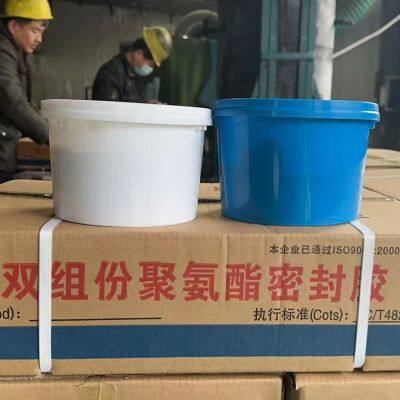

Application Scenarios of Two-Component Polysulfide Sealant

Two-component polysulfide sealant is a high-performance elastic sealing material consisting of a base paste and a curing agent. Its core advantages—excellent

water resistance, weatherability, chemical corrosion resistance, and long-term elasticity (maintaining flexibility for decades)—make it a go-to solution for sealing needs across construction, hydraulic engineering, transportation, and industrial sectors. Below is a detailed breakdown of its key application scenarios, highlighting how its properties align with specific industry requirements.

1. Construction Engineering: Sealing for Building Envelopes & Wet Areas

In construction, this sealant is primarily used to seal joints exposed to outdoor elements or frequent moisture, preventing water infiltration and extending structural lifespan.

1.1 Curtain Wall Sealing

Application Areas: Gaps between glass panels and aluminum frames, joints between adjacent aluminum profiles, and connections between curtain walls and building exterior walls (common in high-rise offices, shopping malls, and luxury residential buildings).

Why It Works:

Strong adhesion to glass, aluminum, and concrete, ensuring no detachment under temperature fluctuations (-40°C to 80°C).

Superior UV and weather resistance, avoiding cracking, hardening, or discoloration from long-term sun and rain exposure.

Practical Example: In coastal skyscrapers (e.g., Dubai Marina, Shanghai Lujiazui), it resists salt spray corrosion and heavy rainfall, maintaining a leak-proof seal for over 20 years—outperforming ordinary silicone sealants.

1.2 Door & Window Sealing

Application Areas: Joints between door/window frames and building walls, gaps between glass panes and sashes (critical for waterproof doors/windows in basements, bathrooms, and exterior walls).

Why It Works:

No shrinkage or cracking after curing, unlike traditional acrylic sealants—preventing water seepage in wet areas (e.g., bathroom windows) or regions with extreme temperature changes.

Compatibility with diverse materials: adheres well to wood, PVC, aluminum, and masonry.

1.3 Roof & Exterior Wall Sealing

2. Hydraulic Engineering: Sealing for Water-Immersed Structures

Hydraulic projects demand sealants that withstand long-term water immersion and resist corrosion from water impurities—properties that two-component polysulfide sealant excels at.

2.1 Dam & Sluice Sealing

Application Areas: Expansion joints and construction joints of concrete dams, sluice gates, and water-retaining walls; gaps between sluice gate frames and concrete foundations.

Why It Works:

Excellent water resistance: no water absorption or swelling during long-term immersion, preventing internal structural corrosion.

Resistance to fresh water, sewage, and weak alkaline water, avoiding degradation from impurities in water.

Elasticity absorbs slight deformation caused by water pressure or temperature changes.

Practical Example: In rural medium-sized concrete dams (e.g., those in the U.S. Midwest or Chinese rural areas), it replaces traditional asphalt sealants, reducing maintenance frequency from once every 3–5 years to once every 15–20 years.

2.2 Water Pipeline & Tank Sealing

Application Areas: Flange connections of buried/underwater water supply pipelines, joints of concrete water storage tanks, and gaps between tank liners (e.g., fiberglass liners) and steel/concrete walls.

Why It Works:

Forms a dense, flexible seal that withstands slight pipeline vibration or ground settlement—preventing leaks in critical water supply infrastructure.

Resists corrosion from residual chlorine in tap water or organic matter in sewage, ensuring drinking water safety.

3. Transportation Engineering: Sealing for Vibration & Weather-Exposed Infrastructure

Transportation assets (bridges, tunnels, highways) face constant vibration, temperature shifts, and environmental erosion—two-component polysulfide sealant provides durable sealing to protect structural integrity.

3.1 Bridge Sealing

3.2 Tunnel Sealing

3.3 Highway & Railway Sealing

Application Areas: Expansion joints of highway pavements (especially in regions with large temperature differences), gaps between railway track slabs and concrete bases, and joints of highway guardrail foundations.

Why It Works:

Withstands repeated rolling from vehicles/trains without crushing or detachment.

Maintains stability in extreme temperatures: no hardening in cold weather or softening in heat (up to 80°C), ensuring consistent sealing performance.

4. Industrial Equipment: Sealing for Chemical & Special Environments

In industrial settings, this sealant is used for equipment exposed to chemicals, oil, or extreme temperatures—leveraging its chemical resistance and thermal stability.

4.1 Chemical Storage Tank Sealing

Application Areas: Flange connections of tanks storing weak acids, alkalis, or organic solvents (e.g., ammonia water, dilute sulfuric acid), manhole joints, and gaps between tank liners and steel shells.

Why It Works:

Resists corrosion from most non-strong corrosive chemicals, avoiding dissolution or degradation that causes leaks.

Forms a tight seal that prevents toxic chemical leakage, protecting workers and the environment.

4.2 Industrial Pipeline Sealing

Application Areas: Joints of pipelines transporting cooling water, lubricating oil, or low-concentration chemical solutions; gaps between pipelines and equipment interfaces (e.g., pumps, valves).

Why It Works:

Adheres well to steel, cast iron, and plastic pipelines, accommodating slight expansion or vibration from industrial operations.

Oil and grease resistance ensures no degradation in mechanical equipment lubrication systems.

4.3 Electrical Equipment Sealing

Summary

Two-component polysulfide sealant’s unique combination of durability, water resistance, and elasticity makes it indispensable in scenarios requiring long-term, reliable sealing. From high-rise curtain walls to hydraulic dams, and from highway bridges to industrial chemical tanks, it solves critical sealing challenges and extends the service life of structures and equipment. Its compatibility with diverse materials further broadens its application across industries.