Structural S32304 Stainless Steel Plate & Strip - Durable Cold-Rolled

High-Performance Stainless Steel Sheets & Strips: Comprehensive Product DetailsIntroduction

Our stainless steel sheets and strips are engineered to excel in the most demanding industrial environments, covering a diverse range of high-grade alloys—from austenitic and duplex to super austenitic grades. With a portfolio including N08020 (Alloy 20), 316L, 904L, 2205, 2507, and more, we deliver solutions tailored to resist corrosion, withstand extreme temperatures, and maintain structural integrity. Each product adheres to international standards (ASTM A240, ASME SA-240, etc.) and undergoes rigorous testing, ensuring reliability for critical applications worldwide.

Technical Parameters Table

Material Code | Common Name/Alloy | Key Alloy Composition (Typical) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Max Service Temp (°C) | Primary Corrosion Resistance |

N08020 | Alloy 20 | 20Cr-35Ni-2Mo-Cu | 550–750 | ≥240 | ≥30 | 600 | Sulfuric acid, phosphoric acid, chloride solutions |

N08367 | AL-6XN | 21Cr-24Ni-6Mo-1.5Cu-N | 650–850 | ≥310 | ≥35 | 815 | Seawater, sour gas (H₂S), high-chloride environments |

N08800/800 | Alloy 800 | 21Cr-32Ni-3Al-Ti | 550–750 | ≥205 | ≥30 | 1095 | High-temperature oxidation, furnace atmospheres |

N08904/904L | 904L | 20Cr-25Ni-4.5Mo-Cu | 520–720 | ≥205 | ≥35 | 315 | Strong acids (sulfuric, hydrochloric), organic solvents |

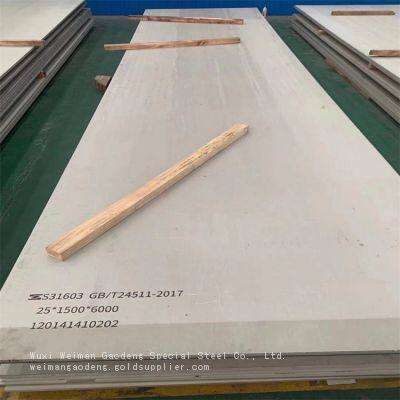

S31603/316L | 316L | 18Cr-12Ni-2.5Mo (Low C) | 515–700 | ≥205 | ≥40 | 870 | Mild acids, seawater, pharmaceutical-grade environments |

S32205/2205 | 2205 Duplex | 22Cr-5Ni-3Mo-N | 620–850 | ≥450 | ≥25 | 315 | Sour oil/gas, high-pressure seawater, chemical processing |

S32750/2507 | 2507 Super Duplex | 25Cr-7Ni-4Mo-N | 800–1100 | ≥550 | ≥25 | 315 | Extreme chloride corrosion (pitting/crevice), offshore drilling |

S31254 | 254SMO | 20Cr-18Ni-6Mo-1Cu-N | 650–850 | ≥310 | ≥40 | 315 | Seawater desalination, acidic brines, pulp & paper industries |

Product Details

• Form & Dimensions: Available as sheets (thickness: 0.3mm–150mm; width: 1000mm–2000mm; length: 2000mm–6000mm) and strips/coils (thickness: 0.1mm–3mm; width: 10mm–600mm). Hot-rolled sheets (≥3mm) offer superior toughness for heavy-duty applications, while cold-rolled sheets/strips (≤3mm) provide precision flatness and surface finish for tight-tolerance parts.

• Surface Treatments: Standard finishes include:

◦ 2B (cold-rolled, bright; Ra ≤0.8μm) – ideal for food/pharmaceutical equipment;

◦ No.4 (brushed, 120–180 grit; Ra 0.4–1.6μm) – common in architectural and marine uses;

◦ HL (hairline; directional finish) – for decorative and industrial panels;

◦ Mirror (No.8; Ra ≤0.025μm) – for aesthetic or high-visibility applications.Custom finishes (pickled, sandblasted) available upon request.

• Processing Capabilities: We offer precision cutting (laser, plasma, water jet), shearing, and forming to meet custom (dimensions). Heat treatments (annealing, solution annealing) optimize microstructure—critical for duplex and high-temperature alloys to ensure stability in service.

• Quality Assurance: Every batch includes a Mill Test Report (MTR) certifying chemical composition, mechanical properties, and compliance with ASTM/ASME standards. Third-party inspections (SGS, TÜV) and traceability documentation are provided for critical industries like nuclear and aerospace.

Product Applications

Our stainless steel sheets and strips serve a wide range of industries, leveraging material-specific strengths:

• Chemical & Petrochemical: Tanks, reactors, and piping using N08020, 904L, and S31254 to resist aggressive acids (sulfuric, hydrochloric) and solvent exposure.

• Oil & Gas: Offshore platforms, drill pipes, and valves with 2205, 2507, and N08367 to withstand sour gas (H₂S) and seawater corrosion in deepwater environments.

• Food & Pharmaceutical: Hygienic tanks, conveyors, and mixing equipment with 304L and 316L, valued for low carbon content (to avoid contamination) and easy sanitization.

• Power Generation: Boiler tubes, heat exchangers, and turbine components using N08800, 310S, and 321H, which maintain strength and oxidation resistance at temperatures up to 1100°C.

• Aerospace & Automotive: Structural parts and exhaust systems with S20910 (Nitronic 50) and 309S, chosen for high tensile strength and resistance to thermal fatigue.

Product Performance

• Corrosion Resistance: All alloys resist uniform corrosion; super austenitic (904L, S31254) and super duplex (2507) grades excel in pitting and crevice corrosion (PREN ≥40), making them ideal for seawater and high-chloride environments.

• High-Temperature Stability: Alloys like N08800, 310S, and 321H retain strength and oxidation resistance at temperatures up to 1100°C, critical for furnace linings and turbine parts.

• Mechanical Strength: Duplex (2205) and super duplex (2507) alloys offer twice the yield strength of austenitic grades (e.g., 316L), reducing material thickness and weight in structural applications.

• Weldability: Most grades (304L, 316L, 2205) are readily weldable with proper techniques (GTAW, GMAW), ensuring ease of fabrication into complex components.

About Our Factory

With over 15 years of experience, we are a leading manufacturer of high-performance stainless steel sheets and strips. Our state-of-the-art facility is equipped with advanced rolling mills, vacuum heat treatment furnaces, and in-house testing labs (metallography, tensile testing, corrosion testing). We are ISO 9001:2015 certified and comply with strict quality controls to meet ASTM, ASME, and EN standards. Our team of metallurgical engineers provides technical support from material selection to post-delivery, ensuring tailored solutions for unique customer needs. We supply to 50+ countries, with a reputation for on-time delivery and consistent quality. Partner with us for reliable, high-performance stainless steel solutions.

Contact us today for a custom quote or technical consultation!

Send Inquiry to This Supplier

You May Also Like

-

Chemical Storage N08904 904L Stainless Steel Strip & Plate - Acid-Resistant PolishedNegotiableMOQ: 10 Kilograms

-

Offshore Platforms N08926 Stainless Steel Sheet & Strip - Durable Hot-RolledNegotiableMOQ: 10 Kilograms

-

Aerospace S20910 XM-19 Stainless Steel Plate & Strip - High-Strength AnnealedNegotiableMOQ: 10 Kilograms

-

Automotive Parts S30400 304 Stainless Steel Sheet & Strip - Weldable PolishedNegotiableMOQ: 10 Kilograms

-

Medical Equipment S30403 304L Stainless Steel Strip & Plate - Corrosion-Resistant Cold-RolledNegotiableMOQ: 10 Kilograms

-

Furnace Linings S30908 309S Stainless Steel Sheet & Strip - Oxidation-ResistantNegotiableMOQ: 10 Kilograms

-

Kiln Parts S31008 310S Stainless Steel Plate & Strip - High-Heat Hot-RolledNegotiableMOQ: 10 Kilograms

-

Pharmaceutical Tanks S31603 316L Stainless Steel Strip & Sheet - Hygienic AnnealedNegotiableMOQ: 10 Kilograms

-

Heat Exchangers S31609 316H Stainless Steel Sheet & Strip - High-Temp MachinableNegotiableMOQ: 10 Kilograms

-

Pipeline Systems S31636 316Ti Stainless Steel Plate & Strip - Weldable Cold-RolledNegotiableMOQ: 10 Kilograms