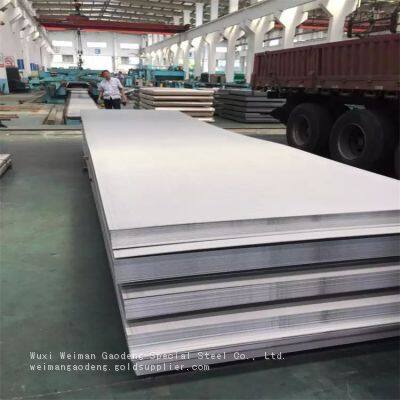

High Precision UNS N06022 N06200 Stainless Steel Plate 15mm Cold Rolled Instrument Plate

We offer high-performance stainless steel plates and nickel alloy plates covering 28 UNS grades (e.g., UNS N06455, N06022, N10276, N08825). Each product combines two complementary UNS materials, tailored for industrial durability, corrosion resistance, and precision performance. Suitable for diverse sectors like petrochemicals, marine engineering, food processing, and power generation.

1. Material Advantages

Our dual-material combinations integrate the strengths of each UNS grade to meet specific application needs:

• UNS N06455 + N06022: Exceptional resistance to aggressive chemicals (e.g., sulfuric acid, chloride solutions) and high-temperature oxidation, ideal for industrial reactors.

• UNS N10276 + N06200: Superior thermal stability (up to 1200°C) and wear resistance, perfect for furnace components and high-heat machinery.

• UNS N08800 + N08825: Excellent saltwater corrosion resistance and mechanical strength, widely used in marine equipment and offshore platforms.

• UNS N07718 + N04400: High toughness and fatigue resistance, suitable for precision engineering parts and aerospace components.

2. Selling Points in DetailThickness & Precision

• Thickness range: 0.8mm–16mm (thin gauge for instruments, thick gauge for heavy-duty structures).

• Strict dimensional tolerance (±0.05mm for cold-rolled plates) ensures compatibility with assembly requirements.

Surface Finishes

• Polished: Mirror-like surface (Ra ≤ 0.8μm) for decorative or sanitary applications (e.g., food catering equipment).

• Brushed: Matte texture (Ra 1.6–3.2μm) for scratch resistance, ideal for furniture and appliance components.

• Matte Finish: Low-reflectivity surface for industrial machinery and furnace parts.

• Smooth Finish: Uniform texture from annealing, suitable for chemical lab equipment.

Manufacturing Processes

• Cold Rolled: High precision (tight tolerance) and smooth surface, used for precision instruments and electronic components.

• Hot Rolled: High strength and wear resistance, perfect for construction, machinery, and marine structures.

• Annealed: Reduces internal stress, enhances ductility—ideal for parts requiring bending or machining.

Core Performance

• Corrosion Resistance: Withstands acids, saltwater, and industrial chemicals (critical for petrochemical and marine use).

• High-Temperature Stability: Maintains strength at 600–1200°C (suitable for power plant boilers and furnace parts).

• High Strength & Toughness: Tensile strength up to 980MPa, suitable for heavy-duty engineering and aerospace.

3. Application Fields

Our plates are engineered for sector-specific reliability:

• Petrochemical & Chemical Industry: Reactors, heat exchangers (using UNS N06455+N06022 for acid resistance).

• Marine Engineering: Boat parts, offshore platforms (UNS N08800+N08825 for saltwater corrosion resistance).

• Food & Catering Equipment: Catering counters, processing tanks (UNS N10675+N09925 for food safety and easy cleaning).

• Power Generation: Furnace components, power plant pipelines (UNS N10276+N06200 for high-temperature stability).

• Aerospace & Precision Engineering: Instrument parts, structural components (UNS N07718+N04400 for high toughness).

4. Specification Parameters

Material Combination | Thickness Range | Surface Finish | Manufacturing Process | Core Performance |

UNS N06455 + N06022 | 0.8mm–16mm | Polished/Brushed | Cold Rolled/Hot Rolled | Chemical corrosion resistance |

UNS N10276 + N06200 | 0.8mm–16mm | Smooth/Matte | Annealed/Hot Rolled | High-temperature stability |

UNS N08800 + N08825 | 0.8mm–16mm | Brushed/Polished | Cold Rolled | Saltwater corrosion resistance |

UNS N10675 + N09925 | 0.8mm–16mm | Polished | Cold Rolled | Food safety, easy cleaning |

UNS N07718 + N04400 | 0.8mm–16mm | Smooth | Annealed | High toughness, fatigue resistance |

5. Quality Assurance & After-Sales

All products comply with international industry standards (e.g., ASTM, DIN). We provide material certification, dimensional reports, and technical consultation to support your application. For custom requirements (e.g., specific thickness, surface finish), contact our engineering team for tailored solutions.

Send Inquiry to This Supplier

You May Also Like

-

Rust Proof S32750/F55/S32760/F60 Stainless Steel Coils Reliable Manufacturer for Refrigeration Equipment and FreezersNegotiableMOQ: 1 Ton

-

S32205/SUS329J1/1.4460/254SMO High Ductility Stainless Steel Coils Factory Price for Sheet Metal Forming and ProcessingNegotiableMOQ: 1 Ton

-

Direct Factory Supply Bright Surface Stainless Steel Coils F44/S31254/1.4547/XM19 for Furniture and Decoration ProjectsNegotiableMOQ: 1 Ton

-

S20910/Gr660/SUH660/316Ti High Toughness Stainless Steel Coils Professional Manufacturer for Heavy Machinery PartsNegotiableMOQ: 1 Ton

-

Anti Scratch Stainless Steel Coils S31668/1.4529/N08367/N08926 Factory Made for Construction Curtain Wall and RoofingNegotiableMOQ: 1 Ton

-

Factory Direct Precision Cut Stainless Steel Coils S31608/S31609/316H/347H for Medical Device and Laboratory EquipmentNegotiableMOQ: 1 Ton

-

Light Weight SUS34778/S34779/304H/S30409 Stainless Steel Coils Custom Manufacturer for Aviation Interior DecorationNegotiableMOQ: 1 Ton

-

S321H/S32169/317L/S31703 High Gloss Stainless Steel Coils Factory Supply for Elevator Cabin and Door PanelsNegotiableMOQ: 1 Ton

-

Wear Proof Stainless Steel Coils S25073/2507/1.4435/724L Factory Price for Conveyor Belt and Industrial LinersNegotiableMOQ: 1 Ton

-

Anti Corrosion 174PH/SUS630/F51/2205 Stainless Steel Coils Trusted Manufacturer for Chemical Tank LiningNegotiableMOQ: 1 Ton