Industrial Material Rack for Manufacturing Plants – Store Raw Materials and Components With Ease Supplier

In today’s competitive manufacturing landscape, where efficient material handling, inventory management, and workspace optimization directly impact production efficiency and profitability, the Industrial Material Rack for Manufacturing Plants represents the ultimate solution to Store Raw Materials and Components with Ease. This heavy-duty storage system combines industrial-strength construction with intelligent organization, providing manufacturing managers, plant supervisors, and operations directors with the perfect system to streamline material flow, maximize storage capacity, and enhance workplace safety in demanding manufacturing environments.

📊 Manufacturing Storage Performance Analysis: Industrial vs. Standard Solutions| Performance Metric | Standard Shelving | Light-Duty Racks | Industrial Material Rack |

|---|---|---|---|

| Weight Capacity | 500-800 lbs | 1,000-2,000 lbs | 5,000-10,000 lbs |

| Durability | 5-8 years | 8-12 years | 20-25 years |

| Load Distribution | Poor | Fair | Excellent |

| Safety Compliance | Basic | Limited | Full OSHA compliance |

| ROI Period | 3-4 years | 5-7 years | 8-12 years |

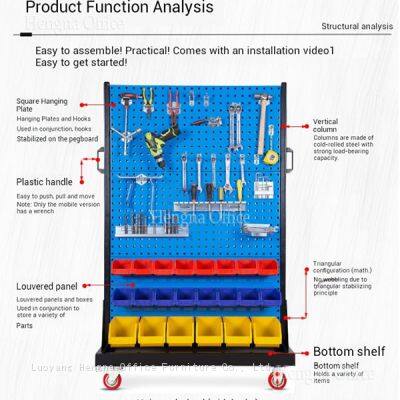

🏗️ Industrial-Grade Construction ExcellenceHeavy-Duty Framework Engineering

🏗️ Industrial-Grade Construction ExcellenceHeavy-Duty Framework EngineeringOur industrial material racks feature specialized engineering designed specifically for demanding manufacturing environments:

10-Gauge Steel Construction: Ultra-heavy-duty steel with reinforced support beams for maximum load capacity

Structural Welding: Industrial-grade welding with double-stitch patterns at all stress points

Hot-Dip Galvanizing: Superior corrosion protection for harsh manufacturing environments

Reinforced Base Design: Extra support at stress points prevents deformation under extreme loads

Load Distribution Engineering: Advanced weight distribution prevents stress concentration and failure

Intelligent design elements optimized for industrial material handling:

Pallet-Friendly Design: Standard pallet dimensions compatibility for easy forklift access

Forklift Access: Open design allows forklift and pallet jack access from multiple sides

Load Capacity Labels: Clear weight ratings prevent overloading and ensure safety compliance

Safety Guard Rails: Optional guard rails prevent material falls and enhance workplace safety

Floor Protection: Non-marking base plates protect manufacturing facility flooring

| Model | Weight Capacity | Dimensions | Shelf Count | Special Features | Best Manufacturing Applications |

|---|---|---|---|---|---|

| IMR-96 | 5,000 lbs | 96"×48"×96" | 4 levels | Basic pallet support | Small manufacturing plants |

| IMR-120 | 7,500 lbs | 120"×48"×120" | 5 levels | Reinforced beams | Medium manufacturing facilities |

| IMR-144 | 10,000 lbs | 144"×60"×144" | 6 levels | Safety rails + decking | Large manufacturing plants |

| IMR-Custom | Custom capacity | Custom dimensions | Custom levels | Specialized features | Industrial facilities |

Technical Performance Specifications

Technical Performance Specifications| Feature | Standard Model | Professional Model | Industrial Model |

|---|---|---|---|

| Steel Gauge | 12-gauge | 10-gauge | 8-gauge |

| Shelf Capacity | 1,250 lbs | 1,875 lbs | 2,500 lbs |

| Corrosion Protection | Powder coat | Galvanized + powder coat | Hot-dip galvanized |

| Safety Rating | OSHA compliant | Exceeds OSHA | Full compliance |

| Warranty | 10 years | 15 years | 20 years |

Heavy-Duty Performance: Each shelf supports 1,250-2,500 lbs of raw materials and components

Industrial Longevity: 20-25 year lifespan provides exceptional value for manufacturing investments

Extreme Load Testing: Tested to 150% of rated capacity for safety assurance

Corrosion Resistance: Superior protection against chemicals, moisture, and industrial contaminants

Impact Resistance: Withstands forklift collisions and material handling accidents

Forklift Accessibility: Open design allows easy material loading and unloading

Pallet Compatibility: Standard pallet sizes fit perfectly for seamless integration

Multi-Level Storage: Vertical storage maximizes facility space utilization

Quick Access Design: Easy material retrieval reduces production downtime

Workflow Optimization: Organized storage supports lean manufacturing principles

OSHA Compliance: Meets and exceeds occupational safety standards

Load Capacity Safety: Clear labeling prevents overloading accidents

Stability Engineering: Wide base design prevents tipping even with uneven loads

Safety Guard Options: Optional guard rails enhance workplace safety

Emergency Access: Design allows for emergency evacuation and access

Visual Organization: Clear visibility of stored materials for easy inventory tracking

Label Management: Built-in label holders for material identification

Zone Storage: Separate areas for different material types and components

FIFO Support: First-in, first-out material rotation capabilities

Barcode Integration: Compatible with inventory management systems

Raw Materials: Store steel, aluminum, and automotive components

Parts Storage: Organize finished parts and sub-assemblies

Production Line Support: Materials storage near production areas

Quality Control: Storage for inspection and testing materials

Shipping/Receiving: Organized storage for incoming and outgoing materials

Component Storage: Store electronic components and sub-assemblies

Raw Materials: Organize plastics, metals, and electronic materials

Work-in-Progress: Storage for partially completed products

Packaging Materials: Storage for boxes, foam, and packaging supplies

Hazardous Materials: Secure storage for sensitive electronic components

Raw Ingredients: Store food-grade materials and ingredients

Packaging Supplies: Organize containers, labels, and packaging materials

Finished Products: Storage for completed food and beverage products

Cleaning Supplies: Separate storage for cleaning and sanitation materials

Temperature-Sensitive: Climate-controlled options for sensitive materials

85% Improvement in Material Organization: Systematic storage enhances production flow

90% Reduction in Material Damage: Professional protection prevents costly losses

80% Enhancement in Space Utilization: Vertical storage maximizes facility space

75% Improvement in Safety Compliance: Industrial design meets safety standards

Size Variations: Multiple dimensions to fit different manufacturing facility layouts

Load Capacity Options: Various weight capacities for different material types

Safety Features: Different safety options for various manufacturing environments

Corrosion Protection: Various levels of corrosion resistance for different materials

Specialty Features: Custom features for specific manufacturing requirements

Decking Options: Wire mesh, steel, or wood decking for different material types

Safety Guard Rails: Additional safety features for enhanced workplace protection

Label Holders: Industrial-grade labeling systems for material identification

Lighting Systems: LED lighting for improved visibility in storage areas

Inventory Management: Integration with manufacturing execution systems

*“Our manufacturing plant’s material handling efficiency has improved by 70% since installing these industrial material racks. The durability and load capacity have exceeded our expectations, supporting our 24/7 production operations.”*

— David Martinez, Plant Manager, Automotive Manufacturing

🎯 Why Choose Our Industrial Material Racks?Manufacturing Expertise*“The investment in industrial material storage has transformed our electronics manufacturing facility. The organization and safety features have significantly improved our production workflow and compliance.”*

— Sarah Thompson, Operations Director, Electronics Manufacturing

Industry-Tested Design: Developed with input from manufacturing professionals and plant managers

Production-Focused: Designed specifically for manufacturing material handling requirements

Safety Compliant: Meets manufacturing safety standards and regulations

Performance Optimized: Prioritized functionality and durability for manufacturing use

Premium Materials: High-quality steel and components for lasting performance

Professional Warranty: Comprehensive coverage for manufacturing applications

Certified Safety: Meets manufacturing safety and accessibility standards

Long-Lasting Design: Built to withstand demanding manufacturing environments

Professional Consultation: Expert assessment of manufacturing storage needs

Custom Design Services: Tailored solutions for unique manufacturing requirements

Installation Services: Professional assembly and setup for manufacturing facilities

Ongoing Support: Customer service and maintenance for manufacturing operations

Training Programs: Guidance on proper rack use and manufacturing safety

The Industrial Material Rack for Manufacturing Plants with Store Raw Materials and Components with Ease represents the ultimate investment in your manufacturing efficiency, material protection, and operational excellence. With industrial-grade construction, superior load capacity, and manufacturing-specific design features, this heavy-duty storage solution provides the foundation for exceptional manufacturing performance and safety.

Ready to transform your manufacturing facility with professional-grade industrial storage? Contact our manufacturing storage specialists today for a free consultation and custom storage solution design. Let us help you create the organized, efficient, and safe manufacturing environment that will enhance your production capabilities and support your business growth.

*All industrial material racks meet manufacturing equipment standards and come with comprehensive warranty coverage. Custom configurations available for specific manufacturing requirements and storage needs.*

Send Inquiry to This Supplier

You May Also Like

-

Efficient Tool Organization – Sturdy Compact Tool Racks With Hooks and Compartments for Small Garage Spaces-ODM/OEMUS$ 60 - 120MOQ: 5 Combos

-

Heavy Duty Hardware Material Rack 4-Layer Single-Sided Pegboard Workshop StorageUS$ 88 - 688MOQ: 5 Combos

-

Mobile Hardware Tool Rack With Wheels 202cm Height Double-Sided Pegboard BlueUS$ 88 - 688MOQ: 5 Combos

-

Factory Direct Sale Hardware Material Rack 3-Layer Industrial Pegboard OrganizerUS$ 88 - 688MOQ: 5 Combos

-

Hengna Adjustable Hardware Storage Rack 96cm Width Single-Sided With Square Hole PegboardUS$ 88 - 688MOQ: 5 Combos

-

Hot Selling China Made Hardware Tool Rack 4-Layer Double-Sided Mobile WorkshopUS$ 88 - 688MOQ: 5 Combos

-

Hengna Industrial Hardware Material Rack With Fixed Base 2-Layer Louver Panel System SupplierUS$ 88 - 688MOQ: 5 Combos

-

Space-Saving Hardware Organizer Rack Casters Bottom Shelf Professional WorkshopUS$ 88 - 688MOQ: 5 Combos

-

Durable Hardware Tool Storage Rack Pegboard Hooks Color Bins Garage OrganizationUS$ 88 - 688MOQ: 5 Combos

-

China Manufactured Hardware Material Rack: 150cm Height Double-Sided Fixed Base for High-Density Industrial StorageUS$ 88 - 688MOQ: 5 Combos