Nylon Coated Buckles Used Nylon Powder Coating for Durable Underwear Accessories

Introduction to Nylon Powder Coated Underwear Buckles Underwear accessories are often overlooked, but buckles are a critical part of ensuring a secure fit and long product life. For years, the intimate apparel industry relied on liquid epoxy coatings for underwear buckles— a solution that quickly proved inadequate. Epoxy coatings peel after minimal washing, can’t handle temperature changes, and often irritate the skin. Today, nylon powder coating has revolutionized the industry, offering a durable, user-friendly alternative that meets the evolving needs of brands and consumers.

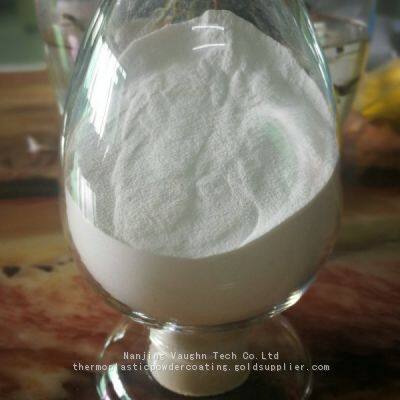

Our nylon powder-coated underwear buckles are the result of advanced coating technology and mature domestic manufacturing processes. Designed specifically for the intimate apparel sector, these buckles prioritize both performance and comfort. The iron base is coated with high-quality nylon powder (model 78-1008), creating a product that is strong, flexible, and compatible with the demands of daily use. Whether for mass-market underwear lines or high-end luxury brands, these buckles deliver consistent quality and functionality.

The exceptional performance of our nylon coated buckles is largely due to the unique, mature coating process— a step above traditional spraying methods.

The process begins with heating small iron buckle workpieces in a tunnel furnace to a high temperature. Next, the heated buckles are moved to a closed fluidized vibration disk, where they evenly pick up nylon powder. Since the small workpieces have low heat capacity, they can’t melt the surface powder on their own— so a second heating step is added to ensure the powder melts and flows smoothly, forming a uniform coating.

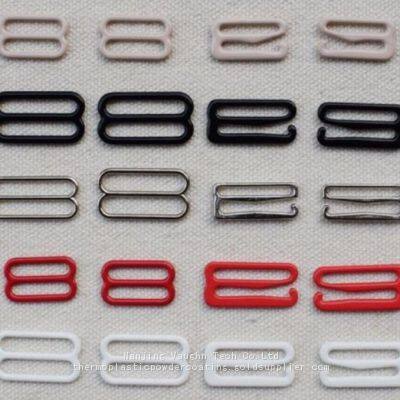

The biggest advantage of this vibration disk process is that it creates a no-hanging-point surface. Unlike other processes that leave uneven, raised spots (hanging points) on the coating, the vibration of the disk ensures the powder adheres evenly, resulting in a smooth, flawless finish. This not only improves the buckle’s appearance but also prevents skin irritation from rough edges.

Additionally, the process is highly efficient. Domestic equipment can produce up to 1 million buckles per shift per machine— a rate that meets the high-volume needs of large underwear manufacturers. This efficiency also helps keep costs competitive, making high-quality nylon coated buckles accessible to brands of all sizes.

Product and Material SpecificationsThe following table outlines the key specifications of our nylon coated buckles and the nylon powder used in the coating process:

Specification Category | Details |

Buckle Specifications | Product Type: Nylon Coated Iron Buckles for Underwear; Standard Colors: White, Black; Surface: Smooth, no hanging points; Compatibility: Underwear, sports bras, shapewear |

Nylon Powder Details | Model: 78-1008; Particle Size: 30μm - 70μm; Properties: Easy to level, non-sticky, high whiteness, high gloss; Dye Type: Water-soluble acid dyes, disperse dyes |

Coating Performance | Wear Resistance: Withstands washing machine rubbing; Temperature Resistance: Dryer temperature-resistant; Water Resistance: Resistant to cold/hot water cycles; Hygiene: Antibacterial, non-irritating to skin |

Production Details | Manufacturing Process: Tunnel furnace heating + vibration disk powdering + secondary heating; Production Capacity: 1,000,000 pieces/shift/machine; Quality Control: Strict defect inspection (no uneven coating) |

Benefits for Underwear Manufacturers and Consumers

Benefits for Underwear Manufacturers and ConsumersOur nylon coated buckles create a win-win situation for both underwear manufacturers and the end consumers who use the products.

For manufacturers, the benefits start with production efficiency. The high output rate of 1 million pieces per shift means large orders can be fulfilled quickly, avoiding delays in underwear production lines. The flexible coloring option (white buckles dyeable to any color) also simplifies inventory management— instead of stocking dozens of buckle colors, manufacturers can keep a small stock of white and black buckles and dye them as needed. This reduces storage costs and minimizes waste from unsold colored buckles.

The durable coating also reduces quality control issues. Unlike epoxy-coated buckles that fail testing for wear or water resistance, our nylon-coated buckles consistently pass industry standards, lowering the rate of defective products and returns.

For consumers, the advantages are even more direct. The wear-resistant coating ensures the underwear lasts longer— no more replacing bras or underwear just because the buckle coating peeled off. The skin-friendly, antibacterial surface is gentle on sensitive skin, preventing rashes or irritation. The ability to match buckle colors to fabric also means underwear looks more cohesive and polished, enhancing the overall user experience.

Why Nylon Powder Coating Beats Traditional EpoxyThe shift from liquid epoxy to nylon powder coating is not just a trend— it’s a necessary upgrade driven by performance and consumer demand. Here’s why nylon powder coating is superior:

• Durability: Epoxy coatings peel after 5-10 washes, while nylon powder coatings last 50+ washes without damage. This longevity is a key selling point for value-conscious consumers.

• Resistance to Environmental Factors: Epoxy deforms in hot water or dryer heat, but nylon remains stable. This makes nylon-coated buckles more practical for everyday use.

• Hygiene: Epoxy is porous and can trap bacteria, but nylon’s non-porous surface resists bacterial growth— a critical feature for products in contact with sensitive skin.

• Aesthetics: Epoxy coatings often have uneven finishes or hanging points, while nylon’s vibration disk process creates a smooth, flawless surface. The flexible coloring also allows for better design coordination.

Our high-efficiency process nylon coated buckles are a game-changer for the underwear industry. With their durable coating, advanced manufacturing, and benefits for both brands and consumers, they set a new standard for underwear accessories. Whether you’re a large manufacturer or a boutique brand, these buckles will elevate the quality and appeal of your products.

Send Inquiry to This Supplier

You May Also Like

-

Bra Steel Ring End Coating Nylon PA11 PA12 Powder Coating BULE White ColorUS$ 10 - 30MOQ: 100 Kilograms

-

High Adhesion Nylon PA11/PA12 Powder Coating for Bra Underwires – Weather-Resistant & Skin-Safe ProtectionUS$ 10 - 30MOQ: 100 Kilograms

-

Low Temperature Flexible Nylon Powder Coating (PA11/PA12) for Bra Underwires – Long-Lasting & Chemical-FreeUS$ 10 - 30MOQ: 100 Kilograms

-

Nylon PA11/PA12 Bra Underwire Coating UV Resistant & Laundry Durable Powder FinishUS$ 10 - 30MOQ: 100 Kilograms

-

Efficient Nylon Powder Coating for Bra Underwires (PA11/PA12) – Consistent Quality & Cost-Effective ProductionUS$ 10 - 30MOQ: 100 Kilograms

-

Impact-Resistant Nylon PA11/PA12 Powder Coating for Dishwasher Baskets - Stain-Proof, Easy-to-Clean Black Coating With 8-10 Year LifespanUS$ 10 - 30MOQ: 100 Kilograms

-

Nylon PA11/PA12 Powder Coating for Dishwasher Baskets - High-Toughness Black Coating for Metal BasketsUS$ 10 - 30MOQ: 100 Kilograms

-

Flexible Nylon PA11/PA12 Powder Coating for Dishwasher Baskets - Easy-to-Clean, High-Adhesion Black Coating With 8-10 Year LifespanUS$ 10 - 30MOQ: 100 Kilograms

-

Skin-Friendly & Durable Nylon Powder Coating for Underwear Accessories - 50+ Washes Resistance, Antibacterial Buckle CoatingUS$ 10 - 30MOQ: 100 Kilograms

-

Nylon Powder Coating for Underwear Buckles - Dyeable, Temperature-Resistant & High-Gloss CoatingUS$ 10 - 30MOQ: 100 Kilograms