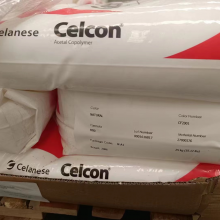

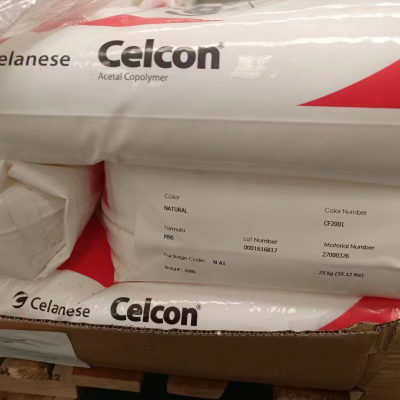

Celanese POM Celcon S9364 Pom Granules Food Grade Plastic Material

Feel free to contact us with any questions. If you have any doubt about the price, we can give a proper discount by different purchasing quantity. Scope of application It is suitable for making wear-resistant parts, transmission parts, chemical and instrument parts. It has the characteristics of rigidity and high wear resistance. It is mainly used for gears, bearings, auto parts, machine tools, instrument internals and other products that play a skeleton role. Product features (1) The POM can not be dried before processing. It is better to preheat (about 80 ℃) during processing, which is good for the stability of product size; (2) The processing temperature of POM is very narrow (0~215 ℃), and when it stays in the barrel for a long time or the temperature exceeds 220 ℃, it will decompose and produce highly irritating formaldehyde gas; (3) When POM material is injected, the pressure retaining pressure should be larger (close to the injection pressure) to reduce the pressure drop. The screw speed should not be too high and the residual amount should be less; (4) The POM product has a large shrinkage rate and is prone to shrinkage or deformation. The POM has a large specific heat and a high mold temperature (80~100 ℃). The product is very hot when demoulding, so it is necessary to prevent scalding fingers; (5) POM should be formed and processed under the conditions of "medium pressure, medium speed, low material temperature and high mold temperature". The mold temperature should be controlled when forming precision products (6)High mechanical strength and rigidity; (7) Maximum fatigue strength; (8) Good environmental resistance and organic solvent resistance; (9) It has strong resistance to repeated impact, good electrical properties, good resilience, good self-lubrication, good wear resistance, and excellent dimensional stability. | ||||||||

Send Inquiry to This Supplier

You May Also Like

-

DuPont POM Delrin 127UV BK601 Pom Plastic Weather Resistance and Ultraviolet Resistance Pom GranulesUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

DuPont POM Delrin 100ST NC010 Pom Granules Low Temperature Resistance Pom Raw MaterialUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

Pom Plastic DuPont POM Delrin 527UV BK701 Weather Resistance and Ultraviolet Resistance Pom GranulesUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

DuPont POM Delrin 500AF Pom Granules Injection Molded Polyoxymethylene Wear-resistant High Flow Pom MaterialUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

DuPont POM Delrin 500T NC010 Plastic Material Low Temperature ResistanceUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

DuPont POM Delrin 100 Pom Granules Toughening Gear Bearing Special Material High Lubricating POM RESINUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

DuPont POM Delrin 500CL NC010 Plastic Material Toughening Gear Bearing Special Material High Lubricating Polyoxymethylene RESINUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

DuPont POM Delrin 100T Pom Granules Toughening Gear Bearing Special Material High Lubricating Pom PelletsUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

DuPont POM 500AL Pom Granules High Toughness and High Strength Engineering PlasticsUS$ 1.50 - 2.50MOQ: 25 Kilograms

-

Korea Kepital POM F25-03H Pom Granules High Temperature Resistance Engineering PlasticsUS$ 1.50 - 2.50MOQ: 25 Kilograms