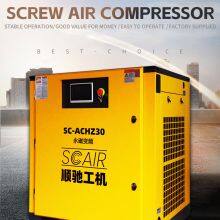

7.5KW 10HP 0.8MPa Screw Air Compressor - Oil-Free PM VSD for CNC & Manufacturing | SCAIR

Product Overview

The SCAIR SC-ACBS10 series permanent magnet variable frequency screw air compressor is engineered for demanding industrial applications. Featuring a rare-earth permanent magnet motor (IE4 efficiency, 94.5%) and coaxial direct-drive technology, it eliminates belt transmission losses. With a power rating of 7.5KW (10HP), it delivers 1.0m³/min FAD at 0.8MPa. Through variable frequency control (0–300Hz), it dynamically matches air output to demand, achieving over 30% energy savings compared to fixed-speed models (verified annual savings of ¥120,000+ in automotive CNC production lines). The IP65-rated fully sealed enclosure provides dust and water resistance, making it ideal for high-contamination environments like mining and spray painting. Noise levels are maintained at ≤65dB(A) at 1-meter distance, 13dB below industry standards.

Free Air Delivery (F.A.D): 1.0m³/min @ 0.8MPa (compliant with ASTM D1257)

Cooling Method: Air-cooled (stable operation from -5°C to 45°C)

Power Supply: 3-Phase 380V/50Hz (compatible with 440-460V/60Hz)

Oil Specification: ISO VG 32 full synthetic oil (6,000-hour change interval)

Air Purity: ≤3ppm oil carryover (ISO 8573-1 Class 0 certified)

Dimensions & Weight: 900×670×880mm / 170kg (compact design saves 30% space)

Key Advantages & Innovations

PM VSD Energy Saving Technology

Dynamically adjusts motor speed, reducing no-load energy consumption to near zero. Saves 28.5% energy at 50% load compared to fixed-speed units.

Triple Anti-Corrosion Protection

Housing passes 72-hour ASTM G48 salt spray test without corrosion, extending service life by 40% in acidic environments like electroplating shops.

Intelligent EPC Control System

Touchscreen interface supports PROFIBUS-DP communication protocol for real-time monitoring of pressure, temperature, and filter status. Fault self-diagnosis response<0.5 seconds.

Ultra-Quiet Operation

Patent-pending silencer + floating shock absorption design maintains noise ≤65dB(A), meeting EU standards for nighttime factory operations.

Target Industries & Applications

CNC Machining Centers: Stable 1.0m³/min airflow prevents tool breakage during cooling (compatible with pneumatic grinders and impact drills).

Spray Painting Lines: ≤3ppm oil content eliminates "fish eyes" in automotive paint finishes, compatible with pneumatic spray guns.

Mining Equipment: Operates continuously for 120 hours at 45°C without derating, pairs with pneumatic rock drills.

Assembly Line Pneumatic Tools: Supports multiple devices including pneumatic wrenches and nail guns with pressure fluctuation<0.02MPa.

Certifications & Warranty

International Certifications: CE, ISO 9001, GB/T 19153-2019 Grade 1 energy efficiency

Warranty Policy: 3 years on main components (industry average: 1-2 years), lifetime technical support

Maintenance Optimization: Air filter replacement at 2,500 hours, oil filter at 3,000 hours (reduce interval by 20% in dusty environments), initial oil change at 500 hours, subsequent changes every 2,500 hours

Q1: Can it retrofit existing piston compressors?

→ Yes. The SCAIR VF-Kit7.5 retrofit module enables 35% energy savings without structural modifications.

Q2: How to handle dust in quarry operations?

→ Standard nanocoated air filters with reverse-pulse cleaning extend service life to 4,000 hours.

Q3: Is 0.8MPa sufficient for 1.2m³/min tools like reciprocating saws?

→ Upgrade to SC-ACBS20 model (2.2m³/min). Maximum flow for 7.5KW unit is 1.0m³/min (e.g., pneumatic riveters).

Send Inquiry to This Supplier

You May Also Like

-

SCAIR 75HP Industrial Oil-Free Air Compressor 0.8MPa for Heavy-Duty Pneumatic NetworksNegotiableMOQ: 1 Unit

-

SCAIR 100HP Oil-Free Centurion Compressor 0.8MPa for Aerospace & Heavy Industrial Air SystemsNegotiableMOQ: 1 Unit

-

SCAIR 10HP Oil-Free Air Compressor 0.8MPa Compact for Dental Labs & Auto ShopsNegotiableMOQ: 1 Unit

-

SCAIR 20HP Oil-Free Compressor 0.8MPa for Precision Plastic Molding & Textile AutomationNegotiableMOQ: 1 Unit

-

SCAIR 30HP Oil-Free Compressor 0.8MPa for Laser Cutting & Beverage Carbonation SystemsNegotiableMOQ: 1 Unit

-

SCAIR 50HP Oil-Free Compressor 0.8MPa for Automotive Painting Robots & Precision CoatingNegotiableMOQ: 1 Unit

-

SCAIR 60HP Oil-Free Compressor 0.8MPa for Shipyard Dry-Docking & Semiconductor Dry Air SystemsNegotiableMOQ: 1 Unit

-

SCAIR 75HP Oil-Free Compressor 0.8MPa for Fracking Air Systems & Petrochemical Instrument AirNegotiableMOQ: 1 Unit

-

SCAIR 100HP Zero-Emission Oil-Free Compressor 0.8MPa for Green Hydrogen & Carbon Capture SystemsNegotiableMOQ: 1 Unit

-

SCAIR 10HP 1.0MPa Oil-Free Compressor for Laboratory Instruments & Surgical RoboticsNegotiableMOQ: 1 Unit