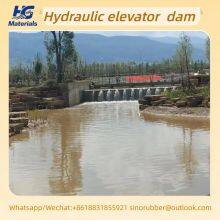

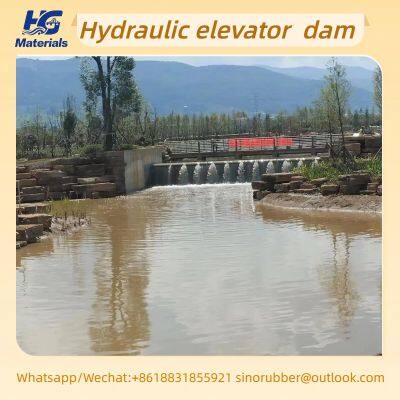

Hydraulic Elevator Dam With Automatic Control System for River Management

The Hydraulic Elevator Dam with Automatic Control System represents a revolutionary solution for modern river management and flood control. Engineered by Hengshui Haogu Engineering Materials Co., Ltd., this advanced water control system combines robust construction with intelligent automation to deliver unmatched performance in water regulation projects. With its precision engineering and reliable operation, this dam system offers municipalities and environmental agencies a comprehensive approach to watershed management that adapts to changing hydrological conditions.

Our hydraulic elevator dam features real-time monitoring capabilities and automated response protocols that significantly reduce human intervention requirements. The system's modular design allows for customizable configurations to suit various river widths and flow conditions, making it suitable for diverse geographical applications from urban waterways to agricultural irrigation channels.

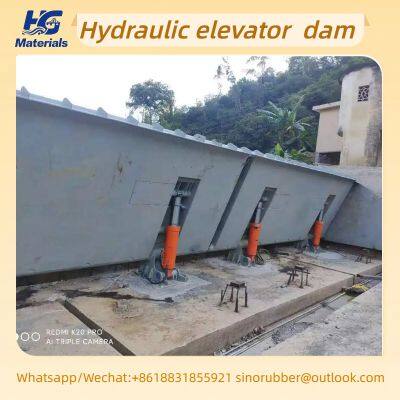

Built to withstand extreme environmental conditions, this dam system employs military-grade corrosion protection with multiple coating layers that ensure decades of maintenance-free service. The automatic control system integrates with existing hydrological networks through standard communication protocols, providing seamless data sharing with regional water management authorities.

| Parameter | Specification | Performance Range |

|---|---|---|

| Gate Height Adjustment | Vertical travel distance | 0.5-8 meters |

| Flow Rate Management | Maximum controlled flow | Up to 500 m³/s |

| Response Time | Full height adjustment | 2-5 minutes |

| Operating Temperature | Ambient range | -30°C to +65°C |

Technical Advantages:

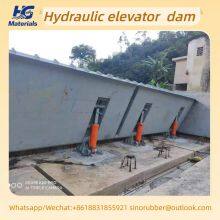

- Dual redundant hydraulic power units ensure continuous operation even during maintenance cycles

- Integrated debris management system prevents obstruction buildup that compromises performance

- Fail-safe emergency lowering mechanism activates during power outages or system anomalies

- Real-time data logging with cloud storage integration for regulatory compliance documentation

The control system architecture employs triple-redundant sensors for water level monitoring, creating a fault-tolerant measurement system that maintains accuracy even with component failure. Our proprietary algorithm processes hydrological data to predict flow patterns, enabling proactive adjustments that minimize downstream impact during sudden weather events.

Installation flexibility stands as a hallmark of our hydraulic elevator dam system. The modular construction allows implementation in phases across wide river spans without complete waterway closure. Foundation requirements are minimized through balanced pressure design, reducing civil engineering costs by up to 40% compared to traditional dam structures.

With global deployment experience across five continents, our solutions have been proven in diverse environments from tropical river basins to alpine watersheds. The system's standardized interfaces simplify integration with existing flood warning networks and SCADA systems, creating a unified water management platform.

Operational Benefits:

- 25% reduction in flood damage costs through precise water level maintenance

- 60% decrease in operational staffing requirements compared to manual gate systems

- 15-year design lifespan with extendable service cycles through component replacement

- Comprehensive remote diagnostics reduce on-site maintenance visits by 70%

As climate patterns become increasingly unpredictable, our Hydraulic Elevator Dam provides water management authorities with adaptive infrastructure that responds dynamically to changing conditions. The system's predictive capabilities and automated response protocols create a resilient water control solution that protects communities while optimizing water resource utilization.

Contact our engineering team today to schedule a virtual demonstration of how this advanced river management system can address your specific watershed challenges. With our ISO-certified manufacturing processes and global support network, we deliver turnkey solutions that meet international technical standards while accommodating local environmental requirements.

Frequently Asked Questions

Q: What is the maximum river width this system can accommodate?

A: Our modular design allows installation across rivers up to 200 meters wide through sequential gate placement. Each gate segment spans 5-10 meters depending on hydraulic requirements.

Q: How does the system perform during power outages?

A: Integrated backup power maintains critical functions for 72 hours. The fail-safe mechanism automatically lowers gates to predetermined safe positions if power isn't restored.

Q: What maintenance is required for the hydraulic system?

A: Automated lubrication and filtration systems minimize manual maintenance. Remote diagnostics alert technicians when component inspection or fluid changes are needed.

Q: Can the system integrate with existing flood warning networks?

A: Yes, standard communication protocols (MODBUS, DNP3) enable seamless data exchange with most hydrological monitoring systems.

Q: What environmental impact assessments are required before installation?

A: Our engineering team provides comprehensive support for environmental compliance documentation, including fish migration studies and sediment transport analysis.

Send Inquiry to This Supplier

You May Also Like

-

High-Performance Hydraulic Elevator Dam for Long Service Life and Low Maintenance CostsUS$ 260 - 300MOQ: 10 Square Meters

-

Rubber-Material Hydraulic Elevator Dam for Superior Durability in Construction Industry ApplicationsUS$ 260 - 300MOQ: 10 Square Meters

-

Heavy-Duty Hydraulic Elevator Dam With Adjustable Size for Industrial Elevator SystemsUS$ 260 - 300MOQ: 10 Square Meters

-

Compact Hydraulic Elevator Dam With 100mm Stroke Size for Space-Saving Elevator InstallationsUS$ 260 - 300MOQ: 10 Square Meters

-

Hydraulic Elevator Dam for Smooth Ride and Safety in High-Rise Building ElevatorsUS$ 260 - 300MOQ: 10 Square Meters

-

Ecological Airbag Support DamUS$ 260 - 300MOQ: 10 Square Meters

-

Pneumatic Shield Steel GateUS$ 260 - 300MOQ: 10 Square Meters

-

Pneumatic Shield GateUS$ 260 - 300MOQ: 10 Square Meters

-

Air-cushion Steel Gate DamUS$ 260 - 300MOQ: 10 Square Meters

-

Air-supported DamUS$ 260 - 300MOQ: 10 Square Meters