Customized Anti-Corrosion Seamless Welded Titanium Coil Tube Twisted Tube Titanium Spiral Coil Tube Supplier

Customized Anti - Corrosion Seamless Welded Titanium Coil Tube: A Superior Solution for Global Industries

1. Product Overview

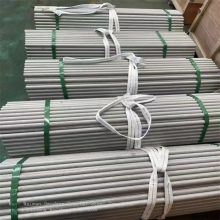

Our customized anti - corrosion seamless welded titanium coil tube, also known as the twisted tube or titanium spiral coil tube, is a revolutionary product designed to meet the diverse needs of various industries worldwide. Crafted from high - quality titanium, this tube offers exceptional performance and durability.

The tube comes in a unique spiral or twisted shape, which not only enhances its aesthetic appeal but also provides several functional advantages. Its seamless welded construction ensures a continuous and smooth inner surface, reducing the risk of fluid leakage and minimizing pressure drop during operation.

2. Material Advantages

- Titanium Composition: The tube is made of titanium, a material renowned for its outstanding corrosion resistance. Titanium can withstand harsh chemical environments, including acids, alkalis, and saltwater, making it an ideal choice for applications in the chemical, marine, and oil and gas industries.

- Lightweight yet Strong: Titanium has a high strength - to - weight ratio. This means that the tube is lightweight, which simplifies installation and reduces transportation costs. At the same time, it can withstand high pressures and mechanical stresses, ensuring long - term reliability in demanding applications.

- Biocompatibility: In addition to its industrial uses, titanium's biocompatibility makes it suitable for medical applications. Our titanium coil tubes can be used in medical devices where corrosion resistance and non - toxicity are crucial.

3. Customization Options

- Shape and Size: We understand that different industries have different requirements. That's why we offer a wide range of customization options for the shape and size of the coil tube. Whether you need a specific diameter, length, or pitch for the spiral, our experienced engineers can work with you to create a tube that perfectly fits your needs.

- Surface Finish: The surface finish of the tube can also be customized. We can provide a smooth finish for applications where minimizing friction is important, or a textured finish for better adhesion in certain processes.

- Special Coatings: For even greater corrosion resistance or specific functional requirements, we can apply special coatings to the tube. These coatings can further enhance the tube's performance in extreme environments.

4. Manufacturing Process

- Seamless Welding Technology: Our state - of - the - art seamless welding technology ensures that the tube has a uniform and strong weld. This process eliminates the weak points that are often associated with traditional welded joints, improving the overall integrity of the tube.

- Precision Manufacturing: We use advanced manufacturing equipment and techniques to ensure the precision of the tube's shape and dimensions. Every tube is carefully inspected during the manufacturing process to meet the strictest quality standards.

- Quality Control: Our quality control team conducts comprehensive tests on each tube, including non - destructive testing (NDT) methods such as ultrasonic testing (UT) to detect any internal defects. This ensures that only high - quality tubes are delivered to our customers.

5. Applications

- Chemical Industry: In chemical processing plants, our anti - corrosion titanium coil tubes are used for heat exchangers, condensers, and reactors. They can handle corrosive chemicals without degradation, ensuring the safety and efficiency of the production process.

- Marine Industry: For marine applications, such as desalination plants and shipboard systems, the tubes' resistance to saltwater corrosion is invaluable. They can be used in cooling systems, seawater intake pipes, and other components exposed to the harsh marine environment.

- Medical Industry: In the medical field, these tubes can be used in medical equipment such as dialysis machines and surgical instruments. Their biocompatibility and corrosion resistance make them a safe and reliable choice for medical applications.

- Oil and Gas Industry: In oil refineries and offshore platforms, our titanium coil tubes can be used in pipelines, separators, and other equipment. They can withstand the corrosive effects of oil, gas, and associated chemicals, reducing maintenance costs and improving operational efficiency.

6. Company Background

We are Wuxi Weiman Gaodeng Special Steel Co., Ltd., a leading manufacturer in the special steel industry since 2017. Our company has a strong R & D focus and has evolved from a research - based startup to a global special steel solution provider. We have a team of experts, including a CEO with over 20 years of experience in the special steel industry and a chief metallurgist with a PhD from Tsinghua University. Our technical staff consists of ASME - certified NDT Level III inspectors and NADCAP - qualified engineers, ensuring the highest quality of our products. We have established strategic partnerships with international organizations such as SGS and BV for third - party audits and with German DMV Mannesmann and Spanish Tubacex for premium alloy sourcing. Our company is also committed to sustainability, with 95% of our waste being recycled.

With an annual export share of US$5 Million - US$10 Million, we serve major markets around the world, including North America, South America, Europe, Asia, Africa, and Oceania. Our products comply with international standards such as ASTM, EN, JIS, and API, ensuring that they meet the requirements of global customers.

In conclusion, our customized anti - corrosion seamless welded titanium coil tube is a high - quality product that offers excellent performance, durability, and customization options. Whether you are in the chemical, marine, medical, or oil and gas industry, our tube can provide a reliable solution for your needs.

Send Inquiry to This Supplier

You May Also Like

-

TA10 Titanium Alloy Tube for Chemical Piping Spot Stock Chinese Manufacturer Compatible With Pressure Vessel SystemsNegotiableMOQ: 100 Kilograms

-

Gr7/TA9 Titanium Welded Tube for Power Plant Machinery Reliable Production Factory Suitable for High Pressure Industrial UseNegotiableMOQ: 100 Kilograms

-

Gr1 Titanium Seamless Tube for Mechanical Processing Chinese Factory Direct Supply Ideal for Precision MachiningNegotiableMOQ: 100 Kilograms

-

Gr2 Titanium Alloy Welded Tube for Industrial Equipment Strong China Factory Perfect for Light Mechanical ManufacturingNegotiableMOQ: 100 Kilograms

-

Ti-6Al-4V/Gr5 Titanium Seamless Tube for Chemical Machinery Spot Stock Manufacturer Suitable for Pressure Vessel ApplicationsNegotiableMOQ: 100 Kilograms

-

TC4 Titanium Welded Tube for Power Plant Equipment Chinese Production Factory Compatible With Industrial Piping SystemsNegotiableMOQ: 100 Kilograms

-

TA18/Gr9 Titanium Alloy Tube for Environmental Machinery Strong China Factory Ideal for Green Protection EquipmentNegotiableMOQ: 100 Kilograms

-

Gr12 Titanium Welded Tube for Chemical Equipment Reliable Chinese Manufacturer Suitable for Corrosive Industrial EnvironmentsNegotiableMOQ: 100 Kilograms

-

TA9/Gr7 Titanium Seamless Tube for Mechanical Manufacturing Spot Stock Factory Perfect for Industrial UseNegotiableMOQ: 100 Kilograms

-

Gr1 Pure Titanium Tube for Decorative and Light Industrial Use Chinese Production Factory Compatible With Custom SizesNegotiableMOQ: 100 Kilograms