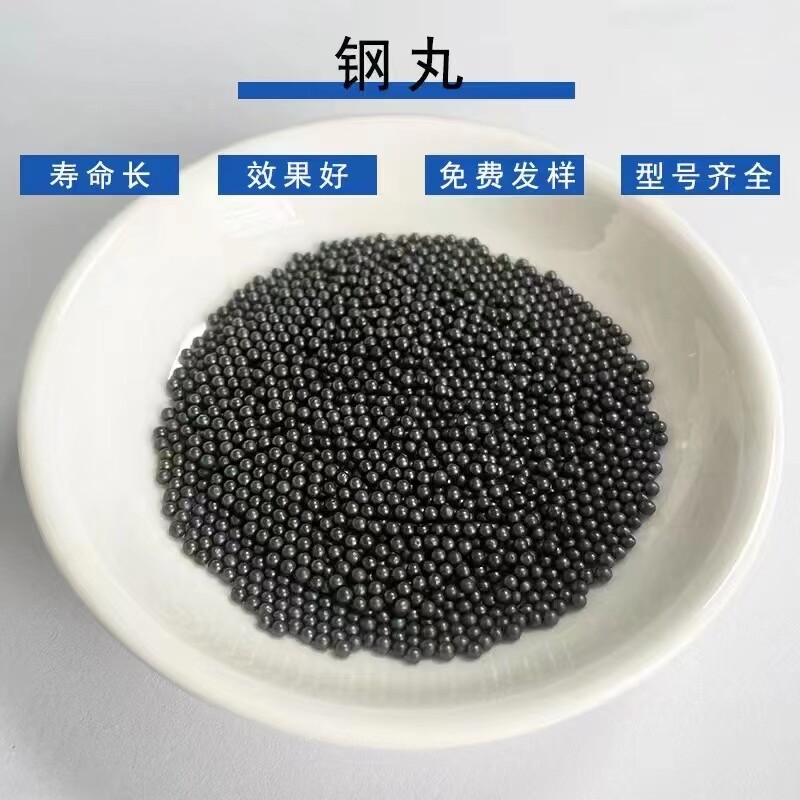

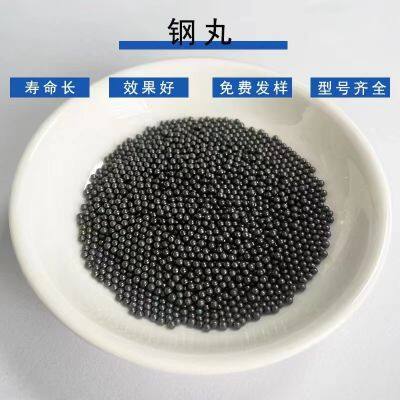

Cast Steel Shot/Alloy Steel Shot Wholesale: Stable Hardness, Low Wear Rate, Long-term Cooperation Offers Even Better Prices

Steel shot is a commonly used material for treating metal parts. The steel shot has a tight structure and uniform particle size. Treating the surface of metal parts with steel shot can increase the surface pressure of the metal parts, thereby greatly improving their fatigue resistance. The use of steel shot for surface treatment of metal parts has the advantage of fast cleaning speed. The steel shot and steel sand have appropriate hardness and good rebound properties. They can evenly and quickly clean corners and complex-shaped parts, thereby shortening the surface treatment time, improving work efficiency, and being a good material for surface treatment.

Steel shot is a commonly used surface treatment material, and there are numerous types of steel shot. The materials and equipment required also vary depending on the type of steel shot. Here are the main characteristics of steel shot:

Steel shot is a high-quality wear-resistant material. It has an appropriate hardness and strong toughness, with excellent impact resistance and a long service life. It exhibits excellent rebound properties, allowing for fast cleaning with low consumption. Steel shot has a wide range of applications, including the surface treatment of cast and forged parts, as well as parts after machining and heat treatment. Steel shot and steel sand are commonly used in various industries, such as general manufacturing and shipbuilding.

Send Inquiry to This Supplier

You May Also Like

-

(Cast Steel Shot/Alloy Steel Shot Abrasive Blasting) High-hardness Abrasive Material, Effective Improvement in Metal Rust Removal Efficiency.NegotiableMOQ: 25 Metric Tons

-

Rust Removal Abrasive Cast Steel Shot/Alloy Steel Shot: Durable and Impact-Resistant - Long-Lasting Solution for Surface Treatment via Shot BlastingNegotiableMOQ: 25 Metric Tons

-

Cast Steel Shot vs Traditional Abrasive: More Thorough Rust Removal, Reduced Consumption by 30%NegotiableMOQ: 25 Metric Tons

-

Applicable to Shot Peening Machines and Sandblasting Chambers; a Complete Range of Models, Including S110-S930, Suitable for Various Equipment.NegotiableMOQ: 25 Metric Tons

-

High-hardness, High-toughness Cast Steel Shot/alloy Steel Shot is the First Choice for Shot Blasting Rust Removal, Offering a Long LifespanNegotiableMOQ: 25 Metric Tons

-

Abrasive Blasting for Rust Removal Using Lotus Seed-shaped Abrasive Particles/cast Steel Abrasive Particles, Highly Durable and Efficient.NegotiableMOQ: 25 Metric Tons

-

Abrasive Material for Rust Removal and Surface Grinding: High-hardness Cast Steel Sand/angled Steel Sand.NegotiableMOQ: 25 Metric Tons

-

High-hardness Cast Steel Abrasive GH40 (0.7mm) Angular Steel Abrasive for Sandblasting, Polishing, and Rust Removal.NegotiableMOQ: 25 Metric Tons

-

Cast Steel Sand/Wedge-Shaped Steel Sand Abrasive: Extremely High Hardness, Quick and Thorough Rust Removal Through Blasting!NegotiableMOQ: 25 Metric Tons

-

Abrasive Material: Wire Cut Shot With a Length of Around 3.0 mm and a Diameter of 1.5 Mm.NegotiableMOQ: 25 Metric Tons