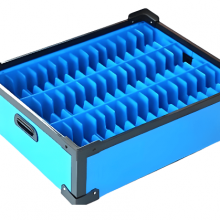

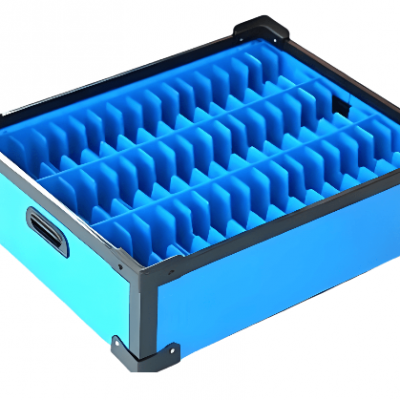

Corrugated Plastic Dividers and Inserts for Automotive Parts Packaging

Corrugated plastic dividers and inserts are lightweight, durable, and moisture-resistant solutions designed to separate and protect items during storage or transport. Made from high-impact polypropylene (PP) hollow sheets, they are widely used in returnable packaging systems across industries such as automotive, electronics, agriculture, and logistics. These dividers are fully customizable in size, shape, and slot configuration to suit different box types and product dimensions. They help reduce damage, improve packing efficiency, and support sustainable, reusable packaging operations.

Product Data:

Product Options:

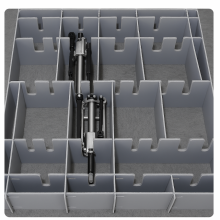

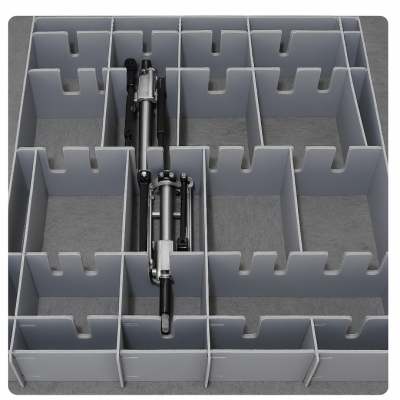

· Box Compatibility: Designed for totes, crates, cartons, or custom containers

· Insert Type: Fixed grid, adjustable dividers, layer pads, edge protectors

· Reinforcement Options: Edge sealing, corner protection, bottom padding

· Printing Options: Custom logos, QR codes, part numbers

· Reusability Features: Foldable, washable, chemical- and moisture-resistant

· Assembly Method: Slotted, hot-welded, ultrasonic welding, hook & loop fastening

Production Factory:At Shichuang Company, our production factory is at the heart of our operations. Equipped with cutting-edge machinery and innovative processes, we ensure the highest standards of quality and efficiency. Our commitment to excellence drives our production, enabling us to deliver superior corrugated plastic products to clients worldwide, including Australia (Sydney, Melbourne, Brisbane, Adelaide, Perth, Hobart, Canberra, Darwin), the USA, the UK, and New Zealand.

Our production facility is designed to optimise workflow and productivity. Each stage of the manufacturing process is meticulously planned and executed to maximise efficiency and minimise waste. From the initial material selection to the final inspection, every step is carried out with precision and care. Our team of skilled technicians and engineers work tirelessly to ensure that every product meets our rigorous quality standards.

Our production factory boasts state-of-the-art machinery and equipment, allowing us to produce a wide range of high-quality corrugated plastic products. From advanced extrusion lines to precision cutting machines, our investment in technology ensures efficiency and product excellence.

Our equipment includes:

Extrusion Lines: Advanced extrusion technology for consistent quality.

Cutting Machines: Precision cutting for accurate dimensions and shapes.

Lamination Machines: High-quality lamination for added strength and durability.

Printing Machines: Custom printing capabilities for branding and labelling.

Send Inquiry to This Supplier

You May Also Like

-

Polypropylene Corrugated Knife Card – ESD Safe Electronic PackagingNegotiableMOQ: 2000 Pieces

-

Eco-Friendly PP Corrugated Pill & Medicine Boxes – Secure and DurableNegotiableMOQ: 2000 Pieces

-

Polypropylene Corrugated Partition Containers – Durable ESD Safe Electronic PackagingNegotiableMOQ: 2000 Pieces

-

Polypropylene Corrugated Divider Containers – Durable ESD Protection for ElectronicsNegotiableMOQ: 2000 Pieces

-

Custom Polypropylene Knife Cards – Anti-Static Corrugated Inserts for PCBsNegotiableMOQ: 2000 Pieces

-

PP Corrugated Partition Boards – ESD Protective Packaging for ElectronicsNegotiableMOQ: 2000 Pieces

-

Customized PP Hollow Sheet Foldable Gift Box – Durable, Waterproof, Eco-FriendlyNegotiableMOQ: 2000 Pieces

-

Customizable PP Corrugated Gift Box – Foldable, Waterproof, Promotional PackagingNegotiableMOQ: 2000 Pieces

-

Customizable Green PP Hollow Sheet Skeleton Box – Waterproof, Recyclable StorageNegotiableMOQ: 2000 Pieces

-

PP Corrugated Plastic Sheets – Hollow Boards for Packing & Storage SolutionsNegotiableMOQ: 2000 Pieces