New Restaurant Food Equipment Biscuit Bread and Moon Cake Forming Production Line

New Restaurant Food Equipment Biscuit Bread and Moon Cake Forming Production Line

1. Overview

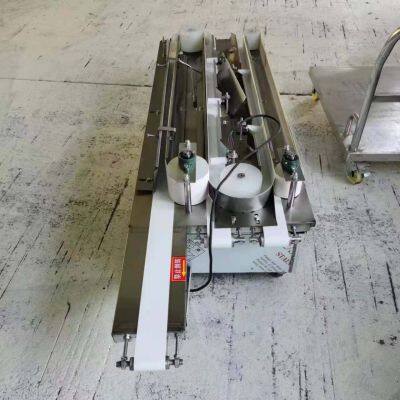

This state - of - the - art production line is a revolutionary addition to the restaurant food equipment market. Designed by Jinan Xinyuqi Food Machinery Co., Ltd., a company with years of in - depth industry experience and ISO9001 production certification, it is tailored to meet the high - volume and high - quality production needs of biscuits, bread, and moon cakes. Whether you are a small - scale local eatery or a large - scale restaurant chain, this production line will significantly enhance your food production capabilities.

2. Versatility in Application

One of the most remarkable features of this production line is its wide range of applications. It can be used for making various types of bread, from soft white bread to crusty whole - wheat loaves. For biscuits, it can produce different shapes, sizes, and flavors, such as chocolate - chip COOKIEs, butter biscuits, and savory crackers. When it comes to moon cakes, it can handle both traditional and modern fillings, like lotus seed paste, red bean paste, and even ice - cream fillings. This versatility allows restaurants to diversify their menus and attract a broader customer base.

3. High - Quality Production

The production line is built with high - quality materials and advanced manufacturing techniques. The forming mechanisms are precision - engineered to ensure consistent shapes and sizes of the products. For example, the dough sheeting and cutting parts are designed to create uniform bread slices and biscuit pieces. In the case of moon cakes, the molds are crafted to produce detailed and aesthetically pleasing patterns on the surface. This high - quality production not only improves the visual appeal of the food but also enhances its taste and texture.

4. Efficiency and Productivity

In a busy restaurant environment, time is of the essence. This production line is designed for maximum efficiency. It has a high - speed production capacity, capable of producing a large number of products in a short period. The automated processes, such as dough mixing, filling dispensing, and product forming, reduce the need for manual labor and minimize human errors. The conveyor belts and transfer systems are optimized to ensure a smooth and continuous flow of production, from the raw material stage to the final product. This results in increased productivity and reduced production costs.

5. Ease of Operation and Maintenance

The production line is user - friendly, with an intuitive control panel that allows operators to easily adjust settings such as production speed, filling quantity, and product size. Even those with limited technical knowledge can quickly learn to operate the equipment. Additionally, the design of the production line takes into account easy maintenance. The components are easily accessible, and the equipment is designed for quick disassembly and cleaning. This reduces downtime for maintenance and ensures that the production line can operate continuously for long periods.

6. Safety Features

Safety is a top priority in any food production environment. This production line is equipped with multiple safety features. There are emergency stop buttons located at convenient positions along the line, allowing operators to immediately halt the production in case of an emergency. The moving parts are protected by safety guards to prevent accidental contact. The electrical systems are designed with proper insulation and grounding to avoid electrical hazards. These safety features ensure the well - being of the operators and the smooth running of the production process.

7. After - Sales Service

Jinan Xinyuqi Food Machinery Co., Ltd. offers excellent after - sales service. With a comprehensive service team consisting of mechanical engineers, electrical automation experts, and food technologists, they can provide prompt technical support and maintenance. Whether it's a minor adjustment or a major repair, the team is ready to assist. They also offer training programs for operators to ensure they can make the most of the production line. This commitment to after - sales service gives customers peace of mind and confidence in their investment.

In conclusion, this new restaurant food equipment biscuit, bread, and moon cake forming production line is a game - changer in the food production industry. Its versatility, high - quality production, efficiency, ease of operation, safety features, and excellent after - sales service make it an ideal choice for restaurants looking to improve their food production capabilities. With this production line, you can take your restaurant's food offerings to the next level and gain a competitive edge in the market.

Send Inquiry to This Supplier

You May Also Like

-

Balls Shaping Pizza Dough Divider/Dumpling Dough Rolling Machine Grain Product Making MachineNegotiableMOQ: 1 Set

-

Round Shape Steamed Bun Forming Machine Pizza Dough Ball Rolling MachineNegotiableMOQ: 1 Set

-

Small Bread Dough Divider Rounder Dough Shaping Conveyor Dough Rolling Machine for BakeryNegotiableMOQ: 1 Set

-

Long Big French Baguette Bread Making Machine Baguette Dough Rolling Molding Machine for SaleNegotiableMOQ: 1 Set

-

Efficient Commercial Rice Steamer Works With Steaming CabinetNegotiableMOQ: 1 Set

-

Stainless Steel Seafood Steaming Rice Cabinet Ensures DurabilityNegotiableMOQ: 1 Set

-

Good Price Steaming Cabinet / Commercial Steaming Rice CabinetNegotiableMOQ: 1 Set

-

Commercial Stainless Steel Gas Rice Steaming Cabinet 12 Trays With WheelsNegotiableMOQ: 1 Set

-

Multi Layer Commercial Rice Steamer Complements Steaming CabinetNegotiableMOQ: 1 Set

-

Factory Price Food Steamer Steam Cooker Rice Steaming Cabinet With High EfficiencyNegotiableMOQ: 1 Set