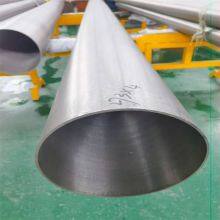

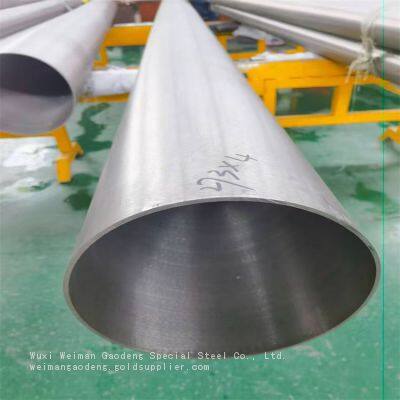

Marine Application Titanium Alloy Tube TA9 With Excellent Saltwater Corrosion Resistance

Engineered for the harshest marine environments, our Titanium Alloy Tube TA9 delivers unmatched saltwater corrosion resistance where traditional materials fail. Manufactured by Wuxi Weiman Gaodeng Special Steel Co., Ltd. with specialized expertise in titanium alloys, these tubes provide critical longevity for offshore and marine applications. With over 5 years of metallurgical precision, we supply globally through major Chinese ports to ensure timely delivery.

Key performance advantages include:

- Superior crevice corrosion resistance in seawater temperatures up to 300°F (149°C)

- 30-50% lighter than comparable stainless steel solutions

- Palladium-enhanced alloy composition prevents pitting in chloride-rich environments

- Zero biofouling characteristics for marine ecosystems

Technical specifications can be customized to project requirements. Standard mechanical properties include:

| Property | Value Range |

|---|---|

| Tensile Strength | 240-550 MPa |

| Yield Strength (0.2% offset) | 170-485 MPa |

| Elongation | 15-30% |

| Hardness (HV) | 130-220 |

| Max Operating Temp | 600°F (316°C) |

Manufacturing advantages at our 3,000m² facility include argon-protected welding and ultrasonic testing capabilities. Our production process ensures:

- Chemical composition control within ASTM B338 standards

- Surface roughness Ra ≤ 0.8μm for polished tubes

- Straightness tolerance of 1mm per meter length

- Hydrostatic pressure testing up to 1.5x working pressure

With annual exports exceeding $5 million to global marine industries, our titanium tubes have proven performance in desalination plants, shipboard heat exchangers, and offshore drilling systems. The TA9 alloy's unique Ti-0.2Pd composition provides cost-efficient longevity with maintenance intervals extended by 3-5x versus copper-nickel alternatives.

Contact our engineering team today for project-specific solutions. With direct shipments from Shanghai/Ningbo ports and custom fabrication services, we ensure your marine systems achieve maximum operational lifespan. Request material certifications and test reports to validate performance claims for your critical applications.

FAQs

Q: How does TA9 compare to grade 2 titanium in seawater?

A: TA9 contains 0.2% palladium addition that significantly improves crevice corrosion resistance, particularly in stagnant seawater conditions where grade 2 might fail.

Q: What diameters and wall thicknesses are available?

A: We produce tubes from 6mm to 250mm OD with walls from 0.5mm to 15mm. Submit your dimensional requirements for quotation.

Q: Can you supply bent or welded assemblies?

A: Yes, our facility offers cold bending (min. 3D bend radius) and orbital welding services per ASME B31.3 standards.

Q: What's the lead time for custom orders?

A: Standard sizes ship in 15-30 days. Custom metallurgical requirements may require 45-60 days production time.

Q: How do you prevent contamination during manufacturing?

A: We maintain separate production lines for titanium alloys and implement strict cleaning protocols to prevent iron contamination.

Q: What documentation accompanies shipments?

A> All shipments include material test reports with chemical analysis and mechanical properties. Mill certificates available upon request.

Q: Do you offer anti-fouling treatments?

A: Special surface treatments to reduce marine growth adhesion can be applied as an optional service.

Send Inquiry to This Supplier

You May Also Like

-

Titanium Grade 1 Plate - ASTM B265 Certified, Mill Finish, Custom Cut to SizeNegotiableMOQ: 10 Kilograms

-

Titanium Grade 2 Plate - Annealed Condition, ISO 9001:2015 Certified, Ready to ShipNegotiableMOQ: 10 Kilograms

-

Titanium Grade 5 Plate (Ti-6Al-4V) - High Strength, Aerospace Grade, CNC Machining AvailableNegotiableMOQ: 10 Kilograms

-

Titanium Grade 7 Plate (Ti-Pd Alloy) - Corrosion Resistant, Medical-Grade, Polished SurfaceNegotiableMOQ: 10 Kilograms

-

Titanium Grade 12 Plate (Ti-0.3Mo-0.8Ni) - Excellent Weldability, Industrial Grade, Mill Test CertificatesNegotiableMOQ: 10 Kilograms

-

Industry Used Gr5 Titanium Rod 8mm 10mm 30mm 40mm Tc4 Titanium Alloy Bar Grade 5 Titanium Rod Ti6al4VNegotiableMOQ: 1 Ton

-

High Quality Wholesale Titanium Tube Tc2 Titanium Alloy RodNegotiableMOQ: 1 Ton

-

Premium Heat-Resistant Gr5 Tc4 Titanium Rod for Industrial UseNegotiableMOQ: 1 Ton

-

ASTM F136 Ti-6ai-4V Tc4 Price of 1kg Round/Square Titanium Alloy Bar / Rod China ManufacturersNegotiableMOQ: 1 Ton

-

Titanium Rod ASTM B348 F136 Gr4 Gr2 Gr5 Ta2 Tc4 Seamless Customized Titanium Rod for Industrial Medical Equipment AviationNegotiableMOQ: 1 Ton