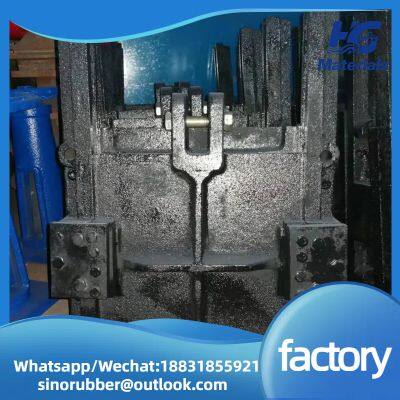

Anti-corrosion and Rust-proof Cast Iron Sluice Gate Trader, Perfect After-sales Service,, Complete Styles, Suitable for Farmland Irrigation

Cast iron sluice gates are robust, heavy-duty hydraulic control devices widely utilized in water management systems, playing a critical role in regulating water flow across various industrial, agricultural, and municipal applications.

Constructed primarily from high-grade cast iron—known for its exceptional strength, rigidity, and resistance to wear and corrosion—these gates are engineered to withstand harsh aquatic environments, including fresh water, sewage, and moderately aggressive water conditions. Their durable composition ensures longevity, even with continuous exposure to moisture, sediment, and fluctuating pressure.

A typical cast iron sluice gate comprises three core components: the gate leaf (a solid, vertically or horizontally movable panel that controls water passage), the frame (a fixed structure that guides the gate’s movement and forms a watertight seal when closed), and the operating mechanism (which may be manual, gear-driven, electric, or hydraulic, depending on the size and application). The gate leaf often features precision-machined edges to ensure a tight seal against the frame, preventing leakage when closed.

Functionally, these gates excel at regulating water levels, controlling flow rates, and isolating sections of water systems. When raised, they allow water to pass through; when lowered, they block or restrict flow, enabling operators to manage water distribution in irrigation canals, control flooding in rivers, or isolate pipelines and reservoirs for maintenance. Their robust design makes them particularly suitable for high-pressure applications, such as dam outlets or large-scale water diversion projects.

Key advantages of cast iron sluice gates include their structural stability under heavy loads, minimal maintenance requirements, and compatibility with various water types. While heavier than alternative materials like steel or composites, their weight contributes to their stability and sealing efficiency. Regular inspections—focused on lubricating moving parts, checking for corrosion, and ensuring proper alignment—help extend their service life, often spanning decades.

In summary, cast iron sluice gates are indispensable in water resource management, offering a reliable, long-lasting solution for controlling and directing water flow in critical infrastructure, from agricultural irrigation networks to urban water supply and drainage systems.

Send Inquiry to This Supplier

You May Also Like

-

Haogu Gate Factory Flat Steel Gates, Large-scale Hydraulic and Hydropower Steel Flat Gates, Customizable for HydropowerUS$ 100 - 3000MOQ: 10 Combos

-

Steel Gate, Electric Reservoir and Hydropower Plant Stainless Steel Flat Sliding Square Gate, Supports CustomizationUS$ 100 - 3000MOQ: 10 Combos

-

Steel Gate Valves With Overlapping Beams, Small Overlapping Beam Steel Gate Valves, Convenient and Flexible, CustomizableUS$ 100 - 3000MOQ: 10 Combos

-

Manufacturing Square Steel Sluice Gates for Reservoirs, River Sewage Channels, Hydraulic Machinery, Flat Stainless Steel Sluice Gate FactoryUS$ 100 - 3000MOQ: 10 Combos

-

Steel Sluice Gate Manufacturer, Flat Arched Steel Gate, Supporting Customization for Water Conservancy Projects and Sewage TreatmentUS$ 100 - 3000MOQ: 10 Combos

-

Steel Gate, Sliding Flat Steel Gate, River Channel, Reservoir Pump Station Steel, Custom ManufacturerUS$ 100 - 3000MOQ: 10 Combos

-

Steel Gate, Sliding Flat Steel, Channel Stainless Steel Gate, Reservoir Steel Gate, Herringbone-shaped Curved GateUS$ 100 - 3000MOQ: 10 Combos

-

Large-scale Hydraulic Steel Dam, Landscape Hydraulic Dam, Water-retaining Dam, Replica Steel GateUS$ 100 - 3000MOQ: 10 Combos

-

Sliding 2.0×2.0m Flat Fixed-wheel Steel Gate, Steel-composite Cast Steel Maintenance Gate, With Good PerformanceUS$ 100 - 3000MOQ: 10 Combos

-

Steel Sluice Gates for River Channels, Reservoirs, and Pump Stations; Large Water-blocking Dams With Steel Gates; Physical Factory.US$ 100 - 3000MOQ: 10 Combos