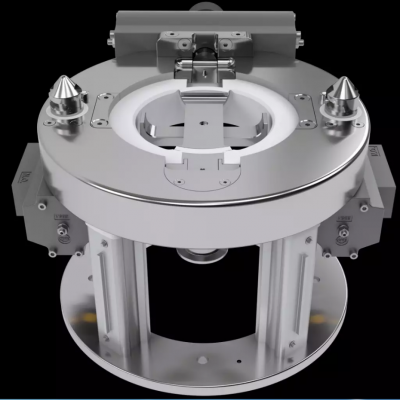

Alphadock WIP/CIP Active Wash Valve Pneumatic OEB5 Split Butterfly Valve Pharma Machinery

email: qya@alpha-bj.com

whatsapp: +86 15900996444

AWZ

Active wash valve with Activeflange

WIP device with spray nozzle and drain port

Pneumatic Actuators, aluminium housing

Main and disc seal in FPM/EPDM white/black, FDA

Contact parts in SS1.4404/316L

Sensor Switches

Lifting Modular

Bellow in PE white

After pharmaceutical production, it is a must to wash the valve in containment. That's why we'll need the wash valve. The active wash valve is for washing the passive valve together with the IBC containers. The passive wash valve is for washing the active valve together with the equipment. There will be coustomized solutions for your washing needs.

Alphadock Split Butterfly Valve, also known as High Containment Valve, Composed of active and passive valves, is used for material sealing, sterile transportation, avoiding cross contamination, and effectively protecting operators and the operating environment. Suitable for loading, unloading, batching, crushing, sampling, etc. under isolated conditions.

During the docking loading and unloading process, the active valve and passive valve are connected as a whole. Once open the butterfly valve, the docking and distribution of materials are carried out; After the material distribution is completed, the butterfly valve is closed. Loosen the fastening handle, the active and passive valves can be separated, and each equipment can be sealed and transported separately to ensure isolation.

Alphadock split butterfly valve can reach OEB5 level, and relevant documents can be provided to meet the needs of high-end customers at home and abroad.

Internationally trusted by Roche, Novartis, Copenhagen Atomics Aps, Fette Compacting, Harro Höfliger, Envair, GEA, and more, here's how our solutions can optimize your modular solid dosage workflows:

1. Leakage limit OEL<1µg/m ³ (OEB5-compliant), adding a vacuum cleaner can lower the value;

2. Proven mature technology, with a maximum allowance of ± 14mm for docking;

3.180 ° symmetrical design, flexible docking position;

4. Modular design of material contact components, easy to replace;

5. Customized, integrated, and highly automated to meet high-end needs.

Size series:

DN50/100/150/200/250/300

Send Inquiry to This Supplier

You May Also Like

-

Alphadock WIP/CIP Active Wash Valve Pneumatic OEB5 Split Butterfly Valve Pharma MachineryNegotiableMOQ: 1 Unit

-

Alphadock Oeb5 Split Butterfly Valve Active Valve Pneumatic Pharma Machinery Containment OSD ProcessNegotiableMOQ: 1 Unit

-

Alphadock Oeb5 Split Butterfly Valve Active Valve Pneumatic Pharma Machinery Containment OSD ProcessNegotiableMOQ: 1 Unit

-

Alphadock WIP/CIP Active Wash Valve Manual OEB5 Split Butterfly Valve Pharma Machinery ContainmentNegotiableMOQ: 1 Unit

-

Alphadock WIP/CIP Passive Wash Valve Manual OEB5 Split Butterfly Valve Pharma Machinery ContainmentNegotiableMOQ: 1 Unit

-

Alphadock Oeb5 Split Butterfly Valve Active Valve Pneumatic Pharma Machinery Containment OSD ProcessNegotiableMOQ: 1 Unit

-

Alphadock Oeb5 Split Butterfly Valve Active Valve Pneumatic Pharma Machinery Containment OSD ProcessNegotiableMOQ: 1 Unit

-

Alphadock Oeb5 Split Butterfly Valve Manual Pharma Machinery Containment OSD ProcessNegotiableMOQ: 1 Unit

-

Alphadock Oeb5 Split Butterfly Valve Active Valve Manual Pharmaceutical Machinery OSDNegotiableMOQ: 1 Unit

-

Alphadock OEB5 Split Butterfly Valve Passive Valve Pharma Machinery Containment Powder OSD ProcessNegotiableMOQ: 1 Unit