Home > Products > Seamless Steel Pipe > Heat Exchanger Tube A335 P9 Alloy Tube High Strength Corrosion Resistant Power Plant Systems

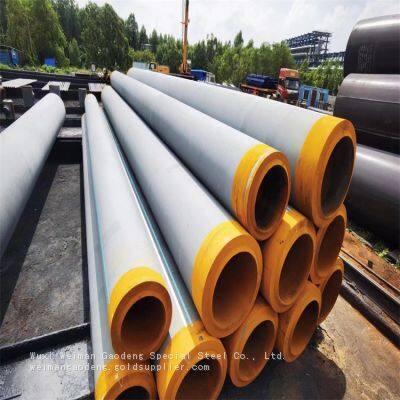

Heat Exchanger Tube A335 P9 Alloy Tube High Strength Corrosion Resistant Power Plant Systems

- Shanghai

- T/T L/C

- 1 days

You May Like

-

Alloy Steel Pipe 1.4903 Seamless Pipe High Temperature Bearing Precision Dimension Industrial Boilers

-

Smooth Inner Wall High-temperature Tolerant Tubes, 304 & S30400 Austenitic Stainless Steel Seamless Steel Tubes

-

Corrosion Resistant Precision Size Tubes, 1.4301 & 304H Ferritic Stainless Steel Boiler Tubes

-

Anti-oxidation High-pressure Applicable Tubes, S30409 & 1.4948 Seamless Stainless Steel Heat Exchanger Tubes

-

Wear Resistant Dimensional Stable Tubes, 304L & S30403 Austenitic Stainless Steel Superheater Tubes

-

Heat Resistant Thick Wall Tubes, 1.4307 & 304LN Ferritic Stainless Steel Steel Tubes for High-temperature Applications

Product Details

| Type | Seamless | Warranty | a year | |

| Technique | Hot Rolled | Surface Treatment | Black | |

| Usage | Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry, Chemical Industry, Mining | Material | Carbon Steel | |

| Section Shape | Round | Execution standard | ASTM、ASME | |

| Transport Package | waterproof cloth | Specification | 19.05-1220 | |

| Origin | China |

Product Description

Weiman Gaodeng Special Steel Seamless Steel Pipe

Alloy Steel Pipes & Seamless Tubes Product DetailsCore Selling Points

• Multi-material coverage: Complies with ASTM and EN standards, including A213 T5/P5, T9/P9, T11/P11, T12/P12, T22/P22, T91/P91, T92/P92, 1.7362, 1.7386, 1.4903, 1.4901, 1.4922, X20CrMoV11-1.

• High-performance adaptation: Resistant to high temperature, corrosion, and pressure; wear-resistant with stable structural strength for extreme working conditions.

• Precision manufacturing: Strict dimensional tolerance control, seamless forming process, and consistent product quality for industrial reliability.

Material SpecificationsASTM Standard Materials

• A213 Series: T5, T9, T11, T12, T22, T91, T92 (seamless tubes for boilers and heat exchangers)

• A335 Series: P5, P9, P11, P12, P22, P91, P92 (alloy steel pipes for high-temperature and high-pressure service)

EN Standard Materials

• 1.7362, 1.7386, 1.4903, 1.4901, 1.4922, X20CrMoV11-1 (European standard alloy steel tubes for industrial thermal equipment)

Product Range & Applications

Product Type | Typical Applications |

Boiler Pipe | Industrial boilers, power plant boilers, thermal power generation systems |

Heat Exchanger Pipe | Chemical industry heat exchangers, refrigeration equipment, thermal transfer systems |

Water Wall Tube | Boiler water wall systems, high-temperature furnace heating surfaces |

Superheater Pipe | Power plant superheaters, reheaters, high-temperature steam pipelines |

High Temperature Seamless Pipe | High-temperature industrial pipelines, petrochemical cracking units |

Alloy Steel Pipe/Tube | Industrial piping systems, pressure vessels, heavy machinery components |

Product Advantages

1. Performance Stability: Formulated with high-quality alloy elements, the products maintain mechanical properties at temperatures up to 650℃, with excellent oxidation and creep resistance.

2. Precision Craftsmanship: Adopts hot rolling + cold drawing process, with dimensional accuracy up to ±0.05mm, ensuring tight fitting with equipment components.

3. Corrosion Resistance: The alloy composition effectively resists corrosion from steam, chemical media, and acidic/alkaline environments, extending service life.

4. Wide Compatibility: Suitable for power generation, petrochemical, chemical, metallurgical, and other industries, matching various thermal equipment requirements.

Technical Parameters

• Operating Temperature Range: -20℃ to 650℃

• Pressure Bearing Capacity: Up to 35MPa (depending on material and specification)

• Size Range: Outer diameter 10mm-1016mm, wall thickness 1mm-200mm (customizable)

• Execution Standards: ASTM A213, ASTM A335, EN 10216-2, DIN 17175

• Surface Treatment: Annealed, pickled, passivated, or as per customer requirements

Order Information

• Customization: Accepts non-standard size, material combination, and surface treatment customization.

• Quality Assurance: 100% raw material inspection, dimensional testing, and performance verification before delivery; provides material certification (MTC).

• Delivery Cycle: 7-20 working days (varies by order quantity and specification).

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1. Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2. Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3. Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4. Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameMolly Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu, China

Product Categories

New Products

-

Pressure Resistant Smooth Surface Tubes, S30453 & 1.4311 Seamless Steel Heat Exchanger Tubes

-

High-strength Temperature Resistant Tubes, Super304 & S30432 Austenitic Stainless Steel Boiler Tubes

-

Anti-fatigue Corrosion Proof Tubes, 321 & S32100 Ferritic Stainless Steel Seamless Stainless Steel Tubes

-

Dimensional Precision Heat Resistant Tubes, 1.4541 & 321H Austenitic Stainless Steel Superheater Tubes

-

Smooth Outer Wall High-temperature Tubes, S32109 & 1.4940 Seamless Steel Boiler Tubes for High-temperature Service

-

Corrosion Resistant High-pressure Tubes, 316L & S31603 Ferritic Stainless Steel Heat Exchanger Tubes

-

High-temperature Tolerant Anti-oxidation Tubes, 1.4404 & 316LN Austenitic Stainless Steel Seamless Steel Tubes

-

Wear Proof Precision Size Tubes, S31653 & 1.4406 Ferritic Stainless Steel Superheater Tubes

-

Pressure Applicable Heat Resistant Tubes, 316Ti & S31635 Seamless Stainless Steel Boiler Tubes

-

Anti-corrosion High-strength Tubes, 1.4571 & 316LMoD Austenitic Stainless Steel Heat Exchanger Tubes

-

Temperature Resistant Smooth Inner Tubes, 316LUG & 1.4435 Ferritic Stainless Steel Steel Tubes for High-temperature Use

-

Dimensional Stable Corrosion Resistant Tubes, 317L & S31703 Seamless Steel Superheater Tubes

-

High-pressure Tolerant Wear Resistant Tubes, 1.4438 & 310S Austenitic Stainless Steel Boiler Tubes

-

Heat Proof Anti-fatigue Tubes, S31008 & 1.4845 Ferritic Stainless Steel Seamless Stainless Steel Tubes

-

Smooth Surface High-temperature Tubes, 314 & 1.4841 Seamless Steel Heat Exchanger Tubes for High-temperature Applications

-

Corrosion Proof Precision Tubes, 310MoLN & S31050 Austenitic Stainless Steel Superheater Tubes

-

High-strength Pressure Resistant Tubes, 1.4466 & 310HCbN Ferritic Stainless Steel Boiler Tubes

-

Anti-oxidation Temperature Tolerant Tubes, S31042 & 347H Seamless Steel Seamless Steel Tubes

-

Wear Resistant Heat Resistant Tubes, S34709 & 1.4942 Austenitic Stainless Steel Heat Exchanger Tubes

-

Precision Size High-pressure Tubes, 347HFG & S34710 Ferritic Stainless Steel Superheater Tubes for High-temperature Service

-

Smooth Inner Wall Corrosion Resistant Tubes, 904L & N08904 Seamless Stainless Steel Boiler Tubes

-

High-temperature Resistant Dimensional Tubes, 1.4539 & S31254 Austenitic Stainless Steel Steel Tubes

-

Anti-fatigue Corrosion Proof Tubes, 1.4547 & N08367 Ferritic Stainless Steel Heat Exchanger Tubes

-

Pressure Resistant Wear Proof Tubes, N08926 & 1.4529 Seamless Steel Superheater Tubes

Popular Searches

- tube pipe

- steel round pipe

- stainless steel seamless pipe

- alloy steel seamless pipe

- pipe fitting

- stainless steel

- steel pipe

- carbon steel

- tube pipe

- steel tube

- seamless steel pipe

- seamless pipe

- stainless steel pipe

- heat exchanger tube

- seamless stainless steel pipe

- steel tube pipe

- seamless tube

- alloy steel pipe

- oil casing

- oil pipe

- alloy pipe

- boiler tube

- boiler steel pipe

- steel erw

- stainless steel

- steel pipe

- copper pipe

- tube pipe

- coil pipe

- seamless steel pipe

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Pipe & Tube

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Molly

Hi there! Welcome to my shop. Let me know if you have any questions.

Molly

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile