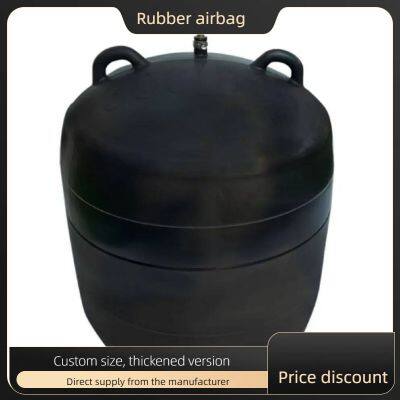

Pipeline Plugging Airbag is Made of Reinforced Natural Rubber

Pipeline Plugging Airbag: A Convenient Tool for Temporary Blockage

I. Basic Concept and Core Structure1. Core Functions

2. Main Structure

II. Working Principle

III. Common Types (Classified by Application/Pipeline Type)

IV. Usage Precautions (Key Points to Avoid Problems)

Send Inquiry to This Supplier

You May Also Like

-

Flexible Inflatable Rubber Airbag for Sewer and Drainage Pipe Blocking,Simple OperationUS$ 12 - 16MOQ: 10 Combos

-

Spot Inflatable Pipeline Plugging Airbag Sewer Pipe Drainage Plugging Leak Closed Water Test Plugging Water Plugging AirbagUS$ 12 - 16MOQ: 10 Combos

-

High Pressure Good Tightness Pipeline Block Airbag With High QualityUS$ 12 - 16MOQ: 10 Combos

-

Inflatable Sealing Airbag Rubber Sewer Pipe Plug Balloon Stopper Inflatable Pipe Stopper Pipeline Plugging AirbagUS$ 12 - 16MOQ: 10 Combos

-

Inflatable Rubber Pipeline Blocking Airbag for Pipeline Solution at HomeUS$ 12 - 16MOQ: 10 Combos

-

Inflatable High Pressure Pipeline Plugging Rubber AirbagsUS$ 12 - 16MOQ: 10 Combos

-

DN1500 Inflatable High Pressure Pipeline Plugging Rubber AirbagsUS$ 12 - 16MOQ: 10 Combos

-

High-Quality Inflatable Water Stop Blockage Airbag for Pipeline Sealing and Leak PreventionUS$ 12 - 16MOQ: 10 Combos

-

Pneumatic Inflatable Sewer Drain Pipeline Stopper Rubber Airbag Pipe PlugUS$ 12 - 16MOQ: 10 Combos

-

New 2024 Product High Pressure Pipeline Blocking Rubber Airbag/balloon for Sewer Line 0.1~1.5 MPAUS$ 12 - 16MOQ: 10 Combos