Smart Food Packing Machine With IoT Integration for Real-Time Monitoring and Control

Introducing the Smart Food Packing Machine with IoT Integration, engineered to revolutionize your packaging operations by enabling seamless real-time monitoring and control from anywhere. This cutting-edge solution reduces waste and downtime, ensuring optimal efficiency in food production lines while maintaining stringent safety standards. With its advanced IoT capabilities, you gain instant access to data analytics for proactive maintenance and cost savings. Designed for global markets, it supports high-volume packaging demands with precision and reliability, backed by Goldsupplier Tests Store's expertise as a trusted manufacturer since 2020.

Experience unparalleled control over your packaging processes, minimizing human error and maximizing throughput through intelligent automation and remote management features. This machine integrates effortlessly into existing setups, offering scalable solutions that adapt to diverse food types and production scales. Embrace the future of food packaging with a device that not only enhances operational transparency but also ensures compliance with international standards for quality and safety.

Key features include customizable settings for various food products, user-friendly interfaces, and robust construction that withstands harsh industrial environments. The IoT integration allows for cloud-based data logging, alert systems for anomalies, and remote adjustments, making it ideal for businesses aiming to boost productivity and reduce costs. As a manufacturer with an overseas office and extensive export experience, we provide tailored support to meet your specific needs in markets like North America and beyond.

- Advanced IoT Capabilities: Connect via cloud platforms for live data streaming, enabling predictive maintenance and reducing unplanned downtime by up to 30%.

- Real-Time Monitoring: Track packaging speed, weight accuracy, and temperature controls instantly through mobile or desktop apps, ensuring consistent quality.

- Customizable Controls: Adjust settings for different food types (e.g., solids, liquids) with easy-to-use touchscreens, optimizing for versatility and efficiency.

- Safety and Compliance: Built with food-grade stainless steel and certified to HACCP and SA8000 standards, it meets rigorous hygiene and ethical requirements.

- Energy Efficiency: Low-power consumption design reduces operational costs, with automated shutdown features to conserve energy during idle periods.

- Scalable Integration: Compatible with existing production lines, offering modular upgrades for increased capacity or additional IoT sensors as needed.

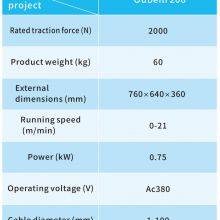

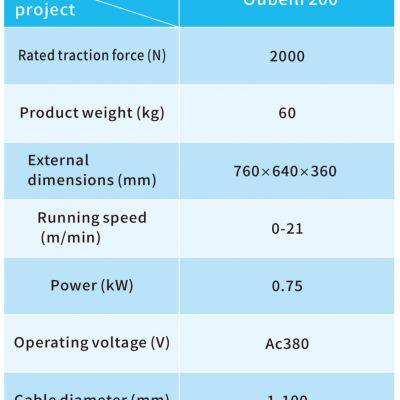

Technical specifications are detailed in the table below, highlighting core parameters to help you assess compatibility with your facility. Note that dimensions and capacities are customizable based on client requirements, ensuring a perfect fit for your operations.

| Parameter | Value |

| Power Supply | Standard 220V/380V (customizable) |

| Operating Speed | Up to 120 packs per minute |

| Weight Accuracy | ±0.5 grams |

| Temperature Range | Ambient to 50°C |

| Connectivity | Wi-Fi, Ethernet, Bluetooth |

| Material Compatibility | Plastic, foil, biodegradable films |

The advantages of this machine translate directly into tangible benefits for your business: reduced labor costs through automation, enhanced traceability for regulatory compliance, and improved product consistency that builds brand reputation. By leveraging IoT, you can monitor production in real-time from remote locations, allowing for quick responses to issues and data-driven decision-making. This not only boosts output but also minimizes risks of contamination or recalls, making it a smart investment for food processors aiming to scale sustainably.

In conclusion, this Smart Food Packing Machine offers a competitive edge with its innovative IoT integration, delivering reliability and efficiency that drive long-term savings and growth. With Goldsupplier Tests Store's global reach and commitment to quality, you benefit from responsive support and customizable solutions tailored to your market needs. Don't miss the opportunity to upgrade your packaging line—contact us today for a consultation or request a demo to see how this machine can transform your operations. Invest in a smarter future where real-time control empowers your business to thrive in dynamic markets.

For further assistance, our overseas office ensures prompt service, and with annual exports valued between US$1 Million and US$1.5 Million, we have the experience to handle your requirements efficiently. Reach out to explore how this technology can be integrated into your facility for immediate improvements in productivity and safety.

Frequently Asked Questions (FAQ)

- Q: How does the IoT integration work for real-time monitoring? A: The machine connects to cloud-based platforms via sensors, allowing users to access live data on parameters like speed and temperature through apps, enabling remote adjustments and alerts.

- Q: What certifications ensure the machine's safety for food packaging? A: It holds HACCP and SA8000 certifications, confirming adherence to food safety and social accountability standards without additional unverified claims.

- Q: Can this machine handle different types of food products? A: Yes, it is customizable for various foods, including solids and liquids, with adjustable settings available upon request to suit specific packaging needs.

- Q: What are the main markets where this product is available? A: Main markets include North America, South America, Africa, and Oceania, with shipment from Tianjin port for efficient global delivery.

- Q: How is technical support provided for international buyers? A: Support is offered through our overseas office, with remote diagnostics and on-site assistance options to ensure minimal downtime.

- Q: What is the typical delivery time for this machine? A: Delivery timelines vary based on customization but are generally within standard lead times, with details provided during order inquiries.

- Q: Does the machine require special training for operation? A: User-friendly interfaces simplify operation, and training materials are included; optional on-site training can be arranged.

- Q: Can the IoT features be upgraded in the future? A: Yes, the modular design allows for scalable upgrades, such as adding new sensors or software, to adapt to evolving technology needs.

Send Inquiry to This Supplier

You May Also Like

-

Self-Priming Centrifugal Water Pump With 100m Head 30L/s FlowUS$ 10000MOQ: 1000 Tons

-

Automatic Pressure Control Water Pump for Irrigation SystemsUS$ 10000MOQ: 1000 Tons

-

Hygienic Food Packing Machine Specifically for Dairy and Beverage Industry UseNegotiableMOQ: 1 Acre

-

Compact Food Packing Machine Featuring 500kg Capacity Ideal for Small BusinessesNegotiableMOQ: 1 Acre

-

Eco-Friendly Food Packing Machine Using Biodegradable Materials to Support SustainabilityNegotiableMOQ: 1 Acre

-

Heavy-Duty Food Packing Machine Built for Long-Term Durability in High-Volume OperationsNegotiableMOQ: 1 Acre

-

Industrial Food Packing Machine Designed for Meat and Poultry Processing FacilitiesNegotiableMOQ: 1 Acre

-

High-Capacity Cable Conveyor With Adjustable Length Options for Mining and Construction SitesNegotiableMOQ: 1 Acre

-

Heavy-Duty Bridge Tractor With 30KN Tractive Force for Long-Distance Cable Pulling in Mountainous AreasUS$ 2500.00MOQ: 1 Acre

-

Energy-Efficient FOOD PACKING MACHINE Featuring Advanced Sealing Technology and Low Power ConsumptionUS$ 222MOQ: 1 Acre