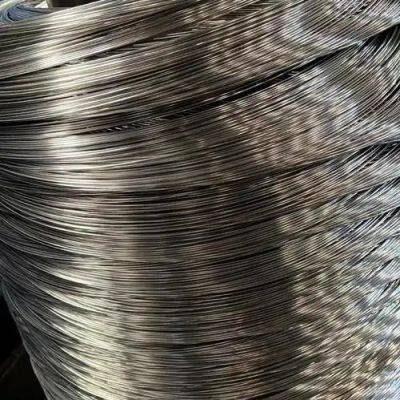

High-Strength Stainless Steel Wire Compatible With Welding and Fabrication Processes

Engineered for precision joining and industrial fabrication, our high-strength stainless steel wire delivers exceptional performance in demanding manufacturing environments. Specially formulated to maintain structural integrity under thermal stress, this wire solution addresses critical challenges in metal joining applications. With ISO9001-certified quality assurance, we ensure batch-to-batch consistency for your production workflows.

Discover the technical advantages that make this welding wire indispensable:

- Superior arc stability during continuous welding operations

- Optimized feedability in automated welding systems

- Low spatter generation reducing post-processing requirements

- Exceptional corrosion resistance in harsh environments

Typical mechanical specifications include:

| Property | Value Range |

| Yield Strength | 650-850 MPa |

| Elongation at Break | 15-25% |

| Hardness (HV) | 200-250 |

The wire's metallurgical composition ensures minimal porosity in welds while providing excellent penetration characteristics. Available in industry-standard packaging configurations, our wire supports just-in-time manufacturing with reliable supply chain solutions through major ports including Shanghai and Tianjin.

Manufactured with tight diameter tolerances (±0.02mm), this product guarantees consistent performance across robotic welding cells and manual operations. The bright annealed surface finish reduces feeding friction in welding torches while preventing surface contamination.

Key application sectors:

- Structural steel fabrication

- Pressure vessel manufacturing

- Automotive component production

- Marine equipment assembly

With dedicated technical support and global logistics capabilities, we deliver tailored solutions to manufacturing operations worldwide. Our overseas offices ensure responsive communication and local inventory management for critical production requirements.

Contact our metallurgical specialists today to discuss how our high-performance welding wire can optimize your fabrication processes and reduce production costs.

Frequently Asked Questions

Q: What stainless steel grades are available?

A: We offer multiple stainless steel formulations suitable for different applications. Contact our team for specific grade availability.

Q: What packaging options do you provide?

A: Standard packaging includes 15kg spools and 500kg coils. Custom packaging configurations are available upon request.

Q: Can this wire be used for underwater welding?

A: While offering excellent corrosion resistance, special formulations may be required for submerged applications. Consult our technical team for project-specific recommendations.

Q: Do you provide welding parameter guidelines?

A: Comprehensive welding procedure specifications are available for all our wire products to ensure optimal results.

Q: What is your lead time for custom orders?

A: Standard lead times range from 4-6 weeks for specialized formulations, depending on order volume and complexity.

Send Inquiry to This Supplier

You May Also Like

-

China Manufacturer Supply Medical-Grade Stainless Steel Wire Designed for Healthcare and Dental IndustriesNegotiableMOQ: 1 Ton

-

Stainless Steel Welding Wire for Industrial Equipment Maintenance - Manufacturer DirectNegotiableMOQ: 1 Ton

-

Versatile Stainless Steel Wire for Automotive and Marine Environments Offering LongevityNegotiableMOQ: 1 Ton

-

Industrial-Grade Stainless Steel Wire Featuring High Durability and Low MaintenanceNegotiableMOQ: 1 Ton

-

Premium Nickel GH4145 N08020 Based Alloy Plate for Oil and Gas Industry Equipment and ComponentsNegotiableMOQ: 1 Ton

-

Precision-Cut Inconel800 800H 825 Nickel Based Alloy Plate Compatible With Chemical Processing StandardsNegotiableMOQ: 1 Ton

-

Corrosion-Resistant Nickel Based Alloy Plate Inconel800 800H 825 With Superior Heat Tolerance and DurabilityNegotiableMOQ: 1 Ton

-

High-Performance GH4145 N08020 Nickel Based Alloy Plate Ideal for Aerospace and Defense ApplicationsNegotiableMOQ: 1 Ton

-

GH3128 Nickel Based Alloy Plate in Various Sizes and Thicknesses for Custom Industrial FabricationNegotiableMOQ: 1 Ton

-

304 Stainless Steel Coil With 0.5mm Thickness and 1000mm Width for Precision ManufacturingNegotiableMOQ: 1 Ton