Boeing-Certified GR5 Titanium Forgings ASTM B348 for Aircraft Landing Gear Systems

Titanium Bar Product Details 1. Product Overview

We are a professional titanium bar manufacturer, providing factory-direct supply of a full range of industrial-grade and medical-grade titanium bars & titanium alloy bars. Our product portfolio covers pure titanium (GR1/TA1, GR2/TA2), high-strength alloys (GR5/TC4, GR23/TC4 ELI), and special corrosion-resistant alloys (GR7/TA9, GR9/TA10). All products strictly comply with international standards such as ASTM, ISO, and ASME. We offer customization of dimensions, processes, and surface treatments to meet B2B procurement needs across industries including aerospace, medical, chemical engineering, and new energy.

2. Core Product Series1. Industrial Pure Titanium Series (GR1/TA1, GR2/TA2)

• Material Features: Excellent corrosion resistance, good ductility, suitable for normal and medium-low temperature working conditions; density 4.51g/cm³, compliant with ASTM B348 standard.

• Common Specifications: Diameter 10-300mm, length 2-6m (customizable), tolerance H6-H9; optional surface treatments include pickling (ASTM B861), grinding, and mill finish.

• Core Applications: Chemical equipment (chlor-alkali, desulfurization), marine engineering (submarine hulls, offshore platforms), water treatment (desalination equipment), and general mechanical parts.

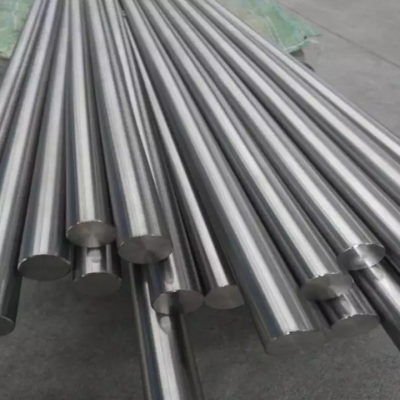

2. High-Strength Titanium Alloy Series (GR5/TC4, GR23/TC4 ELI)

• Material Features: Composed of Ti-6Al-4V, with tensile strength ≥895MPa and elongation ≥10%; GR23/TC4 ELI offers excellent biocompatibility and no cytotoxicity.

• Certifications: Aerospace-grade products comply with ASTM B348/AMS 4928; medical-grade products comply with ASTM F136/FDA certification and meet CE/PED requirements.

• Core Applications: Aerospace (aircraft engines, landing gear, spacecraft fuel tanks), medical implants (hip/knee replacements, dental implants), and high-end manufacturing (semiconductor equipment, 3D printing feedstock).

3. Special Functional Alloy Series (GR7/TA9, GR9/TA10, GR12)

• GR7/TA9 (Ti-0.15Pd): Resistant to chloride ion corrosion, suitable for chemical chloride environments and seawater desalination equipment;

• GR10/TA10 (Ti-0.3Mo-0.8Ni): Seawater corrosion resistance, used in marine ships (propellers, hull components) and offshore oil & gas equipment;

• GR12: High-temperature resistance (≤400℃), applicable to nuclear reactors, geothermal energy systems, and high-temperature fluid transport pipelines.

3. Key Technical Parameters & Processes

Item | Parameter Range | Executive Standard |

Diameter Specification | 10-300mm (round bar/hexagonal bar/flat bar) | ASTM B348 |

Length | 2-6m (cuttable on demand) | Custom Requirements |

Tolerance Grade | h6-h9 (precision grade), h10-h11 (standard grade) | ISO 8015 |

Manufacturing Process | Hot forging/cold rolling/extrusion, annealing, centerless grinding | ASME SB-348 |

Surface Treatment | Pickling, polishing (H8/H9 mirror finish), sandblasting, anodizing | ASTM B861 |

Core Performance (GR5/TC4) | Tensile strength ≥895MPa, Yield strength ≥825MPa | ASTM B348 Class 2 |

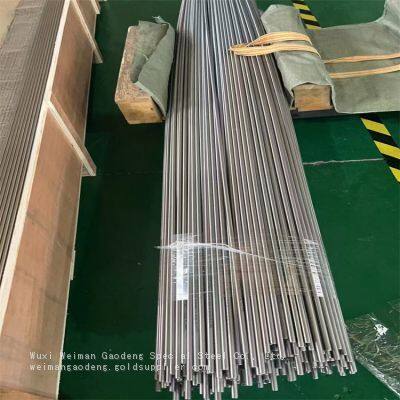

4. Industry-Specific Custom Solutions1. Aerospace Industry

• Products: GR5/TC4 titanium bars (ASTM B348/AMS 4928), GR9 titanium alloy tubes, compatible with Boeing/Dassault certifications;

• Services: Provide material mechanical property test reports, batch traceability, and meet aerospace-grade quality control requirements.

2. Medical Implant Industry

• Products: GR23/TC4 ELI titanium bars (ASTM F136), GR4 surgical titanium bars (ISO 5832-3), with FDA/RoHS certifications;

• Services: Customized cutting and polishing, provide biocompatibility test reports, and adapt to orthopedic/dental implant processing.

3. Chemical & New Energy Industry

• Products: GR2/TA2 pure titanium bars (acid/alkali resistant), GR10/TA10 titanium bars (seawater resistant), GR5 titanium bipolar plates;

• Applications: Chlor-alkali chemical equipment, PEM electrolyzers (hydrogen energy), 70MPa hydrogen storage tanks; support bulk procurement and long-term supply.

4. High-End Manufacturing Industry

• Products: Precision GR5 titanium bars (tolerance h6) for semiconductor equipment, GR5 feedstock for 3D printing (DED);

• Customization: Non-standard dimensions (e.g., special-shaped bars, ultra-thin flat bars), and pre-processing services to match customers’ machining needs.

5. B2B Trade Services & Guarantees

1. Supply Model: Factory-direct supply, supporting wholesale, customization, spot goods (3-5 days delivery for standard specifications), and futures (15-20 days lead time for customized specifications);

2. Logistics Terms: Support FOB Shanghai/Shenzhen, CIF Hamburg/Jeddah/Ho Chi Minh City, etc.; cooperate with international logistics providers (DHL, Maersk) to ensure cargo timeliness;

3. Certification Guarantee: All products pass ISO 9001:2015 quality system certification; medical-grade products add FDA/CE; aerospace-grade products add AMS certification;

4. After-Sales Support: Provide factory quality inspection reports (including composition and mechanical properties); return/replacement available if quality does not meet standards; long-term cooperative customers enjoy price discounts.

6. Cooperation Advantages

• Source Factory: No middlemen markup, high cost-effectiveness; annual production capacity of 1,000+ tons, capable of undertaking large orders;

• Customization Capability: Full-process customization from dimensions, processes to surface treatments, adapting to customers’ personalized production needs;

• Industry Experience: 10+ years of titanium bar export experience, serving buyers in 30+ countries across Europe, America, the Middle East, and Southeast Asia, familiar with local import standards.

For sample testing, bulk quotations, or customized solutions, please contact us directly for one-on-one B2B procurement consulting services!

Send Inquiry to This Supplier

You May Also Like

-

Hot-Forged TC11 Titanium Bar High-Temperature Resistant for Jet Engines & TurbinesNegotiableMOQ: 100 Kilograms

-

Indonesia Marine Titanium Rod TA5/TA17 for Ship Propellers & Offshore StructuresNegotiableMOQ: 100 Kilograms

-

TIMET GR5 Alternative Titanium Bar Factory Direct Price for Cost-Saving B2B OrdersNegotiableMOQ: 100 Kilograms

-

Mill Finish GR2 Titanium Bar for Canadian Industrial Machinery Importers Fast DeliveryNegotiableMOQ: 100 Kilograms

-

Titanium Bar for 3D Printing DED Grade 5 Feedstock ASTM B348 Additive ManufacturingNegotiableMOQ: 100 Kilograms

-

Arctic-Resistant GR2 Titanium Rod for Polar Oil & Gas Exploration EquipmentNegotiableMOQ: 100 Kilograms

-

Malaysia GR2 Titanium Bar Supplier for Water Treatment & Chemical Processing PlantsNegotiableMOQ: 100 Kilograms

-

High-Tensile TC4 Bar (≥895MPa) ASTM B348 for Spacecraft Fuel Tanks & SatellitesNegotiableMOQ: 100 Kilograms

-

Powder Bed Fusion Titanium Alloy Bar GR5 for Advanced Additive Manufacturing ApplicationsNegotiableMOQ: 100 Kilograms

-

Titanium Rod Supplier GR5 Distributor for Aerospace & Defense ContractorsNegotiableMOQ: 100 Kilograms