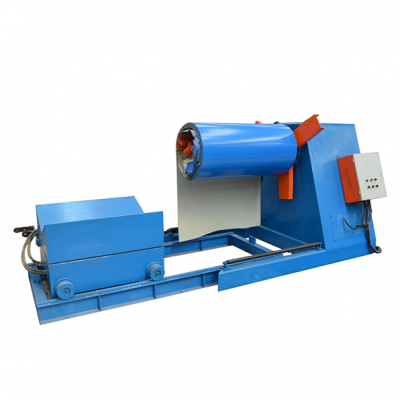

Howann Hydraulic PPGI/GI/Alu Sheet Panel Hot-selling High-effective Decoiler Machine

1, hydraulic heavy uncoiling machine is mainly used for more than 2 t heavy material feeding decoiling, the fuselage structure andprocessing technology not only has the very big, at the same time with the hand expansion of hydraulic expansion method instead of the standard approach, greatly reduces the labor intensity, saving on time, and ensure the stability of the feeding to a great extent and security.

2. The material rack has automatic pressure maintaining function, which can prevent loose material.

3. The material rack has automatic braking function, which prevents the material inertia pulling the motor base, and has the material frame to loosen the limit function to prevent pulling the oil cylinder.

4. Four-leaf blade design, the blade curve is in accordance with the inner diameter of the material, the blade surface is hard plated, smooth and abrasion resistant, and the material will not be damaged during the operation.

5. A quick change structure for A frame, quick and strong replacement, no damage to the blade.

6. The main motor drive is driven by the decelerator motor, with vector frequency conversion control, and driven by the sprocket.

7. Main frame: after the welding of steel, A3 steel plate and #45 steel forging, it is not deformed by the qualitative treatment of annealing; Two bearing a bore, and guarantee the concentricity of main shaft installation, do not produce radial run out, tiles for high strength steel, rack for forging steel core shaft, supporting rod for high strength cast steel, make sure it's strong and durable, long service life.

8, using the latest design, make the machine more reasonable and practical, and process control of material changes in the rate of volume, according to the coil diameter change automatic deceleration, the device must reach the lightest load, greatly increase its service life, reduce the failure rate.

1. Inquiry and consulting support

2. Sample testing support

3. Recommend the most suitable machine according to customer's purpose

4. Factory visiting welcomed

After-sales Service:

1. Training how to install the machine

2. Training how to use the machine

3. Warranty 1 year

4. Engineers available to service machinery oversea

Send Inquiry to This Supplier

You May Also Like

-

Automatic Air Conditioning Flexible Duct Connector MachineUS$ 29800 - 32000MOQ: 1 Piece

-

Fast Delivery Sheet Metal Roofing Curving Machine Pressing Curve Forming MachineUS$ 5850 - 6850MOQ: 1 Piece

-

China Manufacturer Automatic Galvanized Coil Slit Flat Cut to Length Line Metal Strip Coil Steel Coil Length Cutting MachineUS$ 11500 - 13500MOQ: 1 Piece

-

Hot Selling 4-40mm Rebar Bender Manual Rebar Bender Heavy Duty Circle CNC GW50 Steel Bar Bending MachineUS$ 600 - 680MOQ: 1 Piece

-

Innovative Multi-Function Bending Technology for Steel Bar Future Rebar Processing-Motor Compatible Stainless Steel Carbon SteelUS$ 350 - 420MOQ: 1 Piece

-

New Arrival GQ40 Steel Bar Cutter Rebar Cutting MachineUS$ 550 - 650MOQ: 1 Piece

-

Good Price Hydraulic Circular Thread Rolling MachineUS$ 3080 - 3680MOQ: 1 Piece

-

Automatic Rebar Thread Rolling & Cutting Machine Fast Delivery Core Component Motor for Construction & Pipe IndustriesUS$ 600 - 720MOQ: 1 Piece

-

25mm Electric Drill Tapping Machine Variable Speed Magnetic Drill Press for Metal Drilling Customized OEM SupportUS$ 368 - 468MOQ: 1 Piece

-

Small Mini Portable Vibratory Road Asphalt Compactor Equipment Road RollerUS$ 1150 - 1250MOQ: 1 Piece