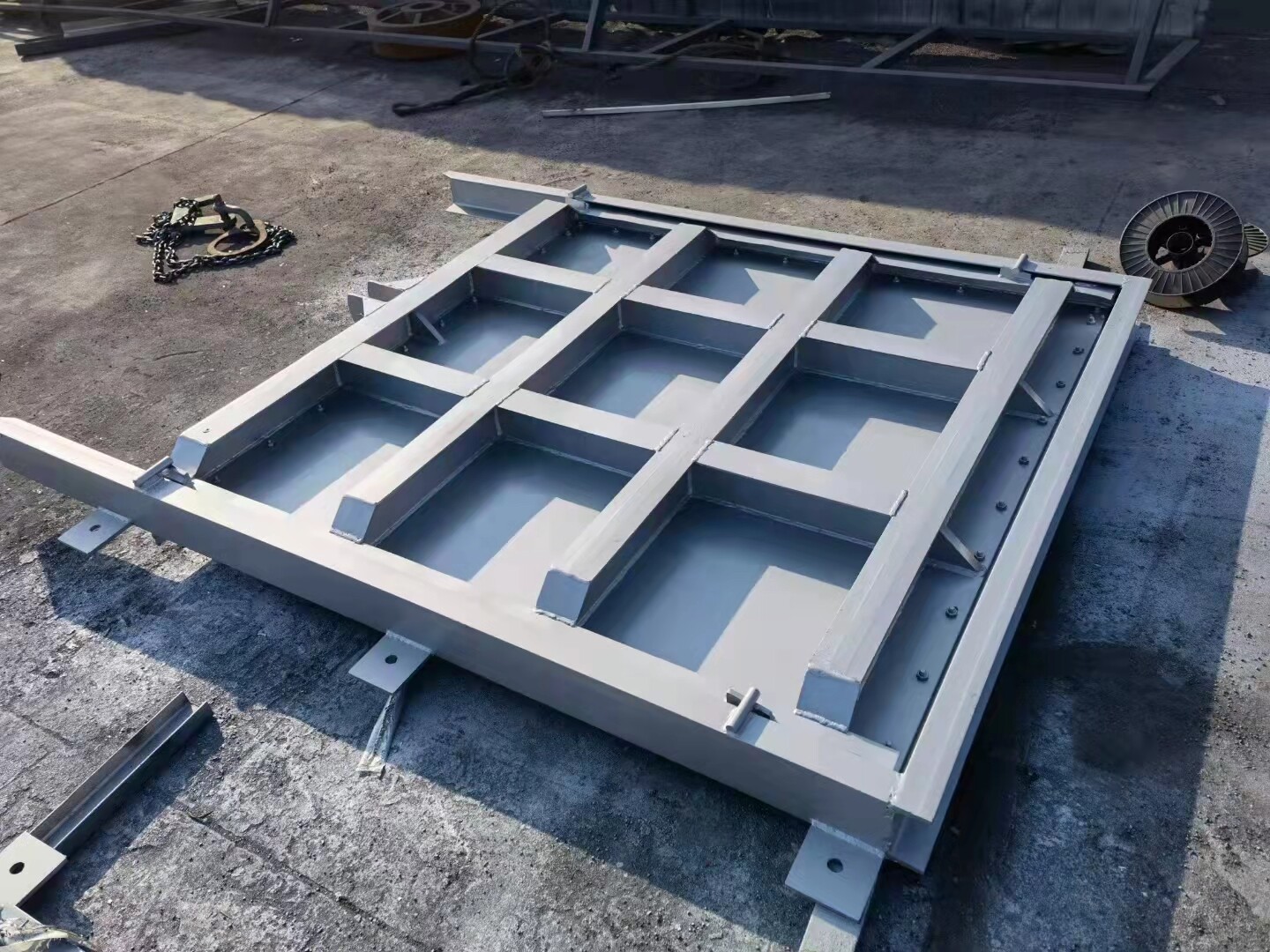

Arc Gate Sewage Treatment Hydropower Station Overflow Dam Discharge Steel Gate Reservoir Hydraulic Arc Gate

Advantages of Radial Gates

1. Optimal Structural Stress Distribution

2. Excellent Hydraulic Performance

3. Low Operating Force and Energy Efficiency

4. Easy Maintenance and Accessibility

5. Versatility in Large-Span and High-Head Applications

6. Reliable Sealing Performance

Send Inquiry to This Supplier

You May Also Like

-

Steel Sluice Gate, Hydraulic Curved Steel Sluice Gate Manufacturer, Reservoir Switch, Power Station Stainless Steel Sluice ValveUS$ 1000 - 1150MOQ: 1 Combo

-

Steel Sluice Gate Channel, Steel Electric Sluice Gate, Curved Hydraulic Steel Gate, Manufacturer, Reservoir Stainless Steel Regulating Weir GateUS$ 1000 - 1150MOQ: 1 Combo

-

Cast Iron Sluice Gate, Curved Cast Iron Sluice Gate, Source Manufacturer for Hydraulic Engineering Construction, Available in Various SpecificationsUS$ 1000 - 1150MOQ: 1 Combo

-

Hydraulic Lifting Steel Dam Gate Factory Curved Stainless Steel and Carbon Steel Dam Flat Sliding Fixed Wheel Flap Floodgate ReservoirUS$ 1000 - 1150MOQ: 1 Combo

-

Arc-shaped Sluice Gate Engineering Channel Gate Machine Cast Iron Reservoir Steel Integrated Manual Water-stopping Square Solid FactoryUS$ 1000 - 1150MOQ: 1 Combo

-

Planar Sliding Fixed-wheel Arched Steel Sluice Gate for Hydraulic Engineering Channels and River Steel GatesUS$ 1000 - 1150MOQ: 1 Combo

-

Arc-shaped Steel Sluice Gate Channel for Water Conservancy and Farmland Regulation, Bidirectional Watertight Shut-off and DrainageUS$ 1000 - 1150MOQ: 1 Combo

-

Manufacturer Supplies Steel Sluice Gates, Curved Hydraulic Steel Winch Sluice Gates, Reservoir Hydraulic Facilities, Steel Sluice GatesUS$ 1000 - 1150MOQ: 1 Combo

-

Arc-shaped Gate River Steel Gate, Planar Steel Gate, Hydraulic Engineering Channel River GateUS$ 450 - 452MOQ: 1 Combo

-

Arc-shaped Steel Sluice Gate, Reservoir, Hydropower Station, Inspection Hole, Top Discharge, Flood Discharge, SpillwayUS$ 450 - 452MOQ: 1 Combo