MAR-M247 Cast High-temperature Alloy, MARM200, MARM246 High-temperature Resistant and High-strength

MAR-M247 cast high-temperature alloy, MARM200, MARM246 high-temperature resistant and high-strength

MAR-M247 is a nickel-based precipitation-strengthened cast superalloy designed for extreme high-temperature, high-stress, and complex corrosive environments. It is widely used in high-temperature components in aerospace, gas turbine, and energy fields.

MAR-M247 exhibits superior performance at high temperatures:

• Oxidation resistance: After long-term aging at 900℃ (up to 8000 hours), a multi-layered oxide film primarily composed of Al₂O₃ forms on the surface. Over time, the inner Al₂O₃ film becomes thicker, more continuous, and denser, significantly improving the alloy's oxidation resistance. However, the initially formed W-rich oxide layer may be porous and prone to peeling.

• Hot corrosion resistance: It exhibits good resistance to hot corrosion (such as sulfate deposition corrosion).

Heat Treatment Process

Heat treatment is crucial for maximizing the performance of MAR-M247. Typical specifications are as follows:

• Solution Treatment: Typically, heating and holding at 1200-1250℃ (e.g., 2-6 hours) aims to dissolve the γ' phase and certain carbides, obtaining a homogeneous supersaturated solid solution. Higher solution temperatures (e.g., 1260℃) help dissolve more primary γ' and eutectic phases, but strict control is required to prevent initial melting.

• Aging Treatment: A two-step aging process is employed. First, holding at 980-1100℃ (e.g., 5 hours) precipitates coarse γ' phases and improves carbide morphology; then, holding at 850-900℃ for an extended period (e.g., 20 hours) precipitates fine γ' phases, achieving peak strengthening and obtaining an optimal combination of strength and creep life.

| Product name | Nickel Alloy Bar/Rod |

| Diameter | 5---600mm |

| Service | Cutting (laser cutting, plasma cutting, cutting machine), forged produce |

| Standard | ASTM, AISI, DIN, EN, GB, JIS |

| Inspection | ISO,BV,SGS,MTC |

| Treatment process | Nickel electroplating, heat treatment, chemical treatment, alloying, etc |

| Mainly Grade | MARM200 MARM247 MARM246ETC. ASTM Grade: Incoloy 800 / 800H ,Incoloy 825,Inconel 600 , Inconel 625 , Inconel690,Hastelloy B , Hastelloy B-2 , Hastelloy C276 , Hastelloy C4, Hastelloy C2000, ASME Grade: N08800 N08810 N08825 N06600 N06601 N06690 N10001 N10665 N10276 N06455 N06625 EN 1.4588 2.4858 2.4817 2.4642 2.4617 2.4819 2.461 2.4856 |

| Application | Widely used in petroleum,foodstuff,chemical industry,construction, electric power,Aerospace,nuclear,energy,machinery,biotechnology,paper making,shipbuilding,boiler fields. |

| Shipment Time | Within 7-15 workdays after receiving deposit(According to the pro forma invoice) . |

| Export Packing | Standard export packing or according to the customers' request |

MarM247 superalloy is primarily used in the following areas:

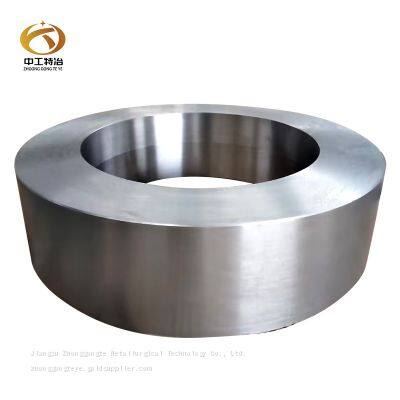

Equiaxed Crystal Casting: Due to its unique equiaxed crystal structure, MarM247 nickel-based superalloy is widely used in the manufacture of equiaxed crystal castings.

Aero-engine Components: This alloy is mainly used to manufacture hot-end components of aero-engines, such as moving and stationary blades, which operate at temperatures around 1000℃. These components operate under high temperature and high stress environments, placing extremely stringent requirements on material performance, which MarM247 effectively meets.

Heavy-Duty Gas Turbine Components: Similarly, MarM247 is suitable for manufacturing similar components for heavy-duty gas turbines, ensuring efficient operation and reliability.

Furthermore, the successful application of MarM247 nickel-based superalloy has not only improved the operating efficiency of engines and gas turbines, extended their service life, and reduced maintenance costs, but also promoted advancements in materials science and related technologies, providing strong support for the continued development of the aerospace and energy industries.

Send Inquiry to This Supplier

You May Also Like

-

China Manufacturer Inconel 617 Bar N06617 Round Steel Plate Inconel Bar Price Per KgNegotiableMOQ: 1 Ton

-

N08020 Alloy Bar High Temperature Nickel-based Alloy Spectrum Adequate StockNegotiableMOQ: 1 Ton

-

Gh3128 Nickel Base Special Steel Alloy Round BarNegotiableMOQ: 1 Ton

-

Factory Price Inconel 625 Nickel Based Alloy Inconel Rod Price Per KgNegotiableMOQ: 1 Ton

-

Factory Direct Selling Customized Size Nickel Based Alloy Tube Inconel 625NegotiableMOQ: 1 Ton

-

Inconel 625 High Temperature Nickel Alloy Bar RodNegotiableMOQ: 1 Ton

-

High Tensile Round Bar Super Alloy Inconel 625NegotiableMOQ: 1 Ton

-

Inconel 718 High Temperature Nickel-based Alloy Rods and Plates GH4169 GH2132 GH5188 China SupplierNegotiableMOQ: 1 Ton

-

GH4169 Round Steel Solid Solution Aging Inconel 718 Nickel-Based High Temperature Alloy Forging Ring CustomizationNegotiableMOQ: 1 Ton

-

Good Weldability Nickel Based Alloys 625 UNS N06625 Customized DimensionsNegotiableMOQ: 1 Ton