Premium Stainless Steel Round Rods - Solid Steel for Industrial Use

| Introduction INCOLOY alloys belong to the category of super-austenitic stainless steel alloys. Nickel, chromium and iron are the principal constituents of this alloy. By adding different additives this alloy can be made to resist different chemical reagents. Good strength and resistance to corrosion are characteristics of these alloys. Additives such as molybdenum and nitrogen are added to the alloy in order to increase its resistance to pitting, crevice corrosion and thermal stability. The nickel and chromium content extend the corrosion resistance of this alloy over a wide range of environments like non-oxidizing acids, aqueous, caustic chlorides, halides and pulp-mill bleaches. This alloy is available in the form of bars, billets, sheets, round, plate, strips and wire. This datasheet will look into the chemical composition, properties and applications of INCOLOY 25-6MO. Chemical Composition The chemical composition of INCOLOY alloy 25-6MO is given in the following table.ElementContent (%)Iron, Fe47.3Nickel, Ni24-26Chromium, Cr19-21Molybdenum, Mo6-7Manganese, Mn≤2OthersRemainderPhysical Properties The following table discusses the physical properties of INCOLOY alloy 25-6MO.PropertiesMetricImperialDensity8.03 gm/cm30.290 lb/in3Mechanical Properties The mechanical properties of INCOLOY alloy 25-6MO are tabulated below.PropertiesMetricImperialTensile strength(annealed)689 MPa100 ksiYield strength(annealed)331 MPa48 ksiElongation at Break( in 2 in 50 mm)≥42%≥42%Hardness, Rockwell B8686Modulus of Elasticity188 GPa27300 ksiPoissons Ratio0.330.33Other Designations Some of the designations used to denote INCOLOY alloy 25-6MO are listed below:- UNS N08926 Fabrication Machinability Machining characteristics of this INCOLOY alloy 25-6MO is similar to that of other austenitic alloys. Machining of INCOLOY alloy 25-6MO should be done at a slightly lower speed when compared stainless steel using rigid tooling and optimum lubrication and cooling. Welding INCOLOY alloy 25-6MO can be welded by gas metal arc welding, gas tungsten arc welding, shielded arc welding, plasma arc welding and submerged metal arc welding. The filler metal and electrodes are usually made of INCONEL alloy. Hot working INCOLOY alloy 25-6MO can be hot worked at temperature ranges of 980-1150°C (1800-2100°F). Cold Working Cold rolling may be done on the alloy after annealing. Annealing INCOLOY alloy 25-6MO should be annealed at temperatures greater than 1175°C (2150°F). Applications The INCOLOY alloy 25-6MO is used in the following applications: Chemical and food processing Paper bleaching plants Marine and offshore platform equipment Air pollution control systems Salt plant evaporators Condenser tubes, service water pipes and feed water heaters. |

With an unwavering commitment to excellence, we proudly adhere to the ISO9001:2000 quality management system and possess various production licenses that affirm our high standards. Our dedication to maintaining the utmost quality ensures that every product leaving our facility meets and exceeds rigorous quality benchmarks.

Please note: We offer the capability to produce non-standard stainless steel rods, custom-tailored from a variety of materials and specifications. This ensures flexibility and precision to meet unique requirements. Whatever your specific needs, we are fully equipped to deliver products perfectly aligned with your specifications and standards.

Detailed Overview: Materials, Application Scope, and Quality Management of Stainless Steel Rods.

Material Selection: Our range includes premium grades such as 304, 304L, 321, 316, 316L, 310S, and 630, guaranteeing top-notch performance in every application. Each material is chosen for its exceptional properties, ensuring superior durability and reliable performance.

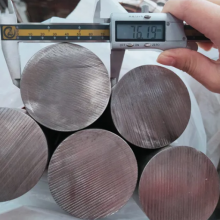

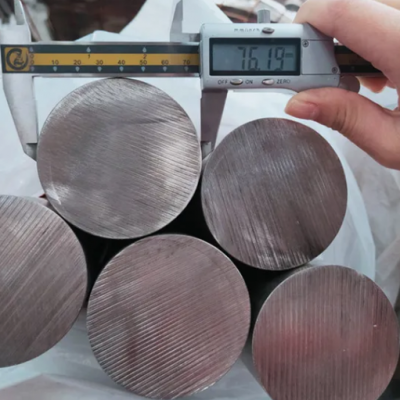

Our extensive range of materials includes 201, 202, 301, 304, 303, 316, 316L, 304L, 321, 2520, 1Cr13, 2Cr13, 3Cr13, duplex steel, antibacterial steel, and more. Specifications are identified by diameter (e.g., '50' denotes a 50 mm diameter round steel). Our offerings include hot-rolled, forged, and cold-drawn forms, with hot-rolled sizes spanning from 5.5 mm to 250 mm. This versatility allows us to efficiently meet a broad spectrum of industrial project requirements.

Our stainless steel rods find applications across a diverse array of industries including petroleum, electronics, chemical, pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military, and more. This extensive range of applications underscores the unparalleled versatility and essential nature of our products.

Quality management is our utmost priority, reinforced by our ISO9001:2000 quality management system certification and a host of production licenses, ensuring the highest standards. Our stringent quality control processes guarantee unmatched reliability and performance in every product we deliver.

| Chemical Composition (%) | ||||||||

| Grade | C | Mn | Si | Cr | Ni | P | S | |

| 201 | ≤0.15 | 5.5-7.5 | ≤0.75 | 16.0-18.0 | 3.5-5.5 | ≤0.06 | ≤ 0.03 | |

| 304 | ≤0.08 | ≤2.0 | ≤1.0 | 18.0-20.0 | 8.0-10.5 | ≤0.045 | ≤ 0.03 | |

| 304L | ≤0.03 | ≤2.0 | ≤1.0 | 18.0-20.0 | 9.0-13.0 | ≤0.045 | ≤ 0.03 | |

| 304H | 0.04-0.10 | ≤2.0 | ≤0.75 | 18.0-20.0 | 8.0-10.5 | ≤0.045 | ≤ 0.03 | |

| 304N | ≤0.08 | ≤2.0 | ≤0.75 | 18.0-20.0 | 8.0-10.5 | ≤0.045 | ≤ 0.03 | |

| 305 | ≤0.12 | ≤2.0 | ≤0.75 | 17.0-19.0 | 10.5-13.0 | ≤0.045 | ≤ 0.03 | |

| 309 | ≤0.20 | ≤2.0 | ≤0.75 | 22.0-24.0 | 12.0-15.0 | ≤0.045 | ≤ 0.03 | |

| 309S | ≤0.08 | ≤2.0 | ≤0.75 | 22.0-24.0 | 12.0-15.0 | ≤0.045 | ≤ 0.03 | |

| 310S | ≤0.08 | ≤2.0 | ≤1.5 | 24.0-26.0 | 19.0-22.0 | ≤0.045 | ≤ 0.03 | |

| 314 | ≤0.25 | ≤2.0 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | ≤0.045 | ≤ 0.03 | |

| 316 | ≤0.08 | ≤2.0 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | ≤0.045 | ≤ 0.03 | Mo: 2.0-3.0 |

| 316L | ≤0.03 | ≤2.0 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | ≤0.045 | ≤ 0.03 | Mo: 2.0-3.0 |

| 316N | ≤0.08 | ≤2.0 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | ≤0.045 | ≤ 0.03 | Mo: 2.0-3.0 |

| 316Ti | ≤0.08 | ≤2.0 | ≤1.0 | 16.0-18.0 | 10.0-14.0 | ≤0.045 | ≤ 0.03 | Mo: 2.0-3.0 Ti: 0.2-0.7 |

| 317L | ≤0.03 | ≤2.0 | ≤0.75 | 18.0-20.0 | 11.0-15.0 | ≤0.045 | ≤ 0.03 | |

| 321 | ≤0.08 | ≤2.0 | ≤0.75 | 17.0-19.0 | 9.0-12.0 | ≤0.045 | ≤ 0.03 | |

| 321H | 0.04-0.10 | ≤2.0 | ≤0.75 | 17.0-19.0 | 9.0-12.0 | ≤0.045 | ≤ 0.03 | |

| 329 | ≤0.08 | ≤1.00 | ≤0.75 | 23.0-28.0 | 2.0-5.0 | ≤0.04 | ≤0.03 | |

| 347H | 0.4-0.10 | ≤2.0 | ≤0.75 | 17.0-19.0 | 9.0-13.0 | ≤0.045 | ≤ 0.03 | |

| 409 | ≤0.08 | ≤1.0 | ≤1.0 | 10.5-11.75 | 0.50 | ≤0.045 | ≤ 0.03 | |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | 11.5-13.5 | 0.75 | ≤0.04 | ≤0.03 | |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | 16.0-18.0 | 0.75 | ≤0.04 | ≤0.03 | |

| 17-4PH | ≤0.07 | ≤1.0 | ≤1.0 | 15.5-17.5 | 3.0-5.0 | ≤0.04 | ≤0.03 | |

| 17-7PH | ≤0.09 | ≤1.0 | ≤1.0 | 16.0-18.0 | 6.5-7.75 | ≤0.04 | ≤0.03 | |

| 904L | ≤0.02 | ≤2.0 | ≤1.0 | 19.0-23.0 | 23.0-28.0 | ≤0.045 | ≤0.035 | |

| 2205 | ≤0.03 | ≤2.0 | ≤1.0 | 22.0-23.0 | 4.5-6.5 | ≤0.03 | ≤0.02 | |

| 2507 | ≤0.03 | ≤1.0 | ≤0.8 | 24.0-26.0 | 6.0-8.0 | ≤0.035 | ≤0.02 | |

With an unwavering commitment to excellence, we proudly adhere to the ISO9001:2000 quality management system and possess various production licenses that affirm our high standards. Our dedication to maintaining the utmost quality ensures that every product leaving our facility meets and exceeds rigorous quality benchmarks.

Please note: We offer the capability to produce non-standard stainless steel rods, custom-tailored from a variety of materials and specifications. This ensures flexibility and precision to meet unique requirements. Whatever your specific needs, we are fully equipped to deliver products perfectly aligned with your specifications and standards.

Detailed Overview: Materials, Application Scope, and Quality Management of Stainless Steel Rods.

Material Selection: Our range includes premium grades such as 304, 304L, 321, 316, 316L, 310S, and 630, guaranteeing top-notch performance in every application. Each material is chosen for its exceptional properties, ensuring superior durability and reliable performance.

Our extensive range of materials includes 201, 202, 301, 304, 303, 316, 316L, 304L, 321, 2520, 1Cr13, 2Cr13, 3Cr13, duplex steel, antibacterial steel, and more. Specifications are identified by diameter (e.g., '50' denotes a 50 mm diameter round steel). Our offerings include hot-rolled, forged, and cold-drawn forms, with hot-rolled sizes spanning from 5.5 mm to 250 mm. This versatility allows us to efficiently meet a broad spectrum of industrial project requirements.

Our stainless steel rods find applications across a diverse array of industries including petroleum, electronics, chemical, pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military, and more. This extensive range of applications underscores the unparalleled versatility and essential nature of our products.

Quality management is our utmost priority, reinforced by our ISO9001:2000 quality management system certification and a host of production licenses, ensuring the highest standards. Our stringent quality control processes guarantee unmatched reliability and performance in every product we deliver.

Key Features:

1. Extensive Inventory - Maintains large stock of standard and specialized steel products

2. Value-Added Services - Provides cutting, leveling, slitting, and other processing services

3. Supply Chain Expertise - Reliable logistics network for just-in-time delivery

4. Technical Support - Metallurgical expertise to help customers select optimal materials

5. Competitive Pricing - Cost-effective solutions through strategic partnerships with mills

Send Inquiry to This Supplier

You May Also Like

-

Uns S31254 ASTM A276 Welding Rod for Superior Corrosion ResistanceUS$ 35 - 41MOQ: 10 Tons

-

ASTM A479 321 Diameter 30mm Length 2000mm Hot Rolled Stainless Steel Round BarUS$ 1650 - 2650MOQ: 1 Ton

-

Durable Stainless Steel Round Bars for Industrial ApplicationsUS$ 1650 - 2650MOQ: 1 Ton

-

Bright 309 410 420 304 316L Stainless Steel Round Bar With Sepreme Hot WorkabilityUS$ 1650 - 2650MOQ: 1 Ton

-

ASTM 201/202/304/304L Metal Rod 6mm Round Stainless Steel BarUS$ 1650 - 2650MOQ: 1 Ton

-

6mm 8mm Round Stainless Steel 316 304 Stainless Steel Bar RodUS$ 1650 - 2650MOQ: 1 Ton

-

Hot Selling ASTM Stainless Steel Round RodUS$ 1650 - 2650MOQ: 1 Ton

-

China Supplier Best Price AMS 5880 440c Stainless Steel Round Bar for Making KnifeUS$ 1650 - 2650MOQ: 1 Ton

-

China Supplier Best Price 254 Smo/S31254/1.4547 Stainless Steel Round Bar Manufacture for Ballast Water SystemsUS$ 1650 - 2650MOQ: 1 Ton

-

High-Performance 2219 Aluminum Bar for Aerospace Propeller PartsUS$ 1650 - 2650MOQ: 1 Ton