OEM Customized Forged Steel Pinion Bearing Housing for Cement Plant

OEM Customized Forged Steel Pinion Bearing Housing for Cement Plant

Introduction

In the demanding environment of a cement plant, reliable and high - performance components are crucial for smooth operations. Our OEM customized forged steel pinion bearing housing is specifically designed to meet the unique requirements of cement plants. This product is the result of advanced manufacturing techniques and high - quality materials, ensuring long - term durability and efficient performance.

Product Features

1. Corrosion Resistance

One of the most significant challenges in a cement plant is the presence of corrosive substances. Our forged steel pinion bearing housing is treated with a special anti - corrosion coating. This coating forms a protective barrier that shields the housing from the corrosive effects of chemicals, moisture, and dust commonly found in cement production environments. As a result, the housing can withstand the test of time, reducing the need for frequent replacements and maintenance.

2. High - Temperature Resistance

Cement plants often operate at high temperatures. Our bearing housing is made from high - grade forged steel that can tolerate extreme heat. The material has a high melting point and excellent thermal stability, which means it can maintain its structural integrity even when exposed to high - temperature conditions for extended periods. This feature is essential for preventing deformation and ensuring the proper functioning of the pinion bearings within the housing.

3. High - Speed Performance

The pinion in a cement plant operates at high speeds, and the bearing housing must be able to support this rapid movement. Our housing is precisely engineered to minimize friction and vibration during high - speed operation. The internal surface of the housing is machined to a high degree of smoothness, which reduces wear and tear on the bearings. Additionally, the design of the housing provides optimal support for the bearings, allowing them to rotate at high speeds without compromising performance or safety.

Customization Options

1. OEM Customization

We understand that every cement plant has its own specific requirements. That's why we offer OEM customization services for our forged steel pinion bearing housing. Our experienced engineering team can work closely with you to design a housing that fits your exact specifications. Whether it's the size, shape, or mounting configuration, we can tailor the product to meet your needs.

2. Material Selection

In addition to the standard high - grade forged steel, we also offer a range of material options for the bearing housing. Depending on your specific operating conditions, we can select materials with different properties, such as increased hardness or improved ductility. This flexibility allows us to provide a solution that is perfectly suited to your cement plant's unique environment.

Manufacturing Process

1. Forging

The manufacturing process starts with high - quality steel billets. These billets are heated to a precise temperature and then forged using state - of - the - art forging equipment. Forging helps to improve the internal structure of the steel, making it stronger and more resistant to fatigue.

2. Machining

After forging, the bearing housing undergoes a series of machining operations. These include turning, milling, and drilling, which are performed with high - precision CNC machines. The machining process ensures that the housing meets the strict dimensional tolerances required for proper installation and operation.

3. Heat Treatment

To further enhance the mechanical properties of the housing, it is subjected to heat treatment. This process involves heating the housing to a specific temperature and then cooling it at a controlled rate. Heat treatment can improve the hardness, toughness, and wear resistance of the steel.

4. Surface Treatment

Finally, the housing is given a surface treatment to protect it from corrosion. This may include painting, galvanizing, or applying a special anti - corrosion coating. The surface treatment not only enhances the durability of the housing but also gives it a clean and professional appearance.

Quality Assurance

1. Testing and Inspection

Before leaving our factory, every forged steel pinion bearing housing undergoes a comprehensive testing and inspection process. We use advanced testing equipment to check for dimensional accuracy, material properties, and surface finish. This ensures that each housing meets our strict quality standards and will perform reliably in your cement plant.

2. Certifications

Our products are certified to meet international quality and safety standards. These certifications are a testament to the high quality and reliability of our OEM customized forged steel pinion bearing housing. You can have full confidence in the performance and durability of our product when you choose it for your cement plant.

Applications in Cement Plants

1. Crushers

In cement crushers, the pinion bearing housing plays a vital role in supporting the high - speed rotation of the pinion. Our housing's high - speed performance and corrosion resistance make it an ideal choice for this application, ensuring smooth operation and long - term reliability.

2. Mills

In cement mills, the pinion is responsible for driving the grinding process. The high - temperature resistance and precise engineering of our bearing housing make it suitable for the demanding conditions in mills, helping to improve the efficiency of the grinding operation.

3. Conveyors

Conveyor systems in cement plants rely on pinions to transfer materials. Our bearing housing's durability and customization options make it a perfect fit for conveyor applications, reducing downtime and maintenance costs.

In conclusion, our OEM customized forged steel pinion bearing housing is a high - quality, reliable solution for cement plants. With its excellent features, customization options, and strict quality control, it is designed to meet the most demanding requirements of the cement industry.

Send Inquiry to This Supplier

You May Also Like

-

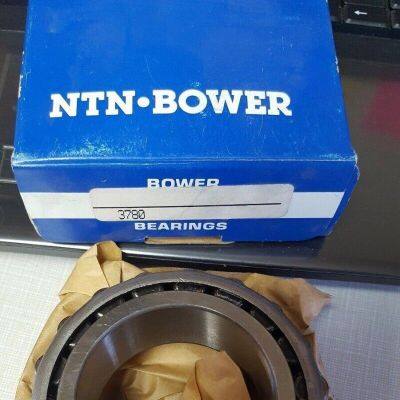

NTN NSK Koyo or OEM Manufacture Plummer Block Split Sn Snl Bearing HousingNegotiableMOQ: 50 Pieces

-

NSK NTN Fyh NACHI Asahi SKF Pillow Block Bearing SN217/SN218/SN219 Bearing HousingNegotiableMOQ: 50 Pieces

-

Vertical Bearing SN220/SN222 Pillow Block Bearing Housing SN224 for Conveyor Belt MachineNegotiableMOQ: 50 Pieces

-

Bearing Housing Unit SN217/SN218 Pillow Block Bearings SN219NegotiableMOQ: 50 Pieces

-

Bearing Housing With Seat Bearing SN214/SN215/SN216 Vertical BearingNegotiableMOQ: 50 Pieces

-

NTN Wholesale Bearing Distributors High Quality SN209/SN210/SN212/SN213 Block Bearing HousingNegotiableMOQ: 50 Pieces

-

Vertical Housing Unit SN214/SN215/SN216, Insert Ball Bearing for Agriculture MachineryNegotiableMOQ: 50 Pieces

-

China Manufacturer Price High Precision Heavy Duty Bearing Housing SN220/SN222/SN224NegotiableMOQ: 50 Pieces

-

Pillow Block Bearing SN230/SN232 Vertical Mounted Flange HousingNegotiableMOQ: 50 Pieces

-

Agriculture Machinery Bearing Adjustable Pillow Block Bearing Housing SN217/SN218/SN219NegotiableMOQ: 50 Pieces