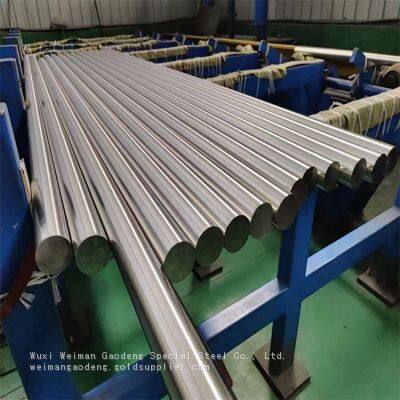

1.321 Stainless Steel Rod, Polished Surface & Corrosion Resistant, Precision Size S32100 Stainless Steel Round Bar

ASTM A479 Stainless Steel Bars: Full-Range Industrial Solution for Diverse Applications

We specialize in manufacturing ASTM A479-compliant stainless steel bars that cover all grades you need—from austenitic to super duplex, heat-resistant to biocompatible. Each bar is engineered to meet strict industrial standards, with customizable forms and processing to match your exact workflow requirements.

1. Product Overview: Grades & Core Advantages

Our portfolio fully covers the stainless steel grades you specified, categorized by performance to simplify your selection:

Category | Grades Included | Key Trait | Typical Use Case |

Austenitic (Acid/Heat) | N08020/Alloy20, N08367, N08800/800, N08810/800H, N08811, N08904/904L, N08926 | High Ni/Mo content, anti-acid/oxidation | Chemical tanks, marine, high-temp furnaces |

Austenitic (General) | S30400/304, S30403/304L, S30908/309S, S31008/310S, S31603/316L, S31609/316H, S31636/316Ti, S31653/316LN, S31703/317L, S32100/321, S32109/321H, S34709/347H, S31254, S32654 | Balanced corrosion/strength, easy processing | Food/pharma, architecture, power plants |

Duplex/Super Duplex | S31803/S32205 (2205), S32304, S32615, S32750/2507 | Ultra-high strength, low alloy cost | Offshore pipelines, sewage treatment |

Precipitation Hardening | S20910/XM-19, S21800 | High tensile strength, light weight | Aerospace fasteners, medical tools |

All grades comply with ASTM A479’s chemical and mechanical requirements—e.g., minimum tensile strength of 515 MPa for 316L, 1000℃ continuous service temp for S310S, and PREN (Pitting Resistance Equivalent Number) ≥40 for S32654.

2. Application-by-Industry: Tailored Performance

We’ve aligned each grade with its optimal industrial scenario, based on the use cases in your titles:

Chemical & Petrochemical

• Grades: N08020/Alloy20, S316L, S32615, S31254

• Performance: Resist concentrated sulfuric acid (98%), chlorine gas, and H₂S corrosion (critical for oil wells). For example, Alloy20’s 30% Ni content prevents acid-induced stress cracking, while S32615 (super duplex) has a PREN ≥45 for chloride environments.

• Forms/Processing: Hollow bars for reactor tubes, solid round bars for valve stems, with CNC drilling and sandblasting finish.

Marine & Offshore

• Grades: N08367, S32654, S31803/2205, S32750/2507

• Performance: Seawater/brine resistance (no pitting after 1000-hour salt spray test). N08367’s 24% Cr + 6% Mo withstands marine pile corrosion; 2507 (super duplex) offers 2x the strength of 316L for subsea valves.

• Forms/Processing: Hexagonal bars for platform structures, threaded bars for subsea fittings, precision cutting-to-length (tolerance ±0.1mm).

High-Temperature (1000-1200℃)

• Grades: N08800/800, N08810/800H, S309S, S310S, S321H

• Performance: Creep resistance (no deformation at 800℃ for 10,000 hours). S310S’s 25% Cr + 20% Ni resists carburization in refractory ovens; 800H’s controlled carbon content (0.05-0.10%) ensures stability in furnace liners.

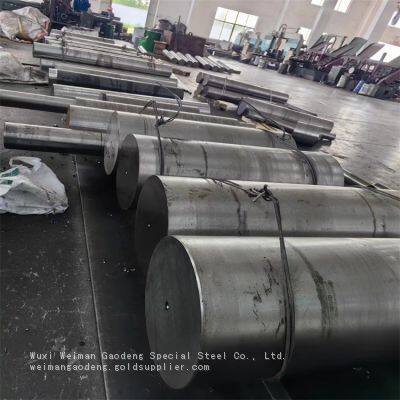

• Forms/Processing: Rectangular bars for kiln linings, thick-walled bars for heater tubes, forging processing to enhance high-temp strength.

Food, Pharma & Medical

• Grades: N08904/904L, S304L, S316L, S21800

• Performance: Food-grade (FDA 21 CFR 177.2600 compliant) and biocompatible. 904L’s low carbon (<0.02%) avoids intergranular corrosion in wine vats; S21800 (precipitation hardening) is non-toxic for surgical scalpel blanks (hardness HRC 40-45).

• Forms/Processing: Mirror-polished square bars (Ra ≤0.8μm) for mixers, thin bars for dental instruments, stamping for tableware blanks.

Aerospace & Power

• Grades: S20910/XM-19, S21800, S321, S347H

• Performance: High tensile strength (XM-19: ≥1100 MPa) and radiation resistance (316LN for nuclear pipes). S321’s titanium stabilization prevents sensitization in jet engine exhausts; S347H’s niobium content resists creep in boiler headers.

• Forms/Processing: Small-diameter threaded bars for aerospace fasteners, stepped bars for turbine parts, precision milling (tolerance ±0.05mm).

3. Form & Processing: Fully Customizable

We offer flexible forms and processing to match your end-product design—no need for secondary machining:

• Bar Forms:

◦ Solid: Round (3-300mm OD), hexagonal (6-80mm across flats), square (5-100mm), rectangular (10×20 to 50×100mm)

◦ Hollow: Seamless (10-200mm OD, 1-20mm wall thickness)

◦ Precision: Cold-drawn bars (diameter tolerance H9) for medical/aerospace use

• Surface Finish:

◦ Industrial: Black oxide, sandblasted (Ra 12.5μm)

◦ Food/Pharma: Mirror polish (Ra ≤0.2μm), brush finish (Ra 1.6μm)

• Processing Services:

◦ Cutting: CNC cutting-to-length (max 6m, tolerance ±0.5mm)

◦ Machining: Drilling, milling, turning, threading (ISO metric/UNC threads)

◦ Heat Treatment: Solution annealing (for austenitic grades), aging (for precipitation hardening grades)

4. Quality Assurance: Traceable & Compliant

Every batch of ASTM A479 stainless steel bars undergoes strict quality control to ensure reliability:

• Testing Protocols:

◦ Chemical Analysis: ICP-OES for Ni, Mo, Cr content (accuracy ±0.01%)

◦ Mechanical Testing: Tensile strength, yield strength, elongation (per ASTM A370)

◦ Corrosion Testing: Salt spray (ASTM B117), pitting resistance (ASTM G48)

◦ Dimensional Inspection: Laser diameter measurement, straightness test (<1mm/m)

• Certifications:

◦ Material Traceability: MTC (Mill Test Certificate) per EN 10204 3.1

◦ Compliance: FDA (for food-grade), ISO 9001, ASME BPVC (for pressure vessels)

• Production Control: Raw material sourced from certified mills (e.g., Outokumpu, Aperam), in-line defect detection (eddy current testing for hollow bars).

5. Why Choose Us?

• One-Stop Supply: Cover all your required grades—no need to source from multiple vendors.

• Technical Support: Our metallurgists help match grades to your application (e.g., recommend 2507 over 316L for subsea use to cut 30% maintenance cost).

• Fast Lead Time: 7-15 days for standard sizes (304L, 316L); 20-30 days for custom grades/processing.

• Flexible MOQ: 10kg for small-batch trials, bulk discounts for orders over 1000kg.

Contact us today with your drawing or grade requirement—we’ll provide a free quote and technical datasheet within 24 hours. Your reliable ASTM A479 stainless steel bar partner for industrial success.

Send Inquiry to This Supplier

You May Also Like

-

S31254 Stainless Steel Round Bar, Cold Drawn & Corrosion Resistant, High Strength Stainless Steel Rod for Chemical TankNegotiableMOQ: 10 Kilograms

-

S31803 Stainless Steel Round Bar, Duplex Series With Polished Surface & High Toughness, Corrosion Resistant Stainless Steel RodNegotiableMOQ: 10 Kilograms

-

S31803 Stainless Steel Round Bar, Duplex Series With Polished Surface & High Toughness, Corrosion Resistant Stainless Steel RodNegotiableMOQ: 10 Kilograms

-

S32205 Stainless Steel Round Bar, 2205 Duplex With Cold Drawn & Precision Size, High Strength Stainless Steel RodNegotiableMOQ: 10 Kilograms

-

2205 Stainless Steel Rod, Duplex Alloy & Corrosion Resistant, Industrial Grade S32205 Stainless Steel Round BarNegotiableMOQ: 10 Kilograms

-

S32100 Stainless Steel Round Bar, 321 Series With High Temperature Resistant, Hot Rolled Stainless Steel Rod for AviationNegotiableMOQ: 10 Kilograms

-

S32750 Stainless Steel Round Bar, 2507 Duplex With Cold Drawn & Corrosion Resistant, High Strength Stainless Steel RodNegotiableMOQ: 10 Kilograms

-

2507 Stainless Steel Rod, Duplex Alloy & High Toughness, Industrial Grade S32750 Stainless Steel Round BarNegotiableMOQ: 10 Kilograms

-

N08020 Stainless Steel Rod, Cold Drawn & Precision Diameter 7mm-110mm, Corrosion Resistant Alloy20 Stainless Steel Round BarNegotiableMOQ: 10 Kilograms

-

Alloy20 Stainless Steel Round Bar, Hot Rolled & High Strength, Polished Surface N08020 Stainless Steel Rod for ValveNegotiableMOQ: 10 Kilograms