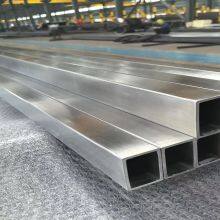

Precision Stainless Steel Square Tube Featuring Polishing, Annealing, and Pickling for Superior Surface Quality.

Engineered for industrial excellence, our precision stainless steel square tubes combine rigorous polishing, annealing, and pickling processes to deliver unmatched surface integrity. These structural components offer superior corrosion resistance and dimensional accuracy, making them ideal for demanding applications where material performance is non-negotiable. Manufactured under strict quality protocols, each tube guarantees consistent mechanical properties and aesthetic uniformity across production batches.

Core Technical Specifications:

- Material Science: Austenitic stainless steel grades (304/316) with 18-20% chromium content

- Surface Quality: Ra ≤ 0.4μm after multi-stage mechanical polishing

- Thermal Processing: Controlled annealing at 1010-1120°C followed by rapid quenching

- Chemical Treatment: Acid pickling with HNO3/HF solution to remove scale

- Structural Integrity: Tensile strength 515-620 MPa, yield strength ≥205 MPa

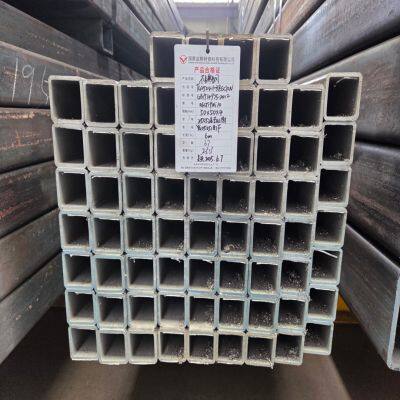

| Cross-Section (mm) | Wall Thickness (mm) | Standard Length | Weight per Meter (kg) |

|---|---|---|---|

| 25×25 | 1.5 | 6m | 1.12 |

| 50×50 | 2.0 | 6m | 3.01 |

| 100×100 | 4.0 | 6m | 12.20 |

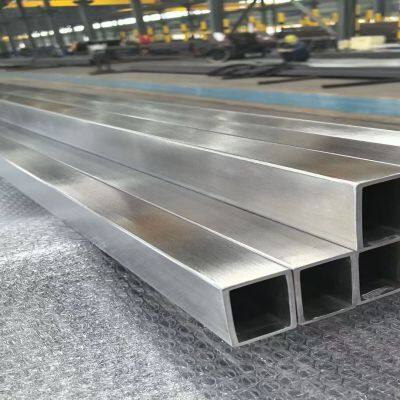

Performance Advantages:

• Enhanced corrosion resistance in chloride environments due to pickling-induced passive layer formation

• Improved machinability and weldability from stress-relieving annealing process

• Reduced friction coefficients (up to 40% improvement) through precision polishing

• Consistent dimensional tolerances maintained within ±0.05% across production runs

Industrial Implementation Benefits:

- Architectural applications: Reduced maintenance costs in structural frameworks exposed to weather elements

- Food processing equipment: Meets sanitary surface requirements with non-porous finish

- Chemical transport systems: Extended service life in corrosive material handling

Optimize your project specifications with tubing solutions that undergo 27 quality checkpoints during manufacturing. Our integrated polishing-annealing-pickling sequence ensures metallurgical properties meet international standards for critical applications. Contact our engineering team for material certifications and custom dimensional requirements.

Frequently Asked Questions

Q: How does pickling improve corrosion resistance?

A: The acid treatment removes iron contaminants and forms a chromium-rich passive layer that inhibits oxidation.

Q: What temperature ranges can these tubes withstand?

A: Annealed grades maintain structural integrity between -200°C and 800°C depending on specific alloy composition.

Q: Are custom cross-sections available?

A: Rectangular and square profiles from 10mm to 200mm can be produced with wall thickness adjustments.

Q: How does polishing affect surface roughness?

A: Our mechanical polishing achieves surface finishes of 0.2-0.8μm Ra, reducing particulate adhesion.

Q: What packaging options are provided?

A: Tubes are typically bundled in moisture-proof wrapping with corner protectors for international shipping.

Send Inquiry to This Supplier

You May Also Like

-

Durable Stainless Steel Square Tube With Annealing Process, Ideal for Industrial Equipment and Fabrication.NegotiableMOQ: 1 Ton

-

ASTM A554 304 201 Stainless Steel Round Tube for Automotive Exhaust System and Decoration, Reliable ManufacturerNegotiableMOQ: 1 Ton

-

Construction Grade Stainless Steel Round Pipe for Building Infrastructure and Structural ProjectsNegotiableMOQ: 1 Ton

-

Precision Stainless Steel Round Pipe Compatible With Standard Fittings for Easy InstallationNegotiableMOQ: 1 Ton

-

Stainless Steel Round Pipe - Various Sizes From 1/4" to 12" Diameter for Custom Industrial ApplicationsNegotiableMOQ: 1 Ton

-

Durable Stainless Steel Round Pipe for Automotive and Marine Applications With Custom Length OptionsNegotiableMOQ: 1 Ton

-

Large Stock 304 316 310S Stainless Steel Round Pipe, for Heat Exchanger Tube and Petrochemical Industry From MillNegotiableMOQ: 1 Ton

-

Corrosion-Resistant Stainless Steel Round Pipe With Long Service Life and Low MaintenanceNegotiableMOQ: 1 Ton

-

Premium Stainless Steel Round Pipe for Construction, Automotive, and Chemical IndustriesNegotiableMOQ: 1 Ton

-

Durable Stainless Steel Round Pipe for Plumbing, HVAC, and Structural ApplicationsNegotiableMOQ: 1 Ton