Hot Sale Hygienic ASTM F138 317lmn/316lvm Stainless Steel Bar Prices for Medical Used

Introduction

F51 duplex steel has excellent corrosion resistance, increased resistance to chloride attack and good resistance to stress corrosion cracking. F51 tensile and yield strength is higher than conventional austenitic or ferritic grades of stainless steel. It has good weldability and good formability.

Duplex steels contain both ferritic and austenitic microstructures. They have a high chromium content and a moderate nickel content. They also caontain Molybdenum. F51 material is too low in nickel to produce a fully austenitic structure, thus producing the duplex microstructure (ferrite and austenite). The main advantage of duplex F51 / 1.4462 / UNS 31803 stainless steel is the combination of properties given by both the austenitic and ferritic structure (austeno-ferritic).

F51 Stainless Steel Applications

Process industry components in sulphuric acid, phosphoric acid, ethylene oxide, polypropylene & PVC production

Equipment handling organic & fatty acids, chemical storage, tankers, heat exchangers

Marine industry and shipbuilding propellers, shafts, rudders, shaft seals, pumps, bolts, fasteners, valves, instrumentation

Oil and chemical tankers

Oil & Gas industry pumps, valves, pipe, vessels, wellhead equipment, subsea equipment, separators, heat exchangers

Pollution control systems, effluent scrubbing, flue gas desulphurisation (FGD)

Waste water treatment, sour water purification

Pulp & paper industry applications such as pulp liquor heaters, bleach tower linings, digesters, brownstock washers

Food industry applications including brewery piping, evaporators, hot liquor tanks, presses

F51 Stainless Steel Standards

▪ ASTM A182 F51 / F60

▪ ASTM A276 F51 / F60

▪ ASTM A479 F51

▪ AISI F51

▪ BS 318S13 (Wrought)

▪ BS 332C15 (Cast)

▪ WS 1.4462

▪ WS 1.4470

▪ X2CrNiMoN22.5.3

▪ AFNOR Z2CND22.05Az

▪ UNS S31803

▪ UNS S32205

▪ SAF2205 - SANMAC (Brand name)

▪ URANUS 45N (Brand name)

▪ FALC223 (Brand name)

F51 Stainless Steel Chemical Composition

| Weight% | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| Duplex F51 | 0.03 max | 2.0 max | 0.03 max | 0.02 max | 1 max | 21-23 | 4.5-6.5 | 2.5-3.5 | 0.80-0.20 |

| Alloy | Tensile Strength N/mm² | Proof Strength 0.2% N/mm² | Elongation (%) | Hardness Brinell |

| F51 | 105 | 55 | 35 | 170-255 |

| F51 | 95 | 50 | 35 | 170-255 |

| F51 stainless steel pipe sizes and specifications | |

| Grade | F51 |

| Specification | EN, DIN, JIS, ASTM, BS, ASME, AISI, ISO |

| Standard | ASTM A276/ASME SA276, ASTM A479/ASME SA479 & ASTM A164/ASME SA164 . |

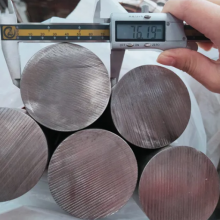

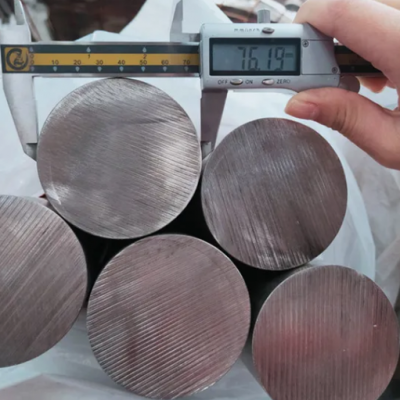

| Stainless steel round Bar | Diameter: 2mm - 600mm |

| Stainless steel bright Bar | Diameter: 2mm - 600mm |

| Stainless steel hex Bar | Dimension: 6mm - 80mm |

| Stainless steel square bar | Dimension: 3.0 - 180mm |

| Stainless steel flat bar | Thickness: 0.5mm - 200mm, Width: 1.5mm - 250 mm |

| Stainless steel angle bar | as requirements |

| Length | Normally 6m, or produce as requirements |

| Surface | Black, Bright. Peeled and Polished, Solution annealed. |

| Delivery condition | cold drawn, hot rolled, forged, grinding, centerless grinding |

| Tolerance | H8, H9, H10, H11, H12, H13,K9, K10, K11, K12 or as per clients' requirements |

Company Profile

Our Advantages

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building construction |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Send Inquiry to This Supplier

You May Also Like

-

AISI304 AISI 340L 17-4 pH AISI 431 316L Ss 202 AISI 440c Stainless Steel Round Bar Price Per KgUS$ 1650 - 2650MOQ: 1 Ton

-

China Factory Sell Directly SUS 402 1.4302 ASTM A276 S31803 316 Stainless Steel Round Bar Price Per KgUS$ 1650 - 2650MOQ: 1 Ton

-

Cold Drawn/Hot Rolled ASTM AISI JIS 201 202 2205 304 316L 310S HSS Stainless Steel Bright Solid Rod Round/Square/Angle/Flat/Channe BarUS$ 1650 - 2650MOQ: 1 Ton

-

Best Quality SUS 201/202/304/316 Stainless Steel Round Bar Flat BarUS$ 1650 - 2650MOQ: 1 Ton

-

Stainless Steel Bar Round Square Hexagonal Bar ASTM 201 202 304 316 316L 317L 310S 2205 2507 Hot/Cold Rolled Stainless Steel BarUS$ 1650 - 2650MOQ: 1 Ton

-

410 High Quality Stainless Steel Round Bar in Architectural DecorationUS$ 1650 - 2650MOQ: 1 Ton

-

China Factory Specializes C42500 C43000 C43400 Copper BarUS$ 1650 - 2650MOQ: 1 Ton

-

Hot Sale C44500 C46400 C46500 Copper Round Steel BarUS$ 1650 - 2650MOQ: 1 Ton

-

1/2" Cold Drawn 304 Stainless Steel Round BarUS$ 1650 - 2650MOQ: 1 Ton

-

3/16" Cold Drawn 420 Stainless Steel Round BarUS$ 1650 - 2650MOQ: 1 Ton