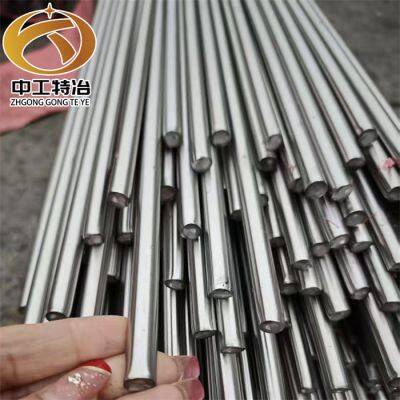

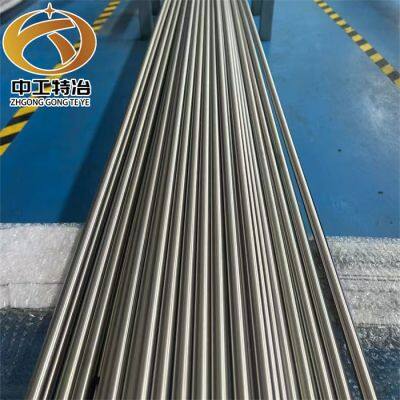

304 321 316L 309S Stainless Steel Rod Grinding Rod Bright Rod Manufacturers Support Processing

304 321 316L 309S stainless steel rod grinding rod bright rod manufacturers support processing

The main differences between ground stainless steel rod and polished rod lie in the processing technology,

surface treatment, application scenarios, and price.

Processing Technology and Surface Treatment:

Ground rod: Mechanically ground, it achieves a smoother surface and precise tolerances,

making it suitable for applications with high dimensional and geometric tolerance requirements.

During the grinding process, the surface of the ground rod is ground to remove the oxide scale,

achieving a higher finish and precision.

Purpose-polished rod: Typically produced through cold drawing, fine grinding, or polishing,

it has a brighter surface and is suitable for applications requiring a smooth surface but less stringent dimensional and geometric tolerance requirements.

The surface treatment of polished rod primarily increases the surface gloss through chemical methods,

without mechanical grinding.

Applications:

Ground rod: Primarily used in applications requiring high-precision machining,

such as precision machinery and instrumentation, as it offers higher dimensional and geometric tolerance accuracy.

Pure-polished rod: Suitable for applications requiring a high surface finish, such as household goods,

automotive parts, and medical devices, due to its excellent corrosion and heat resistance.

Price: Because ground rods require more complex processing and require higher precision and surface finish,

they are generally more expensive than polished rods.

In summary, the main differences between stainless steel ground rods and polished rods lie in their processing,

surface finish, application scenarios, and price. Choosing which rod material to use depends on specific application requirements and budget considerations.

Send Inquiry to This Supplier

You May Also Like

-

Duplex Stainless Steel Rods, 2205 and 2507 Stainless Steel Round Bars, and Mechanical Spare PartsNegotiableMOQ: 100 Kilograms

-

310S Stainless Steel Bar, 2205 2507 Round Steel for Industrial Construction, Brushed FinishNegotiableMOQ: 100 Kilograms

-

C4 Nitric Acid Resistant Stainless Steel Round Steel/light Bar/forging 00Cr14Ni14Si4NegotiableMOQ: 1 Ton

-

00cr14ni14si4 Nitric Acid Resistant c4 Round Stainless Steel Bar Can Be CustomizedNegotiableMOQ: 1 Ton

-

Nitric Acid Resistant Steel 00cr14ni14si4 Austenitic Stainless Steel Bar c4 SteelNegotiableMOQ: 1 Ton

-

1.4418 Stainless Steel Rod 165M Light Circle SS2387 Round Rod 0cr16ni5Mo Round SteelNegotiableMOQ: 1 Ton

-

S32900 Super Stainless Steel Bar 1.4460 329 Stainless Steel Round Bar Can be CustomizedNegotiableMOQ: 1 Ton

-

Hot Rolled 15-5PH Solid Bar Black Bar High Precision Stainless Steel Bar Smooth RoundNegotiableMOQ: 1 Ton

-

ASTM 304 316 Bright High Strength Stainless Steel Rod PriceNegotiableMOQ: 1 Ton

-

Stainless Steel Round Bar ASTM AISI 316 304 Stainless Steel Bar Hot Rolled Ss Rod for SaleNegotiableMOQ: 1 Ton