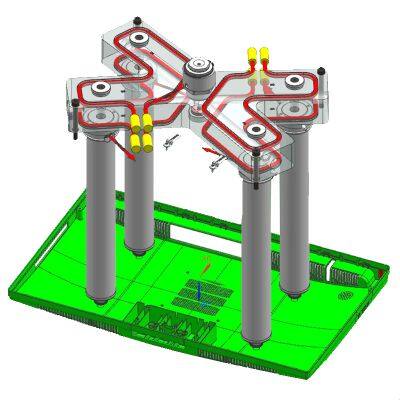

Custom Plastic Mold for TV Backplate Cover White Goods

Website: /plastic-mold-product/household-appliance

Description:

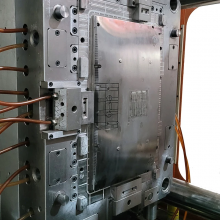

Mold Cavity |

1 Cav. |

Mold Steel |

H13 |

Part Material |

ABS |

Surface Finishing |

VDI Texture |

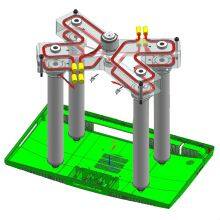

Gate |

Yudo Hot Nozzle* 4 Points |

Mold Size & Weight |

750*1050*680 mm; 3200kgs |

Mold Life |

One Million Shots |

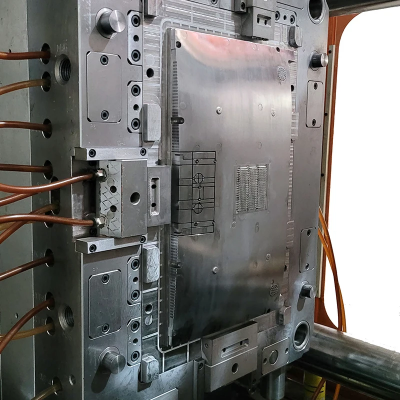

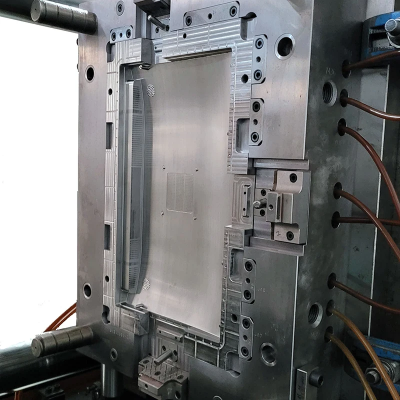

Multiple reinforcing ribs, undercut and complicated design

This TV injection mold is meticulously engineered with an array of reinforcing ribs and undercuts, ensuring the final product is not only robust and durable but also intricately designed. The strategic placement of these ribs enhances the structural integrity, preventing warping or deformation during the injection molding process. The complex design of the mold allows for a seamless and aesthetically pleasing exterior, while the reinforced structure guarantees longevity and resistance to impact. This innovative approach to mold design reflects our commitment to producing high-quality, reliable home appliance components that stand the test of time.

Mold manufacturing for TV Backplate Cover

Our cutting-edge TV casing mold, featuring an inverted design, showcases our unparalleled expertise in the home appliance mold industry. This innovative mold boasts several key advantages that set it apart. Firstly, the inverted structure enhances the coaxiality of the product, ensuring a precise fit for the casing and reducing assembly errors, thereby improving overall product quality. Secondly, the design simplifies maintenance, cutting down on repair costs and boosting production efficiency. Moreover, the unique inverted mold allows for smoother demolding, minimizing the risk of surface scratches and ensuring the aesthetic and durability of the TV casing

Send Inquiry to This Supplier

You May Also Like

-

Custom Overmolding/2k Plastic Injection Mold Two-Shot Plastic MoldNegotiableMOQ: 1 Unit

-

PET Multi Cavity Custom Plastic Injection MoldNegotiableMOQ: 1 Unit

-

Multi Cavity Custom Plastic Injection Mold for Switch Socket PlugNegotiableMOQ: 1 Unit

-

Custom Plastic Injection Mold for Automotive Drawer-Automotive Interior TrimNegotiableMOQ: 1 Unit

-

Custom Plastic Injection Mold for Automotive Hot Runner SystemNegotiableMOQ: 1 Unit

-

Custom Plastic Mold 1+1 Cavity Family Mold for Automotive Door Switch PanelNegotiableMOQ: 1 Unit

-

Custom Plastic Injection Mold for Automotive Lighting Multi Cavity MouldNegotiableMOQ: 1 Unit

-

Custom Plastic Injection Mold for Automotive Rearview Housing Family Mold 1+1 Multi CavityNegotiableMOQ: 1 Unit

-

Custom Plastic Injection Mold for Automotive Windscreen WipersNegotiableMOQ: 1 Unit

-

Custom Plastic Mold for Automotive Control PanelNegotiableMOQ: 1 Unit