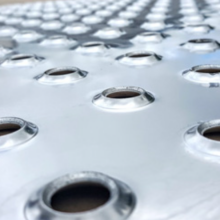

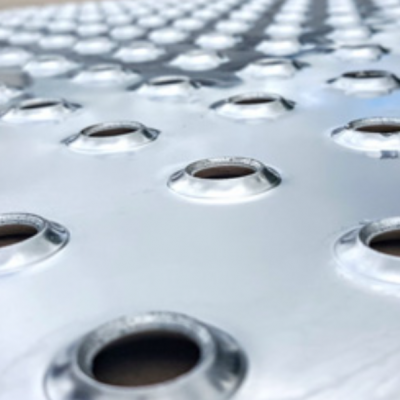

Manufacturing sectors for filtration and ventilation purposes, yet more and more it is being spec’d by interior designers and architects as a material for many residential and commercial construction projects. Its reflective qualities, variety of opening patterns and the durability it delivers make perforated metal an excellent choice for uniquely interesting surface

Round

Round holes are the most popular and widely used patterns in many applications across a broad industry range, from HVAC and filtration systems to acoustic panels and agricultural equipment. With their simple shape, round patterns provide maximized open areas and increased strength-to-weight ratios.

Round patterns also offer better structural integrity compared to other shapes. The circular shape distributes stress evenly

across the perforated metal, minimizing the risk of deformation or failure under pressure. This feature makes round perforations ideal for applications where strength and durability are crucial.

In addition, round perforations provide increased visibility through the perforated metal. The circular shape allows more light to pass through the panel, making it practical for applications requiring transparency or aesthetic appeal. Round patterns are also among the most efficient to produce and, in most cases, the least expensive hole shape.

Square

Square patterns are highly versatile because of the many different nesting possibilities. This feature is especially beneficial for applications requiring increased drainage or airflow. Like round holes, square shapes can provide excellent strength and stability depending on the chosen pattern.

The straight edges of square perforations allow for easy alignment with other components, so they are ideal for equipment with assembled components, like grills or guards on machinery or appliances. Square patterns also resist impact loads and block trespassers when spaced appropriately.

Hexagonal

Hexagon patterns can pack together tighter to produce more open area than many round or square configurations. Hexagonal

perforations allow air, light or sound to pass through the panel. They are perfect for applications where ventilation or

transparency are crucial.

Depending on the layout, hexagonal shapes can distribute stress evenly across a panel, making it resistant to deformation while

providing strength and stability for applications like grating or ceiling panels. Additionally, hexagonal patterns offer an

aesthetically pleasing appearance with a higher open-area percentage when airflow is critical.

Slotted

Slotted holes feature elongated and rectangular patterns that produce a sleek appearance while allowing optimal airflow. These

linear openings work well in various configurations for applications that have specific functionality requirements, including

filtration, drainage systems and ventilation. Slotted patterns are highly beneficial for directional sorting and the grating of

solid objects.

The elongated nature of slotted holes allows for a larger open area, enabling maximum passage of light, sound or air. This feature

makes slotted holes desirable for applications requiring high transparency levels or optimal acoustic performance.we can tailor

the slot length and width to specific requirements and patterns for highly precise or specialized applications.

Diamond

Diamond patterns stand out over other shapes for their unique aesthetic. The repeated diamond geometries create a visually

appealing pattern that makes them highly popular for architectural designs or decorative purposes. The diamond-shaped perforations

also balance openness and coverage to deliver the required airflow levels, light transmission or visibility.

Ellipse

An ellipse's elongated and curved geometry creates unique patterns, making these configurations desirable for applications that

prioritize aesthetics, like architectural facades or decorative panels. An ellipse's oval shape also allows for specific levels of

airflow, light transmission or visibility, offering a combination of openness, transparency and coverage. This benefit makes

ellipse patterns ideal for applications requiring a balance between functionality and visual appeal.

Additionally, ellipse patterns offer versatility in terms of customization. The ellipse size, orientation and spacing can be

adjusted to meet specific requirements, allowing for tailored solutions for different applications

Designer

Designer or ornamental patterns can create a unique and customized look for a specific product or application. These intricate and

artistic designs add a touch of elegance and sophistication to the perforated metal panel, making them ideal for projects where

aesthetics are critical, including architectural features, high-end furniture and interior design components.

Specialized designer patterns can offer unique functional benefits. Depending on the application's requirements and functionality,

these panel patterns can be tailored to optimize airflow, light diffusion or acoustics. This capability ensures the perforated

metal looks visually appealing and performs optimally in its intended function.

Acoustical cabinets: Perforated metal is excellent for sound attenuation and sound absorption. You can use perforated metal to create acoustic material protection or decorative noise control system covers. Materials scatter, reflect or absorb sound waves as they travel through perforated metal.

Appliances: Perforated metal supports proper appliance operations. With the right perforation holes and designs, you can

adequately filter debris, maintain equipment temperature and prevent moisture buildup.

Architecture: Perforated metal enhances design, energy efficiency and functionality in architectural applications.

Filtration: offers metal perforation patterns to create durable filters that pass liquid or air effectively.

Food and beverage: Food and beverage applications require perforated metal that is functional, safe and aesthetically pleasing. offers PVC-protected and polished perforated metal with clean components

Agricultural equipment: The agricultural industry relies on quality perforated metal for equipment such as grinders, harvesters and tractors. offers perforated patterns and services to help you create quality hoods, grilles, access panels and grain screens.

Medical: The medical industry relies on perforated metal for components such as perforated trays, biomedical glove box diffusers, fume hoods, clean room diffusers and animal caging. offers metal perforation services and products that meet strict requirements where air flow is critical.

Perforation Size |

0.5mm up to 154mm Perforations

|

Metal Types & Grades

|

Mild Steel, Pre-Galvanised Steel, Stainless Steel, Aluminum, Brass and Coppers. Other Materials are available on request.

|

Sheet Thickness

| 0.75mm thick up to 12mm thick, 20mm thick material is available on request. |

Sheet Sizes

| 1m x 2m/1.25m x 2m/1.5m x 3m/4m x 2m on Request |

% Open Area | All Open Area possible standard tooling provides from 20% up to 60%. Popular open area tends to be between 30% – 50% |

Send Inquiry to This Supplier

You May Also Like

-

Manufacturer's HB240 Ladder Mesh 4\" Width X 10FT Length Standard Weight Stainless Steel Wire for Masonry Bending WeldingUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

Wholesale 9GA Galvanized Truss Mesh 8\" Width X 10FT Brick Force Mesh Stainless Steel Wire Welded Bending for Wall StabilityUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

Heavy-Duty 3/16\" Brick Force Stainless Steel Truss Mesh 200mm Width Factory Price for Industrial Use Bending Welding AvailableUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

SS 304 Truss Mesh 6\" Width Anti-Crack Brick Force Welded Mesh for Residential Commercial Buildings Cut Welded Available AlibabaUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

316 Stainless Steel Wire Truss Mesh Corrosion-Resistant Force Mesh for Retaining Walls Factory Bending ServiceUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

8\" Width Galvanized 3-Wire Truss Mesh Stainless Steel Structural Reinforcement Mesh for Composite Walls Welding Bending OfferedUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

304 Stainless Steel Ladder Mesh 3.75mm Wire Diameter 6\" Width X 10FT Length Welded for Wall Reinforcement Custom Cutting forUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

Heavy-Duty Ladder Mesh 3/16" Stainless Steel Wire 150mm Width Mansory Mesh Price for High-Rise ConstructionUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

Custom Lengths Anti-Crack Steel Ladder Mesh 8\" Width Stainless Steel Wire Welded Bending Mansory Mesh Factory Sales forUS$ 0.50 - 0.95MOQ: 5000 Pieces

-

9GA Galvanized 4\" Width Stainless Steel Wire Ladder Mesh 2-Wire Reinforcement for Boundary Walls-Factory Bending WeldingUS$ 0.50 - 0.95MOQ: 5000 Pieces