Website: /plastic-mold-product/electronic

Description:

Mold Cavity | 1 Cav. |

Mold Steel | S136H |

Surface Finishing | VDI Texture + Polishing |

Gate | Cold runner, side gate |

Injection Machine | 260T |

Mold Size & Weight | 450*522*471 mm; 600kgs |

Mold Life | 300,000 shots |

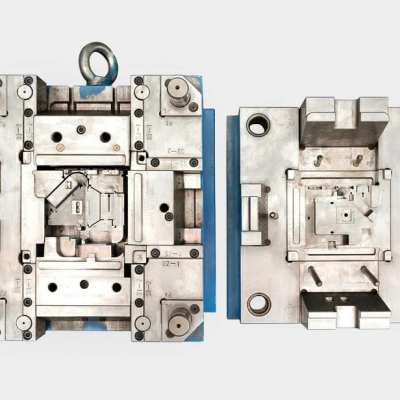

Slider Mechanism

The plastic enclosure has a complex structure with numerous round holes, square holes, and ribs. This mold design requires the inclusion of a large slider for core pulling as well as a small slider for the same purpose. The large slider is powered by a hydraulic cylinder for core extraction, whereas the small slider operates using an angled guide pillar for core pulling.

As the mold opens, the core pulling process begins with the angled pin, which extracts the core at an angle. After the core pulling is finished, the large slider is then activated by the oil cylinder to complete the core extraction. When the mold closes, the small slider is first closed by the angled guide pin, after which the oil cylinder repositions the large slider back to its closed position.

Solution for Sticking Issue

The slider makes kiss-off with the internal angle lifter, leading to a sticking issue. To address the problem of the plastic part sticking to the slider, an ejector pin within the slider is necessary on the inner side of the part. A small spring is incorporated into the design of the slider ejector pin.

Furthermore, wear-resistant plates are designed on both the inclined surface and the base of the slider to ease the assembly of the tooling and f to allow for adjustments.

Cooling System

Beyond the cooling systems in the core and cavity areas, intricate cooling channels have been meticulously designed within the large lifter to ensure even temperature distribution during the molding process. Furthermore, a network of water channels is strategically integrated into the water sprue plate to facilitate more efficient heat dissipation. These enhancements are aimed at minimizing the risk of part deformation and significantly improving the overall efficiency of the injection molding operation.

Send Inquiry to This Supplier

You May Also Like

-

Custom Plastic Injection Mold for Marine Thruster EnclosureNegotiableMOQ: 1 Unit

-

Custom PVC Plastic Mold for Threaded Pipe Fittings Multi Cavity Injection MoldingNegotiableMOQ: 1 Unit

-

Custom Plastic Injection Mold for 3D Printer Housing-Injection Molding ServiceNegotiableMOQ: 1 Unit

-

Custom Plastic Household Mold for Coffee Pot HandlesNegotiableMOQ: 1 Yard

-

Custom Plastic Mold for Hair DryerNegotiableMOQ: 1 Unit

-

Custom Plastic Injection Mold for Router With 3CNegotiableMOQ: 1 Unit

-

Custom Plastic Injection Mold for Sweeper HousingNegotiableMOQ: 1 Unit

-

Custom Plastic Mold for TV Backplate Cover White GoodsNegotiableMOQ: 1 Unit

-

Custom Overmolding/2k Plastic Injection Mold Two-Shot Plastic MoldNegotiableMOQ: 1 Unit

-

PET Multi Cavity Custom Plastic Injection MoldNegotiableMOQ: 1 Unit