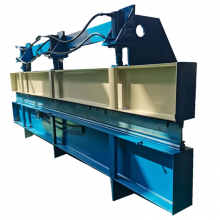

4000mm Width Hydraulic Bending Machine Best Price Metal Sheet Bender Machinery

The bending machine is a machine that can bend thin plates. Its structure mainly includes a bracket, a working table and a

clamping plate.

Features for folding machine:

1. Adopt all-steel welded structure, with sufficient strength and rigidity;

the machine tool are placed on the sliding block to directly drive the sliding work;

adopts torsion shaft for forced synchronization;

Operating procedures:

1. First, turn on the power, turn on the key switch on the control panel, and then press the oil pump to start.

4. Backgauge adjustment generally includes electric quick adjustment and manual fine adjustment

5.Step on the foot switch to start bending. The bending machine is different from the shearing machine. You can release it at anytime. When you release your foot, the bending machine will stop, and then step on to continue downward.

1.Need one 40ft container.

2.The main body of the roll forming machine will be naked packed into the container, covered with plastic film.

3.Steel wire fix the machine into the container, in case any damage on the sea.

4.The spare parts will be packed into the carton box.

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 15 to 30 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

Send Inquiry to This Supplier

You May Also Like

-

Hot Sale Automatic Galvanized Tile Ridge Machine Steel Ridge Making MachineUS$ 6800 - 7500MOQ: 1 Piece

-

Full Automatic Used Half Round Seamless Water Rain Gutter Roll Forming Machine Downspout Making Machine Gutter Machines for SaleUS$ 6500 - 7800MOQ: 1 Piece

-

High Speed Round and Square Downspout Water Gutter Pipe Bending Roll Forming MachineUS$ 19800 - 29800MOQ: 1 Piece

-

2 Layers Roofing Panel Making Machine Roof Tile Roll Forming Machine South Africa Ibr Double Layer Roll Forming MachineUS$ 7200 - 7900MOQ: 1 Piece

-

China Supplier Metal Roofing Panel Sheet Roll Forming Machine Profiling Tiles Making Machine for Building Material MachineryUS$ 4865 - 5850MOQ: 1 Piece

-

Factory Direct Special-Shaped Tile Pressing Roll Forming Machine Low Price for Roof Use Essential Engine Gear Bearing Motor PumpUS$ 6200MOQ: 1 Piece

-

New Arrival Soffit Panel Roll Forming Machine Metal Ceiling Panel Roll Forming Machine With Automatic CutterUS$ 17500 - 19500MOQ: 1 Piece

-

Hot Selling Self Click Lock Roof Roll Forming Machine Standing Seam Roll Forming Machine for Roofing MachineryUS$ 7600 - 8500MOQ: 1 Piece

-

Fast Delivery Standing Seam Roofing Panel Roll Forming MachineUS$ 8300 - 10500MOQ: 1 Piece

-

Steel Ridge Cap Roll Forming Machine 840 IBR Roof Sheet Use PLC Control System for Tile Making IndustriesUS$ 6800 - 7500MOQ: 1 Piece