Compact Bridge Tractor for Cable Laying in Confined Spaces With Gasoline Engine and 4-Speed Gearbox

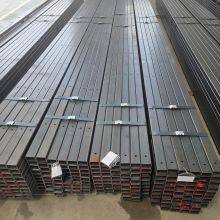

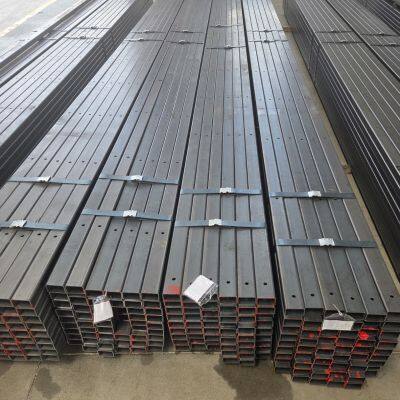

Introducing the Compact Bridge Tractor – an engineering breakthrough for cable installation in confined spaces like bridge structures, tunnels, and elevated cable trays. Designed for contractors facing spatial constraints, this gasoline-powered machine delivers exceptional maneuverability without compromising on pulling power. Its compact footprint (just 2020x1570x1170mm) allows deployment where traditional equipment cannot operate, while the 4-speed gearbox provides precise control over cable tensioning operations.

Unlike bulkier alternatives, this tractor features patent-pending foldable components including support rods and telescopic footrests that stabilize the unit during operation. The innovative track transmission system ensures minimal cable slippage even at maximum load capacity of 30KN. For projects demanding silent operation or indoor use, note that diesel and electric variants are available upon request.

Core Technical Advantages:

- Space-Optimized Design: 30% smaller profile than industry standards enables vertical/horizontal mounting on bridge girders or narrow cable trays

- Intelligent Force Distribution: Dual-track transmission reduces point pressure on cables by 45%, preventing insulation damage

- Rapid Cable Loading System: Upper transmission lifts via rotating handle for tool-free cable insertion/removal in under 15 seconds

- Multi-Terrain Mobility: Integrated traveling wheels + optional "auto-walk" function for effortless repositioning

| Parameter | Specification | Testing Standard |

|---|---|---|

| Gear Configuration | Fast / Slow / Neutral / Reverse | ISO 9001-2015 (Factory Calibration) |

| Track Material | Reinforced Rubber Composite (Oil/Heat Resistant) | ASTM D2000 M2BG 714 |

| Max Incline Operation | 35° Slope (with Extended Footrest) | Field Test Protocol CY-TP07 |

| Fuel Consumption | 1.8 L/hour @ Full Load | SAE J1349 Engine Certification |

Operational Flexibility: The gearbox allows instant switching between traction modes – use "Fast" for straight cable pulls up to 200 meters, "Slow" for precision alignment in bends, or "Reverse" for effortless cable retrieval. Remote control capability (optional) enables solo operation from up to 300m away, critical for tunnel applications where operator mobility is restricted.

Maintenance & Safety Highlights:

- Self-Diagnostic Port: Integrated OBD-II connector for real-time monitoring of engine health and track tension

- Overload Protection: Automatic engine cutoff when traction exceeds 110% rated capacity

- Quick-Release Track System: Replace worn belts in 8 minutes without disassembling transmission

- Thermal Management: Directional cooling fins prevent surface temperatures exceeding 65°C during continuous operation

Frequently Asked Questions:

Q1: Can this tractor handle steel strand cables?

A: Not recommended – the reinforced rubber tracks experience accelerated wear with steel strands. Use only for fiber optic/polymer-sheathed cables.

Q2: What's the minimum working width required?

A: 700mm clearance is sufficient for deployment, including operator access space.

Q3: Is the gasoline engine suitable for indoor tunnels?

A: We recommend our electric variant for enclosed spaces – contact us for ventilation requirements of gasoline models.

Q4: How often should track tension be checked?

A: Inspect every 40 operational hours using the built-in tension gauge. Adjust via side bolts if deflection exceeds 5mm.

Q5: Can multiple units be synchronized?

A: Yes – up to 8 tractors can be linked via wireless control for coordinated long-distance pulls.

Final Recommendation: This tractor reduces cable installation time by up to 60% in bridge/tunnel projects compared to manual methods. Extended 2-year warranty available for fleet purchases – request a performance demo video via our contact page. All units include multilingual manuals and lifetime technical support.

⚠️ Critical Note: Always operate with provided safety harnesses when mounted on vertical surfaces. Never exceed 35° inclination without extended footrest deployment.

Send Inquiry to This Supplier

You May Also Like

-

Multi-Function Bridge Tractor Featuring Track Transmission System for Stable Fiber Optic Cable InstallationUS$ 2500.00MOQ: 1 Acre

-

Home Use Beer Brewing Equipment Kit for Craft Beer Enthusiasts and BeginnersNegotiableMOQ: 1 Unit

-

Compact Size Beer Brewing Equipment Ideal for Small-Scale Operations With Limited SpaceNegotiableMOQ: 1 Unit

-

Stainless Steel Beer Brewing Equipment With 50L Capacity for Commercial BreweriesNegotiableMOQ: 1 Unit

-

High-Efficiency Beer Brewing Equipment Featuring Automated Temperature Control SystemsNegotiableMOQ: 1 Unit

-

Professional Beer Brewing Equipment Designed for Microbreweries and Brew PubsNegotiableMOQ: 1 Unit

-

Heavy-Duty Bridge Tractor With 30KN Tractive Force for Long-Distance Cable Pulling in Mountainous AreasUS$ 2500.00MOQ: 1 Acre

-

BNC Female Three Sets Connector for Multi-Port ApplicationsUS$ 2500.00MOQ: 1 Acre

-

Portable Bamboo Winch 1155kg Weight With Dual-Function Traction/Reeling System for Rugged AreasUS$ 1100MOQ: 1 Acre

-

BNC Male Crimp Type Connector A:RG58 B:RG59 C:RG6US$ 2500.00MOQ: 1 Acre