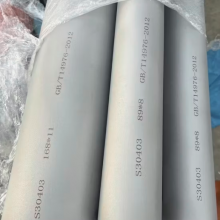

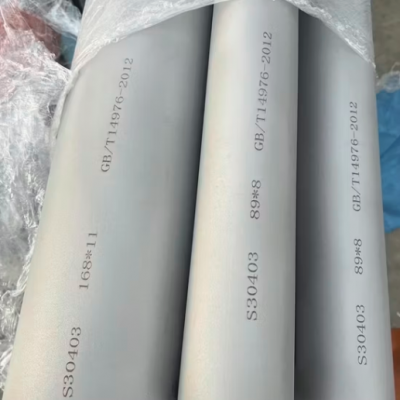

ASTM 304 321 316L Brushed, Colored, Polished Mirror 8K Ba Bright Seamless Welded Seamless Round ERW ASTM JIS DIN Stainless Steel Pipe

Stainless steel pipe is a tubular material made of stainless steel, which has the characteristics of excellent corrosion resistance, high strength, long service life and good hygiene performance. It is widely used in petroleum, chemical industry, food, medicine, construction, energy, automobile and other fields.The main material of stainless steel pipes is stainless steel. Common stainless steel brands include:304/304L/316/316L/321/430 etc stainless steel pipe.

| Material | Austenitic 300 series dual grade duplex and super duplex super austenitic stainless steel pipe tube 400 series steel for heat exchanger/condenser/semiconductor/corrosion media transport/chemical and mechanical industry & Precision tube. |

| Standard | GB/T, ANSI, ASTM, ASME, DIN, EN10216, JISG, GOST 9941, etc |

| Surface | Annealing & Pickling, Anneal, passivate, Bright Annealing (BA Finished), Electropolishing (EP), Grinding, Polish, etc. |

| Material (DIN) | 1.4301 1.4306 1.4541 1.4401 1.4404 1.4571 1.4539 1.44621.4410 1.4833 1.4845 |

| Outter Diameter (OD) | 3-1220mm/custom |

| Monthly Supply | 5000 Tons |

| Application | It is widely used in High-temperature and Electrical industry, Medical devices, Heat-exchanger, Boiler, Chemistry, Aerospace, Nuclear power, laboratory, special gas transport, semiconductor, solar and Marine seabed gas and oil transport, liquid Etc. |

| Processing Type | Cutting, bending,welding |

| End/Edge | Plain Mill |

| Service | OEM/ODM service |

| Products N/O | ASME SA 789 UNS 31260 Seamless Pipe | ||||

|---|---|---|---|---|---|

| Brand Name | OEM | ||||

| origin | China | ||||

| Small Orders | Accepted | ||||

| Material | Austenitic 300 series dual grade duplex and super duplex super austenitic stainless steel pipe tube 400 series steel for heat exchanger/condenser/semiconductor/corrosion media transport/chemical and mechanical industry & Precision tube. | |

| Standard | GB/T, ANSI, ASTM, ASME, DIN, EN10216, JISG, GOST 9941, etc | |

| Shape | Seamless welded Round Pipe/Tube, Plate, Sheet, Round Rod(Bar) Rectangular and square | |

| Surface | Annealing & Pickling, Anneal, passivate, Bright Annealing (BA Finished), Electropolishing (EP), Grinding, Polish, etc. | |

| Material Grade | 300 series austenitic | 304 304H 321 321H 316 316L 317 317L 347 347H 309 310S 310H 310 UNS S30815 |

| Duplex and super duplex | Duplex: 31803 UNS S31803 32205 2205 UNS S32205 32304 UNS S32304 Super duplex: 2507 32750 UNS S32750 32760 UNS S32760 | |

| Super austenitic | AL6XN N08367 N08904 904 904L S31254 254SMO | |

| 400 series | 405 410 430 409 439 429 430Ti | |

| Dual grade | 304/304L 304/304l 304/l 316/316L 316/316l 316/L 304/L | |

| Specification | Pipe/Tube range | od 6.35-762mm,wt 0.51-50.8mm ,Length Typically 6096mm |

| Plate/Sheet range | width ≤ 2400mm,Thk≤63.5mm(for rectangular plate) Dia ≤1800mm, Thk≤63.5mm(for round plate) | |

| Application | It is widely used in High-temperature and Electrical industry, Medical devices, Heat-exchanger, Boiler, Chemistry, Aerospace, Nuclear power, laboratory, special gas transport, semiconductor, solar and Marine seabed gas and oil transport, liquid Etc. | |

| Payment terms | 1)30% deposit,the balance against copy of B/L by T/T. 2) 30% deposit by T/T, the balance by irrevocable L/C at sight. | |

| Delivery time | Delivery time: about 2 Months | |

| Samples | Free samples are provided for that length less than 350mm but the freight is borne by the buyer, but we permit to return to buyer after order placed. | |

ASTM A789 UNS 31260 Welded Pipe

Size: 5.0 - 1219.2 mm

Thickness : 0.5 - 20mm

Length: Single, Double Random & Cut Length

Duplex Steel UNS S32550 grade F61 Seamless Pipe Specification

| ASTM A789 UNS 31260 Duplex Stainless Steel Pipe International Specification | ASTM A789/ SA 789, ASTM A790 / SA 790 |

| Standard Specification | ASME, ASTM, AISI, AMS, JIS, EN, SAE, DIN, NF, TOCT, DS, DTD, GB |

| ASTM A789 UNS 31260 Seamless Pipe Size |

|

| Duplex Steel UNS S32550 grade F61 Welded Pipe Size |

|

| ASTM A790 UNS 31260 Duplex Stainless Steel EFW Pipe Size |

|

| SA 789 UNS 31260 Duplex Stainless Steel Pipe WT | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| ASTM A789 31260 Duplex Pipe manufacturing techniques | Seamless / ERW / EFW/ Welded / Fabricated / CDW/ LSAW/ Seam-Welded / Redrawn |

| Origin of UNS S31260 Duplex Stainless Steel pipe material | Indian, European, Korean, Japanese |

| ASME SA 789 31260 Duplex Steel Pipe End Types |

|

| Form | Round, Square, Rectangular |

| UNS S31260 Stainless Steel Pipe Length | Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded |

| SA 789 UNS 31260 Duplex Steel Pipe Delivery Condition | Annealed and Pickled, Hot Finished, Polished, Bright Annealed, Cold Drawn |

| Alloy F255 UNS 31260 Pipe Packing |

|

| A789 UNS 31260 Duplex Steel Pipe Value Added Services | Cut to size, thread, and groove |

| Port | Tianjin ,China |

| Stocking distributor of leading ASTM A789 UNS 31260 Duplex Stainless Steel Pipe manufacturers |

|

| A789 UNS 31260 Duplex Steel Pipe Dimensional Specification | ANSI/ ASME B36.10, B36.19, B2.1 |

| Marking on SA 789 31260 Duplex Steel Pipe |

|

Mill Test Certificates with all ASTM A789 UNS 31260 Duplex Stainless Steel Pipe

EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

Chemical Reports

Mechanical Reports

PMI Test Reports

Visual Inspection Reports

Third Party Inspection for ASTM A789 UNS 31260 Pipe

NABL Approved Lab Reports

Destructive Test Report

Non Destructive Test Reports

100% Radiography Test Report

Fumigation Certificates

Raw Materials Certificate

Moisture testing

Heat Treatment Charts

Surface roughness measurement

HS Code Commercial Invoice

Laboratory Test Certificate from Govt. Approved Lab

Form A for Generalized System of Preferences (GSP)

| Seamless Pipe ASTM A789 UNS 31260 | INR 550/Kg |

| SA240 UNS S31260 Duplex Steel Plate (6 X 1430 X 4350 mm) | INR 340/Kg |

Contact us for Free sample & quote or mail us on info@jiade-group.com

Types of ASTM A789 UNS 31260 Duplex Stainless Steel Pipe

ASTM A789 UNS 31260 Welded Pipe

Duplex Steel UNS S32550 grade F61 Seamless Pipe

ASTM A790 UNS 31260 Duplex Stainless Steel Round Pipe

ASME SA 789 UNS 31260 Rectangular Pipe

SA 789 UNS 31260 Duplex Stainless Steel Square Pipe

ASTM A789 31260 Duplex Schedule 5S Pipe

UNS S31260 Duplex Stainless Steel Schedule 40S Seamless Pipe

ASME SA 789 31260 Duplex Steel Polished Pipe

UNS S31260 Stainless Steel Exhaust Pipe

SA 789 UNS 31260 Duplex Steel Thin Wall Pipe

Alloy F255 UNS 31260 Custom Pipe

A789 UNS 31260 Duplex Steel Cold Drawn Seamless Pipe

SA 789 31260 Duplex Steel Clad Pipe

A789 31260 Duplex Steel ERW Pipe

1.4410 UNS 31260 EFW Pipe

UNS S31260 EN 1.4410 SCH 40 Seamless Pipe

| ASTM A789 UNS 31260 Hot Finished Pipe | Schedule 40S Duplex Steel UNS S32550 grade F61 Pipe |

| A789 31260 Duplex Steel Capillary Pipes | Small diameter Duplex Steel UNS S32550 grade F61 pipes |

| 1.4410 UNS 31260 Clad Pipes | ASTM A790 UNS 31260 Duplex Stainless Steel Annealed pipes |

| Cold Drawn ASTM A790 UNS 31260 Duplex Stainless Steel Pipe | ASME SA 789 UNS 31260 Seam Welded Pipe |

| SA 789 UNS 31260 Duplex Stainless Steel Hollow Pipes | A789 31260 Duplex Steel High pressure Pipes |

| SA 789 UNS 31260 Duplex Stainless Steel Overlay Pipe | ASTM A789 31260 Duplex Bush Hex Pipe |

| ASTM A790 UNS 31260 Duplex Stainless Steel SMLS Pipes | ASME SA 789 UNS 31260 Hexagonal Pipes |

| Thick Wall UNS S31260 Duplex Stainless Steel Pipe | Thin Wall ASME SA 789 31260 Duplex Steel Pipe |

| UNS S31260 Stainless Steel Cold Drawn Seamless Pipe | High Temperature SA 789 UNS 31260 Duplex Steel Pipe |

| Seamless Alloy F255 UNS 31260 Pipe | A789 UNS 31260 Duplex Steel Welded Pipe |

| UNS S31260 Stainless Steel Round Pipes | ASTM A789 31260 Duplex Fabricated Pipes |

| Alloy F255 UNS 31260 Square Pipes | SA 789 31260 Duplex Steel Schedule 5S Pipes |

| SA 789 31260 Duplex Steel ERW Pipe | A789 31260 Duplex Steel EFW Pipe |

| ASTM A789 UNS 31260 CDW Pipes | Duplex Steel UNS S32550 grade F61 Rectangular Pipes |

| UNS S31260 Duplex Stainless Steel Custom Pipes | ASME SA 789 31260 Duplex Steel Beveled End Pipes |

| A789 UNS 31260 Duplex Steel Schedule 40 Pipes | Welded SA 789 UNS 31260 Duplex Steel Cold Drawn Pipes |

| SA 789 31260 Duplex Steel Polished Pipes | ASTM A789 UNS 31260 Exhaust Pipes |

| UNS S31260 EN 1.4410 Rectangle Pipes | Cold Drawn ASME SA 789 UNS 31260 Seamless Pipes |

| NOMINAL | O.D. INCHES | 10S | 10 | 40S & STD | 40 | 80S & E.H. | 80 | 160 |

|---|---|---|---|---|---|---|---|---|

| 1/8 | .405 | .049 | .049 | .068 | .068 | .095 | .095 | |

| 1/4 | .540 | .065 | .065 | .088 | .088 | .119 | .119 | |

| 3/8 | .675 | .065 | .065 | .091 | .091 | .126 | .126 | |

| 1/2 | .840 | .083 | .083 | .109 | .109 | .147 | .147 | .187 |

| 3/4 | 1.050 | .083 | .083 | .113 | .113 | .154 | .154 | .218 |

| 1 | 1.315 | .109 | .109 | .133 | .133 | .179 | .179 | .250 |

| 1 1/4 | 1.660 | .109 | .109 | .140 | .140 | .191 | .191 | .250 |

| 1 1/2 | 1.900 | .109 | .109 | .145 | .145 | .200 | .200 | .281 |

| 2 | 2.375 | .109 | .109 | .154 | .154 | .218 | .218 | .343 |

| 2 1/2 | 2.875 | .120 | .120 | .203 | .203 | .276 | .276 | .375 |

| 3 | 3.500 | .120 | .120 | .216 | .216 | .300 | .300 | .437 |

| 3 1/2 | 4.000 | .120 | .120 | .226 | .226 | .318 | .318 | |

| 4 | 4.500 | .120 | .120 | .237 | .237 | .337 | .337 | .531 |

| 4 1/2 | 5.000 | .247 | .355 | |||||

| 5 | 5.563 | .134 | .134 | .258 | .258 | .375 | .375 | .625 |

| 6 | 6.625 | .134 | .134 | .280 | .280 | .432 | .432 | .718 |

| 7 | 7.625 | .301 | .500 | |||||

| 8 | 8.625 | .148 | .148 | .322 | .322 | .500 | .500 | .906 |

| 9 | 9.625 | .342 | .500 | |||||

| 10 | 10.750 | .165 | .165 | .365 | .365 | .500 | .593 | 1.125 |

| 11 | 11.750 | .375 | .500 | |||||

| 12 | 12.750 | .180 | .180 | .375 | .406 | .500 | .687 | 1.312 |

| 14 | 14.000 | .188 | .250 | .375 | .437 | .500 | .750 | 1.406 |

| 16 | 16.000 | .188 | .250 | .375 | .500 | .500 | .843 | 1.593 |

| 18 | 18.000 | .188 | .250 | .375 | .562 | .500 | .937 | 1.781 |

| NPS | Outside Diameter (OD) | Wall Thickness (WT) | Weight | Weight | |||

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft | |

| 1/2" | 0.840 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| 0.147 | 3.734 | 80 STD | 1.621 | 1.088 | |||

| 3/4" | 1.050 | 27 | 0.113 | 2.870 | 40 STD | 1.684 | 1.131 |

| 0.154 | 3.912 | 80 STD | 2.195 | 1.474 | |||

| 1" | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| 0.179 | 4.547 | 80 STD | 3.325 | 2.172 | |||

| 1 1/4" | 1.660 | 42 | 0.140 | 3.556 | 40 STD | 3.385 | 2.273 |

| 0.191 | 4.851 | 80 STD | 4.464 | 2.997 | |||

| 1 1/2" | 1.900 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| 0.200 | 5.080 | 80 STD | 5.409 | 3.361 | |||

| 2" | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| 0.218 | 5.537 | 80 STD | 7.480 | 5.022 | |||

| 2 1/2" | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| 0.276 | 7.010 | 80 STD | 11.411 | 7.661 | |||

| 3" | 3.500 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| 0.300 | 7.620 | 80 STD | 15.272 | 10.253 | |||

| 4" | 4.500 | 114 | 0.237 | 6.020 | 16.073 | 10.790 | |

| 0.337 | 8.560 | 22.318 | 14.983 | ||||

| 6" | 6.625 | 168 | 0.188 | 4.775 | 19.252 | 12.924 | |

| 0.203 | 5.516 | 20.739 | 13.923 | ||||

| 0.219 | 5.563 | 22.318 | 14.983 | ||||

| 0.250 | 6.350 | 25.354 | 17.021 | ||||

| 0.280 | 7.112 | 40 STD | 58.263 | 18.974 | |||

| 0.312 | 7.925 | 31.334 | 21.036 | ||||

| 0.375 | 9.525 | 37.285 | 25.031 | ||||

| 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0.500 | 12.700 | 48.719 | 32.708 | ||||

| 8" | 8.625 | 219 | 0.188 | 4.775 | 25.233 | 16.940 | |

| 0.203 | 5.156 | 27.198 | 18.259 | ||||

| 0.219 | 5.563 | 29.286 | 19.661 | ||||

| 0.250 | 6.350 | 20 | 33.308 | 22.361 | |||

| 0.277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0.322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0.375 | 9.525 | 49.216 | 33.041 | ||||

| 0.406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0.500 | 12.700 | 80 XHY | 64.627 | 43.388 | |||

| 10" | 10.750 | 273 | 0.188 | 4.775 | 31.588 | 21.207 | |

| 0.219 | 5.563 | 36.689 | 24.631 | ||||

| 0.250 | 6.350 | 20 | 41.759 | 28.035 | |||

| 0.307 | 7.798 | 30 | 51.002 | 34.240 | |||

| 0.344 | 8.738 | 56.946 | 38.231 | ||||

| 0.365 | 9.271 | 40 STD | 63.301 | 40.483 | |||

| 0.438 | 11.125 | 71.852 | 48.238 | ||||

| 0.500 | 12.700 | 60 XHY | 81.530 | 54.735 | |||

| 0.594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12" | 12.750 | 324 | 0.188 | 4.775 | 37.570 | 25.222 | |

| 0.219 | 5.563 | 43.657 | 29.309 | ||||

| 0.250 | 6.350 | 49.713 | 33.375 | ||||

| 0.281 | 7.137 | 55.739 | 37.420 | ||||

| 0.312 | 7.925 | 61.735 | 41.445 | ||||

| 0.375 | 9.525 | 73.824 | 49.562 | ||||

| 0.406 | 10.312 | 79.727 | 53.525 | ||||

| 0.500 | 12.700 | 97.438 | 65.415 | ||||

| 0.562 | 14.275 | 108.966 | 73.154 | ||||

| 14" | 14.000 | 356 | 0.188 | 4.775 | 41.308 | 27.732 | |

| 0.219 | 5.563 | 48.012 | 32.233 | ||||

| 0.250 | 6.350 | 20 | 54.685 | 36.713 | |||

| 0.281 | 7.137 | 61.327 | 41.172 | ||||

| 0.312 | 7.925 | 67.939 | 45.611 | ||||

| 0.375 | 9.525 | STD | 81.281 | 54.568 | |||

| 0.438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0.500 | 12.700 | XHY | 107.381 | 72.090 | |||

| 0.625 | 15.875 | 132.983 | 89.278 | ||||

| 16" | 16.000 | 406 | 0.188 | 4.775 | 47.290 | 21.748 | |

| 0.219 | 5.563 | 54.980 | 36.910 | ||||

| 0.250 | 6.350 | 10 | 62.639 | 42.053 | |||

| 0.281 | 7.137 | 70.268 | 47.174 | ||||

| 0.312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0.344 | 8.738 | 85.677 | 57.519 | ||||

| 0.375 | 9.525 | 30 STD | 93.213 | 62.578 | |||

| 0.438 | 11.125 | 108.433 | 72.797 | ||||

| 0.500 | 12.700 | 40 XHY | 123.289 | 82.770 | |||

| 18" | 18.000 | 457 | 0.219 | 5.563 | 61.948 | 41.588 | |

| 0.250 | 6.350 | 70.593 | 47.393 | ||||

| 0.281 | 7.137 | 79.208 | 53.176 | ||||

| 0.312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0.375 | 9.525 | STD | 105.144 | 70.588 | |||

| 0.438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0.500 | 12.700 | XHY | 139.198 | 93.450 | |||

| 0.562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0.625 | 15.875 | 172.754 | 115.978 | ||||

| 20" | 20.000 | 508 | 0.250 | 6.350 | 78.547 | 52.733 | |

| 0.282 | 7.163 | 88.458 | 59.386 | ||||

| 0.312 | 7.925 | 97.719 | 65.604 | ||||

| 0.375 | 9.525 | 20 STD | 117.075 | 78.598 | |||

| 0.438 | 11.125 | 136.305 | 91.508 | ||||

| 0.500 | 12.700 | 30 XHY | 155.106 | 104.130 | |||

| 0.594 | 15.088 | 40 | 183.378 | 123.110 | |||

| 0.625 | 15.875 | 192.640 | 129.328 | ||||

| 0.688 | 17.475 | 211.368 | 141.901 | ||||

| 24" | 24.000 | 610 | 0.250 | 6.350 | 94.456 | 63.413 | |

| 0.281 | 7.137 | 106.029 | 71.183 | ||||

| 0.312 | 7.925 | 117.573 | 18.932 | ||||

| 0.375 | 9.525 | 20 STD | 140.938 | 64.618 | |||

| 0.438 | 11.125 | 164.176 | 110.219 | ||||

| 0.500 | 12.700 | XHY | 186.923 | 125.490 | |||

| 0.625 | 15.875 | 232.410 | 156.028 | ||||

| 0.688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0.750 | 19.050 | 277.401 | 186.233 | ||||

| 30" | 30.000 | 762 | 0.250 | 6.350 | 118.318 | 79.433 | |

| 0.281 | 7.137 | 132.851 | 89.189 | ||||

| 0.312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0.375 | 9.525 | STD | 176.731 | 118.648 | |||

| 0.438 | 11.125 | 205.983 | 138.286 | ||||

| 0.500 | 12.700 | 20 XHY | 234.647 | 157.530 | |||

| 0.625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0.688 | 17.475 | 320.817 | 215.380 | ||||

| 0.750 | 19.050 | 348.988 | 234.293 | ||||

| 36" | 36.000 | 914 | 0.250 | 6.350 | 142.180 | 95.453 | |

| 0.281 | 7.137 | 159.672 | 107.196 | ||||

| 0.312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0.375 | 9.525 | STD | 215.525 | 142.678 | |||

| 0.438 | 11.125 | 247.790 | 166.353 | ||||

| 0.500 | 12.700 | 20 XHY | 282.372 | 198.570 | |||

| 0.625 | 15.875 | 351.723 | 236.128 | ||||

0.688 | 17.475 | 386.487 | 259.467 | ||||

0.750 | 19.050 | 420.576 | 282.353 | ||||

| 42" | 42.000 | 1067 | 0.312 | 7.925 | 206.914 | 138.911 | |

| 0.375 | 9.525 | STD | 248.319 | 166.708 | |||

| 0.500 | 12.700 | XHY | 33.097 | 221.610 | |||

| 0.750 | 19.050 | 492.163 | 330.413 | ||||

| 48" | 48.000 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| 0.438 | 11.125 | 331.404 | 222.487 | ||||

| 0.500 | 12.700 | XHY | 377.822 | 253.650 | |||

| 0.750 | 19.050 | 563.750 | 378.473 | ||||

| 0.875 | 22.225 | 655.969 | 440.383 | ||||

| NOMINAL SIZE [INCHES] | OUTSIDE DIAMETER (OD) [INCHES] | OUTSIDE DIAMETER (OD) [MM] | WALL THICKNESS [INCHES] | WALL THICKNESS [MM] | WEIGHT [LB/FT] | WEIGHT [KG/M] |

|---|---|---|---|---|---|---|

| 1/8" NPS 6 | 0.41 | 10.3 | 0.068 | 1.73 | 0.24 | 0.37 |

| 1/4" NPS 8 | 0.54 | 13.7 | 0.088 | 2.24 | 0.42 | 0.63 |

| 3/8" NPS 10 | 0.68 | 17.1 | 0.091 | 2.31 | 0.57 | 0.84 |

| 1/2" NPS 15 | 0.84 | 21.3 | 0.109 | 2.77 | 0.85 | 1.27 |

| 3/4" NPS 20 | 1.05 | 26.7 | 0.113 | 2.87 | 1.13 | 1.69 |

| 1" NPS 25 | 1.32 | 33.4 | 0.133 | 3.38 | 1.68 | 2.5 |

| 1 1/4" NPS 32 | 1.66 | 42.2 | 0.14 | 3.56 | 2.27 | 3.39 |

| 1 1/2" NPS 40 | 1.9 | 48.3 | 0.145 | 3.68 | 2.72 | 4.05 |

| 2" NPS 50 | 2.375 | 60.3 | 0.154 | 3.91 | 3.65 | 5.44 |

| 2 1/2" NPS 65 | 2.875 | 73.0 | 0.203 | 5.16 | 5.79 | 8.63 |

| 3" NPS 80 | 3.5 | 88.9 | 0.216 | 5.49 | 7.58 | 11.29 |

| 3 1/2" NPS 90 | 4.0 | 101.6 | 0.226 | 5.74 | 9.11 | 13.57 |

| 4" NPS 100 | 4.5 | 114.3 | 0.237 | 6.02 | 10.79 | 16.07 |

| 5" NPS 125 | 5.563 | 141.3 | 0.258 | 6.55 | 14.62 | 21.77 |

| 6" NPS 150 | 6.625 | 168.3 | 0.28 | 7.11 | 18.97 | 28.26 |

| 8" NPS 200 | 8.625 | 219.1 | 0.322 | 8.18 | 28.55 | 42.55 |

| 10" NPS 250 | 10.75 | 273.0 | 0.365 | 9.27 | 40.48 | 60.31 |

| 12" NPS 300 | 12.75 | 323.8 | 0.406 | 10.31 | 53.52 | 79.73 |

| 14" NPS 350 | 14.0 | 355.6 | 0.437 | 11.13 | 54.57 | 94.55 |

| 16" NPS 400 | 16.0 | 406.4 | 0.5 | 12.7 | 82.77 | 123.3 |

| 18" NPS 450 | 18.0 | 457.0 | 0.562 | 14.27 | 104.67 | 155.8 |

| 20" NPS 500 | 20.0 | 508.0 | 0.594 | 15.09 | 123.11 | 183.42 |

| 24" NPS 600 | 24.0 | 610.0 | 0.688 | 17.48 | 171.29 | 255.41 |

| 32" NPS 800 | 32.0 | 813.0 | 0.688 | 17.48 | 230.08 | 342.91 |

ASME/ ANSI B36.10/ B36.19 - Imperial Units

1 cm2 = 10-4 m2 = 0.155 in2

1 kg = 2.2046 lb

1 m = 3.28 ft

| ELEMENT | COMPOSITION, % |

|---|---|

| Carbon | 0.03 max |

| Manganese | 1.00 max |

| Phosphorus | 0.030 max |

| Sulfur | 0.030 max |

| Silicon | 0.75 max |

| Nickel | 5.50 - 7.50 |

| Chromium | 24.00 - 26.00 |

| Molybdenum | 2.50 - 3.50 |

| Nitrogen | 0.10 - 0.30 |

| Copper | 0.20 - 0.80 |

| Tungsten | 0.10 - 0.50 |

| PROPERTY | VALUE | |

|---|---|---|

| Tensile Stress, min, ksi, [MPa] | 100 [690] | |

| Yield Stress, min, ksi [MPa] | 65 [450] | |

| Elongation in 2 in. or 50mm, min, % | 25 | |

| Hardness, max | HBW | HRC |

| -- | -- | |

| ASTM A790/928 UNS | EN 10216-2 SEAMLESS / EN 10217-5 WELDED | MATERIAL NO. (WNR) |

|---|---|---|

| S31260 | X2CrNiMoN25-7-4 | 1.4410 |

To meet customer requirements, the quality inspector carries out final inspection and test of raw materials and finished pipe products in strict accordance with the inspection standard required by customers. According to stipulated standard requirements, analysis to chemical components of purchased materials and finished products is carried out to strictly control the materials, mechanical properties and chemical properties of finished products are tested, and eddy current test and ultrasonic nondestructive test are carried out, so as to guarantee product quality.

According to the technical conditions and requirements of product standards, the inspector will check the end appearance, bending degree, specified length,outside diameter, wall thickness dimension and internal and external surfaces of finished products one by one. After the product has been found to be up to standard through inspection and test, the quality certification of the product will be issued to ensure that satisfactory and reliable products are delivered to customers.

Shipping:

1. WORLDWIDE SHIPPING. (Except some countries and APO/FPO)

2. Goods delivered by 20" , 40" FCL/LCL by quantity or customer's request.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 7-30days after conformed or according to quantity.

About Us

Zhongzheng Stainless Steel is one of the leading manufacturer and exporter for the Stainless Steel Seamless Pipes & Tubes from China. Based on our Stainless Steel seamless pipe factory, We supply the ONE-STOP service fittings,flanges, valves etc to our customers home and abroad.

We manufacture strictly as per the standard, We have mechanical properties test machine, supersonic testing machine, eddying current test machine, hydrostatic test machine, and spectrum analyzer for chemical composition.etc equipment to insure manufacturing processes and inspection and final quality guarantee.

We welcome customers themselves and/or their appointed third party inspection such as SGS,BV,MOODY, LIoyd's,TUV,DNV Etc well-known third party to conduct the inspection to our company and our products.

Send Inquiry to This Supplier

You May Also Like

-

ASTM Sanitary Tube Pipe AISI/2205/2520 Pickling Duplex Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton

-

Hot Rolled Duplex Stainless Steel Pipe 2507 2520 10mm Thickness Round Oval Silver SeamlessUS$ 800 - 1500MOQ: 1 Ton

-

2520 F55 253mA Duplex Steel Seamless Pipe From ChinaUS$ 500 - 1100MOQ: 1 Ton

-

Low Price ASTM A312 Stainless Steel Tube Industrial JIS Customized Size Stainless Steel PipeUS$ 800 - 1500MOQ: 1 Ton

-

Duplex Steel Tube China Food Grade 2205 2507 (1.4410) Seamless Pipe Od 114.3mm X 3mm X 5m 6m 12m Length CustomizableUS$ 800 - 1100MOQ: 1 Ton

-

Machinery Industry ASTM A249 Duplex 2101 2520 Square 5.8m 1 Inch Stainless Steel Exhaust PipeUS$ 800 - 1500MOQ: 1 Ton

-

ASTM 6mm 6 Inch Duplex 2520 Stainless Steel Rectangular Polished Hexagonal PipeUS$ 800 - 1100MOQ: 1 Ton

-

Duplex Square Pipe Pickling 2205 Stainless Steel Seamless TubeUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A269 6m 2 Inch Square Duplex 2520 2304 Matte Filter Screen Tube With ISO CertificationUS$ 500 - 1100MOQ: 1 Ton

-

2520 High-Temperature Resistant Stainless Steel Pipe, 2507 Duplex Stainless Steel 273*8 Seawater Desalination PipeUS$ 800 - 1100MOQ: 1 Ton