanced Audit Trail System: Records all access attempts with precise timestamps, user identification, and biometric verification, creating comprehensive security logs that comply with industrial safety standards and regulatory requirements.

Emergency Override Systems: Incorporates mechanical override mechanisms and backup power systems that ensure access during power failures or emergency situations, maintaining operational continuity in critical industrial environments.

| Feature | Specification |

|---|---|

| Door Configuration | 48 compartments (16 small, 24 medium, 8 large) |

| Construction Material | Reinforced steel (2-5mm thickness) with anti-corrosion coating |

| Encryption Technology | 13.56MHz high-frequency encryption with AES-256 bit |

| Magnetic Protection | 90dB electromagnetic shielding effectiveness |

| Access Methods | Biometric, RFID, PIN code, mechanical key override |

| Power Supply | AC 100-240V with battery backup (72 hours) |

| Dimensions | H 2400mm × W 3200mm × D 600mm |

| Weight | Approximately 580 kg |

| Operating Temperature | -20°C to 60°C (-4°F to 140°F) |

| Protection Rating | IP65 (dust and water resistance) |

| Network Connectivity | Ethernet, RS485, optional Wi-Fi |

| Security Certifications | CE, FCC, ISO 9001, UL 1037 |

| Response Time | <1 second for authentication |

| Warranty Period | 5 years comprehensive coverage |

The combination of high-frequency encryption and anti-magnetic technology creates a security barrier that exceeds conventional electronic locker systems. The encrypted communication protocols prevent sophisticated electronic attacks that might compromise lesser systems, while the anti-magnetic shielding protects sensitive industrial equipment from electromagnetic interference that could cause data corruption or equipment malfunction. This dual protection approach ensures that stored items remain secure from both physical and electronic threats, providing peace of mind for industrial managers responsible for protecting valuable assets and sensitive materials. The heavy-duty steel construction with reinforced door frames and tamper-resistant hinges provides physical security that withstands determined attempts at forced entry, making these lockers suitable for high-security industrial applications.

Operational Efficiency in Industrial SettingsIndustrial environments demand equipment that can operate reliably under harsh conditions without frequent maintenance or downtime. These heavy-duty electronic lockers are engineered specifically for such environments, with components that resist dust, moisture, vibration, and temperature extremes common in manufacturing facilities. The rapid authentication response time of less than one second minimizes worker downtime during shift changes, while the intuitive user interface reduces training requirements for new employees. The system’s ability to handle multiple authentication methods accommodates diverse workforce requirements, from cleanroom environments requiring biometric access to general factory areas where RFID cards may be more practical. This flexibility ensures that the locker system integrates seamlessly into existing industrial workflows without disrupting productivity.

Compliance and Regulatory SupportIndustrial facilities must comply with numerous safety and security regulations, and these electronic lockers are designed to support such compliance efforts. The comprehensive audit trail system maintains detailed records of all access attempts, supporting regulatory reporting requirements and internal security protocols. The system’s ability to implement hierarchical access controls helps enforce safety procedures by ensuring that only properly trained and authorized personnel can access certain equipment or materials. The emergency override systems and backup power capabilities ensure compliance with safety regulations that require access to critical equipment during emergency situations. For facilities handling sensitive materials or operating in regulated industries, these lockers provide the security infrastructure necessary to maintain compliance while protecting valuable assets.

Long-Term Investment ValueWhile the initial investment in heavy-duty electronic lockers may be higher than conventional storage solutions, the long-term value proposition is compelling. The robust construction and industrial-grade components ensure reliable operation for many years, even in harsh environments, reducing replacement costs and minimizing downtime. The advanced security features reduce losses from theft or unauthorized access, providing measurable financial benefits over time. The system’s scalability and flexibility allow it to adapt to changing industrial requirements without requiring complete replacement, protecting the investment for years to come. Additionally, the enhanced security and professional appearance of these lockers can improve workplace morale and demonstrate management’s commitment to employee security and asset protection.

Installation and IntegrationIndustrial Site PreparationProper installation in industrial environments requires careful planning and preparation to ensure optimal performance and longevity. The installation area must provide adequate structural support for the substantial weight of the 48-door system, typically requiring reinforced flooring or concrete foundations. Electrical supply must meet industrial standards with proper grounding and surge protection to safeguard the sensitive electronic components. Network infrastructure should be installed with industrial-grade cabling and protection against electromagnetic interference common in factory environments. The installation location should provide adequate clearance for door operation and maintenance access while considering workflow patterns and security requirements specific to the industrial facility.

Integration with Industrial SystemsThe heavy-duty electronic locker system seamlessly integrates with existing industrial security infrastructure, including access control systems, surveillance networks, and building management systems. The system’s communication protocols support integration with industrial automation systems, enabling automated access based on production schedules or employee shift patterns. For facilities with existing RFID or biometric systems, the lockers can be configured to use the same credentials, creating a unified security ecosystem across the entire industrial operation. The audit trail data can be integrated with industrial safety management systems, providing comprehensive security monitoring that supports both operational efficiency and regulatory compliance.

Professional Installation ProcessCertified industrial installation specialists handle the complete deployment process, beginning with comprehensive site assessment and ending with thorough testing and employee training. The installation process typically takes 4-5 days for the 48-door system, including structural preparation, electrical and network connections, system configuration, and integration with existing security infrastructure. Technicians conduct extensive testing of all security features, including encryption protocols, anti-magnetic shielding effectiveness, and emergency override systems. The installation process includes detailed training for security personnel and facility managers, ensuring they can effectively utilize all system features and respond appropriately to any security incidents or system alerts.

Applications and Use CasesManufacturing Facility SecurityIn manufacturing environments, these heavy-duty lockers provide secure storage for valuable tools, specialized equipment, and sensitive production materials. The anti-magnetic protection is particularly valuable for facilities storing precision instruments or electronic components that could be damaged by electromagnetic interference. The high-frequency encryption ensures that only authorized production personnel can access specific tools or materials, supporting inventory control and preventing unauthorized use of expensive equipment. The system’s ability to implement time-based access controls supports shift-based operations while maintaining security during shift changes.

Research and Development LaboratoriesResearch facilities require exceptional security for sensitive prototypes, intellectual property, and specialized equipment. The combination of physical security and electronic protection makes these lockers ideal for storing research materials that must be protected from both theft and electromagnetic interference. The comprehensive audit trail supports laboratory security protocols by maintaining detailed records of who accessed specific materials and when, which is crucial for research integrity and regulatory compliance. The anti-magnetic shielding protects sensitive research instruments and data storage devices from electromagnetic fields that could compromise experimental results or corrupt valuable research data.

Industrial Tool Crib ManagementTool cribs in industrial facilities benefit from the advanced security and tracking capabilities of these electronic lockers. The system can be configured to track tool usage, implement check-out/check-in procedures, and generate reports on tool utilization and maintenance requirements. The heavy-duty construction protects valuable tools from damage and theft, while the multiple authentication methods ensure that only properly trained personnel can access specialized equipment. The system’s integration capabilities with inventory management software enable real-time tracking of tool availability and automatic reordering when supplies run low.

Industrial facilities often maintain sensitive documents, including proprietary designs, safety procedures, and regulatory compliance records. These heavy-duty lockers provide the security necessary to protect such documents from unauthorized access while the anti-magnetic shielding protects electronic storage media from data corruption. The system’s audit trail capabilities support document control procedures by maintaining records of document access and retrieval. For facilities handling classified or proprietary information, the high-frequency encryption ensures that even sophisticated attempts at electronic interception are unsuccessful.

Maintenance and SupportIndustrial Maintenance ProtocolMaintaining optimal performance in industrial environments requires a comprehensive maintenance program tailored to harsh operating conditions. Daily visual inspections should check for physical damage, tampering attempts, or environmental contamination. Weekly cleaning of biometric sensors and card readers maintains reliable operation in dusty or dirty industrial environments. Monthly testing of backup systems and encryption protocols ensures continued security protection. Quarterly professional maintenance visits include comprehensive inspection of mechanical components, verification of anti-magnetic shielding effectiveness, and calibration of electronic systems. Annual service contracts provide priority support and extended warranty coverage for critical industrial applications.

Technical Support ServicesIndustrial facilities require specialized technical support that understands the unique challenges of manufacturing environments. Comprehensive support services include 24/7 remote assistance with security specialists familiar with industrial applications, on-site service response within 24 hours for critical issues, and regular security updates that address emerging threats and vulnerabilities. The support team includes experts in industrial security protocols, regulatory compliance requirements, and integration with industrial automation systems. Training programs for facility maintenance staff ensure that routine maintenance and troubleshooting can be handled internally, minimizing downtime and reducing reliance on external service providers.

System Upgrades and Future-ProofingThe modular architecture of these heavy-duty electronic lockers allows for system upgrades and enhancements as security technology evolves and industrial requirements change. Software updates can introduce new encryption algorithms, improve biometric recognition accuracy, and enhance integration capabilities with industrial systems. Hardware modules can be upgraded to support new authentication technologies or expanded to accommodate changing storage requirements. The system’s scalable design ensures that it can grow with the industrial facility’s needs, providing long-term value and protecting the investment for many years of reliable service.

The Heavy Duty Electronic Lockers with High Frequency Encryption and Anti-Magnetic Technology represent the ultimate security storage solution for demanding industrial environments. By combining military-grade encryption technology with robust physical construction and specialized anti-magnetic protection, this 48-door system addresses the comprehensive security needs of modern manufacturing facilities, research laboratories, and industrial workplaces. The system’s ability to withstand harsh environmental conditions while providing advanced security features makes it an essential investment for industrial operations where asset protection and regulatory compliance are critical. As industrial security challenges continue to evolve and technology advances, this heavy-duty locker system stands ready to provide the protection and reliability necessary for industrial operations to thrive in an increasingly complex security landscape. The combination of advanced technology, robust construction, and comprehensive support services ensures that these lockers will continue to meet the demanding security requirements of industrial environments for many years to come.

Send Inquiry to This Supplier

You May Also Like

-

Manufacturer of Infrared Barcode - Enabled Storing CabinetsNegotiableMOQ: 1 Piece

-

Barcode Storage Lockers for Shopping Malls and Supermarkets PriceNegotiableMOQ: 1 Piece

-

Suitable fo Mall & Supermarket Electronic Locker-24 Door Keypad Code Bag Storage LockerNegotiableMOQ: 1 Piece

-

Commercial Infrared Barcode Electronic Lockers |Gym Electronic 12 - Door Secure Digital LockerUS$ 300 - 550MOQ: 15 Pieces

-

Customized Oem Small Lockers Wholesale Factory|24-door Electronic Locker for SchoolUS$ 300 - 550MOQ: 15 Pieces

-

36-door Automatic Bag-Storage Cupboard QST-036 Electronic Lockers SuppliersUS$ 300 - 550MOQ: 15 Pieces

-

Face Recognition Smart Locker Price | 50-door Public Places Cell Phone Smart LockerUS$ 203 - 750MOQ: 15 Pieces

-

School Gym Lockers Price |Parcel Delivery Storage Locker 12-door FactoryUS$ 203 - 750MOQ: 15 Pieces

-

Smart Phone Charging Locker 40-door|Fingerprint Lockers Intelligent Parcel Delivery CabinetUS$ 203 - 750MOQ: 15 Pieces

-

QST-24 Barcode Controlled Storage Cabinet With Voice Guidance |Self-service Storage Locker for GymUS$ 300 - 880MOQ: 15 Pieces