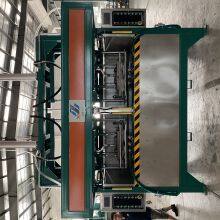

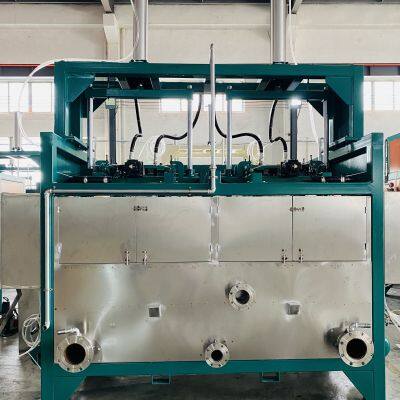

Automatic Double-cylinder Double-station Forming Machine

An Automatic Double-Cylinder Double-Station Forming Machine is a specialized molded pulp production equipment primarily used in the industrial packaging field. It efficiently manufactures various molded pulp products, such as inner trays for electronic products, coffee cup trays, and other eco-friendly packaging solutions.

Key FeaturesDual-Station Design – Equipped with two independent stations, enabling simultaneous production of products with different shapes and thicknesses in a single cycle.

PLC & Touch-Screen Control – Allows precise adjustment of production speed, vacuum adsorption time, and drying parameters to meet different product requirements.

High Efficiency & Automation – Uses a servo motor and screw guide rail system to transfer semi-finished products automatically, reducing manual labor and improving productivity.

Precision Molding – Ensures consistent product thickness and dry-wet balance through controlled vacuum adsorption and mold transfer.

Industrial Packaging – Produces protective inner trays for electronics, appliances, and fragile items.

Food & Beverage Packaging – Manufactures coffee cup trays, egg cartons, and disposable tableware.

Eco-Friendly Solutions – Supports sustainable production using recycled pulp materials.

Site Preparation – Ensure a level and stable foundation with proper power and compressed air supply.

Mechanical Assembly – Install the dual-station molding system, servo-driven transfer mechanism, and vacuum system.

Electrical & Control Setup – Connect the PLC, touch-screen interface, and sensors for automated operation.

Testing & Calibration – Run trial productions to adjust vacuum time, mold alignment, and transfer speed for optimal performance.

This machine is a high-efficiency, reliable solution in the pulp molding industry, widely adopted for its automation capabilities and versatility in producing eco-friendly packaging.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Food Box Forming MachineUS$ 1 - 5,001MOQ: 1 Set

-

25kg Bag Palletizing Machine Automatic Palletizer MachineUS$ 1 - 48000MOQ: 1 Set

-

Ultraclave Automatic Sterilizer Ac220-240vNegotiableMOQ: 1 Piece

-

Mixing Machine, Cook Machine, Automatic Kneading and Beating Machine, Electric Mixer(Wechat:13510231336)NegotiableMOQ: 2000 Pieces

-

Manual Style, Semi-Automatic, Full Automatic Long U Pipe Bending Machine Servo Cantilever Bending MachineNegotiableMOQ: 1 Set

-

Automatic Electronic Tensile Testing Machine With 1000KN CapacityUS$ 7000 - 30000MOQ: 1 Set

-

Machine Stretch Film Automatic Stretch FilmNegotiableMOQ: 1000 Kilograms

-

Best Selling in Africa and Southeast Asia Automatic Brick Machine Easy to Install Brick Making Machinery Block Forming MachineryUS$ 499 - 1142MOQ: 1 Set

-

Automatic Round Steamed Buns Shaper Maker Momo Steam Ban Forming Making Machine PriceNegotiableMOQ: 1 Set

-

Automatic Food Packing Machine Optimized for Snack and Confectionery Packaging ApplicationsNegotiableMOQ: 1 Acre