Inconel 625 Capillary Tubes: Chinese Quality Manufacturing Unlocks Unlimited Creative Application Possibilities.

Stainless steel, an epitome of versatility, is meticulously categorized based on its processing methods: pressure working steel and cutting steel. Delving deeper, it unveils five distinctive structural types: austenitic, austenite-ferritic, ferritic, martensitic, and precipitation hardening. Each type carries its unique set of attributes and applications, showcasing the adaptability of stainless steel across various industries.

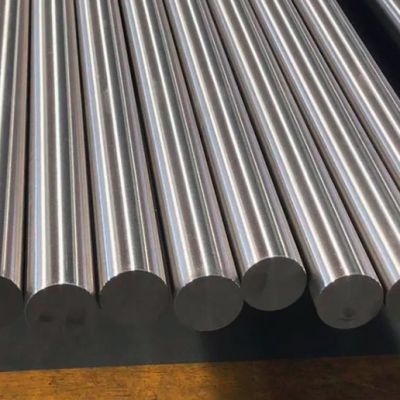

Stainless steel rods are the cornerstones of numerous industries and are renowned for their extensive applicability. They find their place in the crafting of hardware kitchenware, the robust shipbuilding sector, the intricate petrochemical industry, and the precise machinery and medical fields. They are indispensable in the production of food, the harnessing of electricity, the provision of energy, and the realms of construction and decoration. Their pivotal role extends to the nuclear power sector, the vast reaches of aerospace, the strategic military applications, and beyond! These rods also serve crucial roles in seawater equipment and various chemical processes, including dyeing, papermaking, and the production of oxalic acid and fertilizers. Additionally, they are vital in the food industry and coastal facilities and are used for manufacturing ropes, CD rods, bolts, and nuts.

Quality management is at the heart of our operations, with stringent adherence to the ISO9001:2000 quality management system certification and possession of all necessary production licenses. This commitment to quality ensures that every product meets the highest standards of excellence and reliability.

Remarks: Embrace the versatility and bespoke nature of our offerings with the ability to customize non-standard stainless steel rods across a variety of materials and specifications. Tailor your needs with precision engineering.

Stainless Steel Rod Material, Application Range, and Introduction to Quality Management

Our stainless steel offerings include a diverse array of materials: 201, 202, 301, 304, 303, 316, 316L, 304L, 321, 2520, 1Cr13, 2Cr13, 3Cr13, dual-phase steel, antibacterial steel, among others. Specifications are typically indicated by diameter, such as '50', denoting a round steel bar with a 50 mm diameter. We offer round steel in three forms: hot rolled, forged, and cold drawn, with sizes for hot rolled round bars ranging from 5.5 to 250 mm. This extensive variety ensures a perfect match for your specific application needs.

Application Range: Our stainless steel rods are quintessential for a wide spectrum of industries such as petroleum, electronics, chemical industries, medicine, textiles, food processing, machinery, construction, nuclear power, aerospace, and military sectors. Each application benefits from the superior durability and functionality that our stainless steel rods bring.

Quality Management: Our unwavering dedication to quality is demonstrated through our ISO9001:2000 quality management system certification and the possession of essential production licenses, ensuring that our products consistently reach superior standards of quality and performance.

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤1.00 | 5.5~7.5 | ≤0.060 | ≤0.03 | 3.50~5.50 | 16.00~18.00 | |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 4.00~6.00 | 17.00~19.00 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 6.00~8.00 | 16.00~18.00 | |

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~10.00 | 17.00~19.00 | |

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~10.50 | 18.00~20.00 | - |

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 9.00~13.00 | 18.00~20.00 | - |

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 19.00~22.00 | 24.00~26.00 | - |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 |

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 9.00~13.00 | 17.00~19.00 | - |

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | ≤0.60 | 16.00~18.00 | - |

| 430A | ≤0.06 | ≤0.50 | ≤0.50 | ≤0.030 | ≤0.05 | ≤0.25 | 14.00~17.00 |

Stainless Steel, renowned for its impeccable corrosion resistance and enduring stainless qualities, is defined by its composition: at least 10.5% chromium and no more than 1.2% carbon. This unique formulation endows it with remarkable durability and resilience, making it an ideal choice for demanding environments and applications.

Stainless steel rods, with their expansive application potential, are indispensable across many sectors. From hardware kitchenware to shipbuilding, petrochemicals, machinery, medicine, food production, electricity, energy, construction, and decoration, to the rigorous demands of nuclear power, aerospace, and military uses, they are integral. These rods are essential in seawater equipment and various industrial processes involving chemicals, dyes, and papermaking, as well as in the production of oxalic acid and fertilizers. They are also a mainstay in the food industry and coastal facility construction, frequently used in the manufacture of ropes, CD rods, bolts, and nuts.

Main Features

1. Weldability

Different product uses have distinct demands for welding performance. While items like tableware often bypass welding needs, a world of functionality depends on seamless joints. Consider second-class tableware, thermos cups, steel pipes, water heaters, and water dispensers; these essentials rely on the superior welding prowess of raw materials to ensure durability and longevity.

2. Corrosion resistance

Stainless steel products shine with their outstanding corrosion resistance, a pivotal trait for Class I and II tableware, kitchenware, water heaters, and dispensers. International standards often involve rigorous tests, like immersing products in a heated NACL solution. Post-boiling, the solution is drained, the product is washed, dried, and its weight loss is measured to evaluate corrosion levels. Take note: when polished, iron content from abrasive materials can induce surface rust spots during testing.

3. Polishing performance

In the modern manufacturing landscape, the gleam of stainless steel is crucial, with many products subjected to polishing. Few exceptions, such as internal components of water heaters and dispensers, may forgo this step. Superior polishing performance of raw materials is essential. Several factors influence this, ensuring that the finished product meets aesthetic and functional standards.

(1)Surface defects of raw materials. Including issues like scratches, pitting, and pickling that can mar the final finish.

(2)The attributes of raw materials. Optimal hardness is key; too low and polishing becomes challenging, while deep drawing may result in undesirable surface textures like orange peel. Conversely, materials with higher hardness deliver better BQ properties.

(3)Deep-drawn products face unique challenges. Areas with significant deformation may develop small black spots and ridging, compromising the BQ performance essential for a pristine finish.

4. Heat resistance

Heat resistance denotes the ability of stainless steel to maintain its remarkable physical and mechanical properties at elevated temperatures, ensuring reliability in demanding environments.

The Role of Carbon: Carbon is a pivotal element in austenitic stainless steels, forming and stabilizing austenite while expanding its region. Its capacity to form austenite is about 30 times greater than nickel's. As an interstitial element, carbon significantly enhances the strength of austenitic stainless steel via solid solution strengthening and bolsters stress corrosion resistance in high-concentration chloride environments, like a 42% MgCl2 boiling solution.

| Product name | Stainless Steel Bars |

| Place of Origin | China |

| Application | Decoration, Kitchen, etc. |

| Thickness | As your requirement |

| Standard | JIS, ASTM EN JIS DIN GB |

| Length | 100mm-2500mm or as request |

| Certificate | API, ce, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 |

| Grade | 300 Series,400 Series,500 Series,600 Series |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Steel Grade | 301L, 301, 304N, 310S, 316L, 304, 304L, 430. etc |

| Delivery Time | 8-14 days |

| Type | Cold Rolled |

| Surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Shape | Bars |

Factory Direct: Experience over two decades of mastery in production and operations.

Flexible Production: We welcome both standard and small batch orders with open arms.

Quality Assurance: Proud to have successfully met and exceeded the international standard quality tests.

Around-the-Clock Support: Our dedicated team is at your service 24/7, ready to assist you anytime.

Swift Delivery: Enjoy lightning-fast delivery times, as quick as a mere seven days.

Comprehensive Service: From purchase to support, our one-step sales service guarantees exceptional after-sales care.

Zhongzheng Stainless Steel Co., Ltd. was established in 2018 with aregistered capital of 20 million yuan. lt is a manufacturing company thatintegrates the production of special materials, manufacturing andprocessing, sales, and technology development. The company covers anarea of 2,000 square meters and has 200 employees. it has built worldclass stainless steel seamless pipe (hot piercing, cold drawing, cold rollingproduction lines, precision steel pipe production lines, and large, mediumand small-sized welded pipe production lines. The company has beencommitted to providing high performance, high precision, hightemperature-resistant, high pressure-resistant, and corrosion-resistantsolutions and technical services for industrial equipment pipeline systems.The company specializes in producing a series of steel pipes, pipe fittingsflanges, etc., such as high-temperature (nickel-based) alloys, austeniticduplex steel, urea grade stainless steel, super stainless steel, etc. Thecompany is equipped with an annual production capacity of 5,000 tons ofstainless steel seamless pipe production line, 7,000 tons of welded pipeproduction line, and 500 tons of pipe fittings production line, etc. lt canoroduce stainless steel seamless pipes with diameters ranging from Φ6 toΦ762 and wall thicknesses ranging from 0.5 to 70 mm, stainless steelwelded pipes with diameters ranging from Φ15 to Φ2200 and wallthicknesses ranging from 0.5 to 80 mm, pipe fittings, and various stainlesssteel ingots, round steel, rough pipes, etc., according to customerrequirements and in accordance with standards such as GB, ASTM, etc.

What we offer:

1) Excellent quality control

2) Extremely competitive prices

3) Cutting-edge technology products

4) Seamless communication

5) Efficient OEM & ODM services

We proudly hold an array of prestigious quality system certifications, meticulously ensuring that only the finest, top-tier products are expertly delivered straight into your hands.

Our packaging ensures that your products arrive in pristine condition, as we offer a Standard Export Seaworthy Package. Additionally, we are flexible and can accommodate specific packaging requirements to meet your unique needs.

Send Inquiry to This Supplier

You May Also Like

-

High Temperature Resistant Inconel 625 Nickel Alloy Bar RodUS$ 1650 - 2650MOQ: 1 Meter

-

High Quality Machinery Industry Chemical Steel Pipe Stainless Round Inconel 625 RodsUS$ 1650 - 2650MOQ: 1 Meter

-

Nickel Alloy Inconel 625 Steel Tube Plate/Sheet Round Coil Strip Bar Manufacturer PriceUS$ 1650 - 2650MOQ: 1 Meter

-

Inconel 625 Bright Nickle Alloy Ingot Rod BarUS$ 1650 - 2650MOQ: 1 Meter

-

Top Quality Inconel 625 Round Bar RodUS$ 1650 - 2650MOQ: 1 Meter

-

Inconel 625 Stainless Steel Round Bar Used for Evaporators & ScrubbersUS$ 1650 - 2650MOQ: 1 Meter

-

Premium Nickel-Based Inconel 625 Alloy Steel Bar for Industrial UseUS$ 1650 - 2650MOQ: 1 Meter

-

Nickel Alloy Inconel 625 Round Bar/RodUS$ 1650 - 2650MOQ: 1 Meter

-

China Factory Manufacturer Price 2.4819 Nickel Alloy Inconel 625 Round Bar Price Per KgUS$ 1650 - 2650MOQ: 1 Meter

-

SUS304 316L 310S 2205 321 904L 316ti 630 2507 C276 316lvm Round Bar Bright Rod Stainless Steel Bar Bright Bar/RodUS$ 1650 - 2650MOQ: 1 Ton