Precision-Cut DT4C Cold Rolled Coil Slitting for Reduced Material Waste and Cost Savings

Category: Pure Iron / Industrial Pure Iron / Electromagnetic Pure Iron

Place of Origin: Taiyuan, Shanxi, China

Brand/Manufacturer: TISCO (Taiyuan Iron & Steel Co., Ltd.)

Grade: DT4C

Custom Grades Available: DT4, DT4A, DT4E, YT0, YT01, YTnc1

Specification (Diameter): Thickness: 0.5 --2.0 mm

Available Diameters: 0.5, 0.8, 1.0, 1.2, 1.5, 1.8, 2.0 mm

Executive Standard: GB/T 6983-2008(PRC)

Delivery Condition: Electrical Pure Iron Cold Rolled Coil, Bright Annealed and Trimmed

Tolerance: According to GB/T 708(PRC)

Surface Quality: According to GB/T 13237(PRC)

Inspection & Rule for Re-inspection: According to GB/T 247(PRC)

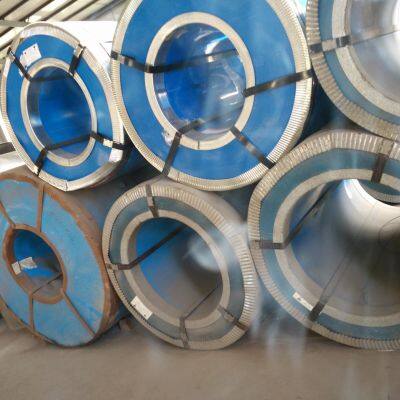

Packaging: The cold coil is wrapped with steel sheet and securely fastened with steel strapping.

Bundle Weight: Approx. 10000 kg

Subsequent Processing: Cut-to-Length、Slitting、Stamping、Bending

Physical Properties:

• Density: 7.85 g/cm³

• Hardness (HV5): 85 - 140

• Tensile Strength (Rₘ): 176 - 274 MPa

• Reduction of Area (Z): 70% - 80%

• Yield Strength (RₑL): 0.298 - 166 MPa

• Impact Toughness (KV): 160 - 200 J/cm²

• Elongation after Fracture (A): 30% - 50%

• Bend:180°OK

Magnetic Properties:

Coercivity (Hc): ≤ 32 A/m

Maximum Permeability (μₘ): 0.0151 H/m

Magnetic Induction: Please refer to the Magnetic Properties Table.

GB/T 6983-2008 Magnetic Properties Table

Chemical Composition:

Standard Requirements

C≤0.010、Si≤0.100、Mn≤0.250、P≤0.0150、S≤0.010、

Al0.2~0.8、Ti≤0.020、Cr≤0.10、Ni≤0.050、Cu≤0.050

Chemical Composition: Typical / Actual Reference

C≤0.0011、Si≤0.005、Mn≤0.12、P≤0.010、S≤0.006、

Al 0.460、Ti<0.010、Cr<0.010、Ni 0.010、Cu<0.01

Key Characteristics:

(1)、Excellent Electromagnetic Properties: Low coercivity (Hc), high permeability (μ), high saturation magnetic flux density (Bs), stable magnetism, and no magnetic aging.

(2)、High Purity: The electromagnetic pure iron series are fully killed steels and undergo refining processes, resulting in a dense, uniform, and superior internal structure with low gas content. The typical carbon content in the finished product is<0.004%, which provides reliable conditions for users to simplify and shorten the part annealing process.

(3)、Good Cold and Hot Workability:

Cold working such as turning, upsetting, punching, bending, and drawing can be performed without issues.

Hot working, such as re-forging or re-rolling, shows low sensitivity to red shortness. Many grades have no red-shortness range, allowing processing within a wide temperature window.

(4)、Good Surface Quality: Exhibits excellent weldability and plating performance.

(5)、High Dimensional Accuracy: Can supply ultra-precision cold-rolled sheets. For sheet thickness ≤1.5mm, the thickness tolerance can be guaranteed within ≤±0.03mm; for thickness >1.5mm, the tolerance is within ≤±0.05mm.

Applications:

Electromagnetic pure iron is primarily used in the electrical, telecommunications, instrumentation, and advanced defense industries to manufacture electromagnetic components and iron cores.

1. Relay Cores, Armatures, and Yokes in electrical and telecommunications systems: For relays in automatic telephones, railway signal relays, and various purpose relays (e.g., thermal, pulse, time-delay, special type) used in communication and automatic control systems, as well as relays for electrical control equipment.

2. Core Material for Electromagnets: Iron cores for bending and focusing magnets in high-energy accelerators, acoustic devices, solenoid valves, and electromagnets for magnetic separation equipment.

3. Soft Magnetic Components for Instruments and Meters: High-resolution pole pieces for analytical instruments, electromagnetic separators and detectors in geological instruments, focusing magnets for electron microscopes and electromagnetic lenses for scanning electron microscopes, aircraft automatic control components, and pole pieces for magnetizers.

4. Cores and Housings for DC Motors: Such as those used in aviation DC motors.

5. Electrical and Magnetic Parts for Automobiles, Tractors, and Machine Tools: Including automotive voltage regulators, flashers, starters, horns, electromagnetic chucks for machine tools, magnetic plates, and other magnetic conduits.

6. Magnetic Shielding Equipment: Various magnetic shielding casings or boxes, and shielding materials for applications requiring high shielding effectiveness.

Ordering Instructions:

(1) Select the correct grade: Grades DT3 and DT3A do not guarantee freedom from magnetic aging. For guaranteed non-aging properties, order DT4 (A, E, C). Magnetic performance levels are Standard, Advanced (A), Extra High (E), and Super (C). For higher magnetic performance, specify higher grades (E, C).

(2) Guaranteed properties: The electromagnetic pure iron series generally guarantees electromagnetic performance; chemical composition is not the acceptance criterion unless specified by the customer in the contract.

(3) Magnetic annealing: The electromagnetic properties of our products are measured on test samples after magnetic annealing. However, products are delivered in hot-rolled, hot-forged, or softened annealed (for cold-rolled/cold-drawn material) conditions. Therefore, to fully realize the material's magnetic potential, parts must undergo magnetic annealing after manufacturing.

* Simplified Annealing Process (if carbon content ≤ 0.007%): 850°C for 3 hours.

* Standard Annealing Process (if carbon content > 0.007%): Follow the process specified by the Chinese National Standard (GB).

(4) Standard magnetic tests: Typically, only coercivity (Hc) and post-aging coercivity are routinely tested. If guarantees for magnetic induction (B) or maximum permeability (μm) are required, please specify this in the contract.

(5) High-precision cold-rolled material: For extra-thickness precision in cold-rolled materials, please order Super Precision Cold-Rolled Sheet according to standard YB(T) 34-86.

(6) Custom specifications: For requirements exceeding current GB or YB(T) standards, we can negotiate and establish a separate technical agreement for supply.

(7) Delivery time: For standard, non-processed goods, the delivery period is typically 1-2 working days. For goods requiring additional processing, the delivery time will be determined based on the complexity of the drawings.

(8) For more pure iron technical data, information, market trends, and knowledge, or to request a quote, please contact us.

(9) Information accuracy disclaimer: Due to the vast amount of online information, prices and delivery terms listed on websites may not always be current. We appreciate your understanding. Please contact us directly for accurate, up-to-date information. All details are subject to final confirmation upon inquiry.

Send Inquiry to This Supplier

You May Also Like

-

Industrial Pure Iron Coil for Magnetic Shielding Equipment, Superior Shielding EffectivenessNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Coil Bright Annealed, Tolerance Compliant With GB/T 708 StandardNegotiableMOQ: 1 Ton

-

Customizable Grades DT4, DT4A, DT4E Pure Iron Coil for Versatile Electromagnetic ComponentsNegotiableMOQ: 1 Ton

-

Pure Iron Coil DT4C Cold Rolled Coil for Automotive Electrical Parts: Regulators, Starters, and HornsNegotiableMOQ: 1 Ton

-

Industrial Pure Iron Coil Stock With Surface Quality Meeting GB/T 13237 for Welding and PlatingNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Coil DT4C Cold Coil Density 7.85 G/cm³, Tensile Strength 176-274MPaNegotiableMOQ: 1 Ton

-

Cold Rolled Pure Iron For Instrumentation: High-Resolution Pole Pieces Material, Pure Iron DT4C Cold Rolled CoilNegotiableMOQ: 1 Ton

-

Industrial Pure Iron Cold Rolled Coil Easy Processing Pure Iron Coil Ideal for Subsequent Cutting, Slitting, and BendingNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Coil Stock Pure Iron Cold Rolled Coil With High Saturation Flux for Electromagnetic Chucks in Machine ToolsNegotiableMOQ: 1 Ton

-

Electrical Pure Iron Coil Stock Compliant With GB/T 6983-2008 Standard, Pure Iron Coil for Broad Electrical ApplicationsNegotiableMOQ: 1 Ton