Durable Steel Workbench With Anti-Static Top and Power Outlets for Electronics Assembly

In today’s electronics manufacturing landscape, where precision, safety, and efficiency are paramount concerns, the durable steel workbench with anti-static top and power outlets has become an indispensable component of modern assembly lines and electronics manufacturing facilities. This comprehensive solution addresses the unique challenges of electronics assembly, where sensitive components require special handling, and where power accessibility directly impacts workflow efficiency. The combination of robust steel construction, ESD-safe surfaces, and integrated power solutions creates a workstation that not only protects valuable electronic components but also enhances productivity and safety in demanding manufacturing environments.

The foundation of this durable steel workbench begins with its robust construction, engineered to withstand the demanding conditions of electronics manufacturing environments:

Frame Construction: Heavy-duty steel frame with reinforced joints and welded connections

Weight Capacity: Supports up to 500kg distributed load for heavy electronic equipment

Stability Testing: Engineered to remain stable under dynamic loading conditions

Longevity: Designed for 15-20 years of continuous industrial use

The work surface incorporates advanced materials for electronics assembly:

| Surface Feature | Specification | Application |

|------------------|-------------|

Anti-Static Laminate: ESD-safe surface protecting sensitive components | Safe for electronics assembly |

Chemical Resistance: Resists flux, solvents, and industrial chemicals | Easy cleaning and maintenance |

Impact Resistance: Withstands drops, impacts, and abrasion | Durable construction for heavy use |

Heat Resistance: Tolerates heat from soldering and testing processes | Suitable for electronics manufacturing |

The anti-static top provides comprehensive protection for electronic components:

Surface Resistivity: Surface resistivity less than 10^9 ohms per square

Grounding Capability: Grounding system dissipates static charge buildup

Static Dissipation: Rapid dissipation of static electricity

Compliance Standards: Meets IEC 61331 standards for ESD protection

The anti-static features provide significant safety advantages:

Component Protection: Prevents electrostatic discharge damage to sensitive electronics

Employee Safety: Reduces risk of electrostatic discharge injuries

Product Quality: Maintains electronic component integrity during assembly

Compliance Assurance: Meets industry standards for ESD protection

The integrated power outlets enhance workstation functionality:

Outlet Configuration: Multiple outlets positioned for convenient access

Power Distribution: Strategic placement for various equipment needs

Safety Features: Ground fault circuit interrupters for electrical safety

Surge Protection: Overcurrent protection for connected equipment

The electrical system incorporates comprehensive safety features:

| Safety Feature | Specification | Safety Benefit |

|---|

Ground Fault Circuit Interrupters: Prevents electrical shock hazards | Enhanced user safety |

| Circuit Breakers: Protects equipment from electrical damage | Equipment protection |Surge Protection: Ground fault circuit interrupters | Enhanced electrical safety |

| UL Listed Components: All components meet safety standards | Regulatory compliance |

This dustrial workbench system supports various electronics manufacturing processes:

Assembly Lines: Organized tools and components for efficient assembly operations

Quality Control: Organized inspection tools and measuring equipment

Testing Stations: Secure storage for testing equipment and instruments

Repair Operations: Organized repair tools and maintenance supplies

The integrated system delivers measurable improvements:

Tool Retrieval Time: 60-70% reduction in time spent searching for tools

Workflow Efficiency: Smooth transitions between different assembly stages

Error Reduction: Organized storage prevents component selection errors

Productivity Gains: 25-35% improvement in assembly throughput

The steel workbench design prioritizes user comfort and safety:

Adjustable Height: Height range from 750mm to 1000mm for different user heights

Ergonomic Design: Reduces physical strain during prolonged assembly operations

User Comfort: Features designed for extended work sessions

Safety Features: Rounded edges and smooth surfaces prevent injuries

Modern designs incorporate user-friendly elements:

Comfortable Height: Optimal working height for various users

Easy Access: Tools positioned within comfortable reaching distance

Visual Organization: Clear organization reduces cognitive load

Physical Comfort: Features reducing fatigue and physical stress

The total cost of ownership includes:

Initial Purchase: Workbench and power system acquisition

Maintenance Costs: Regular maintenance and upkeep

Replacement Costs: Extended lifespan reduces replacement frequency

Productivity Gains: Improved efficiency and reduced downtime

Safety Benefits: Reduced accidents and improved workplace safety

Durable steel workbench systems offer extensive customization:

Height Adjustment: Adjustable height for different user requirements

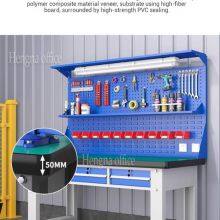

Pegboard Configuration: Customizable hook patterns and layouts

Drawer Configuration: Various drawer combinations for different needs

Color Options: Multiple color choices for visual organization

Power Options: Various outlet configurations and power management systems

Design features that support future needs:

Modular Expansion: Additional components can be added as needs change

Technology Integration: Compatible with digital monitoring systems

Customization Options: Tailored configurations for specific applications

Upgrade Path: Components can be upgraded without complete replacement

Proper installation ensures optimal performance:

Site Assessment: Location assessment and floor preparation

Electrical Safety: Ground fault circuit interrupter installation

Assembly: Professional assembly and positioning

Testing: Verification of all features and functionality

Training: User education on proper use and maintenance

Power system setup requires careful attention:

Circuit Planning: Separate circuits for different equipment types

Load Calculation: Ensure circuits support connected equipment

Grounding: Proper grounding for all electrical components

Safety Verification: Testing of all safety features and compliance

Regular maintenance ensures optimal performance:

| Maintenance Task | Frequency | Time Required | Tools Required |

|------------------|-------------|--------------|

| Surface Cleaning: Daily | 10 minutes | Mild detergent, soft cloth |

| Electrical Testing: Monthly | 15 minutes | Voltage tester, multimeter |

Grounding Verification: Quarterly | 30 minutes | Ground resistance tester |

| Component Check: Semi-annually | 1 hour | Visual inspection checklist |

| Deep Cleaning: Semi-annually | 2 hours | Specialized cleaning products |

Extend workbench lifespan through proper care:

Regular Cleaning: Prevents dirt buildup and corrosion

Lubrication: Reduces wear on moving parts

Prompt Repairs: Address issues before they become major problems

Protective Measures: Use of mats and covers to prevent damage

Durable steel workbench systems incorporate comprehensive safety features:

Anti-Static Protection: ESD-safe materials and grounding systems

Electrical Safety: Ground fault circuit interrupters and safety outlets

Structural Stability: Anti-tip design prevents cabinet tipping

Secure Storage: Lockable drawers protect valuable components

Ensure compliance with relevant standards:

OSHA Standards: Meets or exceeds workplace safety requirements

Electrical Codes: Complies with National Electrical Code requirements

ESD Standards: Meets IEC 61331 standards for ESD protection

Industrial Safety: Designed for industrial manufacturing environments

The durable steel workbench with anti-static top and power outlets represents the ultimate workstation solution for modern electronics manufacturing environments. By combining robust construction, ESD-safe surfaces, and integrated power solutions, this system creates a comprehensive workstation that protects valuable electronic components while enhancing productivity and safety.

The integration of anti-static protection with power accessibility creates a safe, efficient environment for electronics assembly operations. The combination of heavy-duty construction, advanced features, and thoughtful design creates a workspace that supports manufacturing excellence and employee safety.

For electronics manufacturers seeking to optimize their assembly operations and protect their valuable electronic components, this integrated workbench system offers the perfect combination of durability, safety, and functionality. The combination of immediate benefits and long-term value makes this system an essential investment for modern electronics manufacturing operations seeking to achieve operational excellence and competitive advantages.

As electronics manufacturing continues to evolve and technology advances, those who invest in advanced workbench systems with anti-static protection and power integration will be best positioned to achieve manufacturing excellence, product quality, and customer satisfaction. The future of electronics manufacturing belongs to those who understand that protecting components during assembly and handling directly impacts product quality and business success.

Send Inquiry to This Supplier

You May Also Like

-

Heavy Load Capacity Workbench With Green Surface and 8 Drawers for Precision Engineering SupplierUS$ 99 - 209MOQ: 2 Combos

-

Industrial Workbench With Hanging Boards and Lockable Drawers for Maintenance Operations ManufacturerUS$ 99 - 209MOQ: 2 Combos

-

Hengna Heavy Duty Workbench With ESD Top and Storage Options for Laboratory UseUS$ 99 - 209MOQ: 2 Combos

-

Hengna Industrial Production Work Table|Heavy Duty Solid Wood Workbench for WorkshopUS$ 300 - 800MOQ: 2 Cases

-

Commercial Workbench Supplier |Multi Metal Work Bench With Drawers OMDUS$ 300 - 800MOQ: 2 Cases

-

Multi Metal Work Benches Electrical Workshop Workbench|US$ 300 - 800MOQ: 2 Cases

-

Heavy Duty Workbench for Garage & Workshop | Industrial Strength WorkbenchesUS$ 200 - 600MOQ: 5 Sets

-

Modular Workbench With Pegboard for Tool OrganizationUS$ 600 - 1200MOQ: 5 Combos

-

Heavy-Duty Automotive Workbench - 1000 Lbs Capacity Steel Workbench for Car Repair ShopsUS$ 200 - 600MOQ: 5 Sets

-

Industrial Steel Workbench for Manufacturing - Heavy-Duty Assembly Workstation With StorageUS$ 200 - 600MOQ: 5 Sets