Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating Voltage

24V DC (±10%)

Dimensions

100mm×80mm×50mm

Operating Temperature

-20°C to +65°C

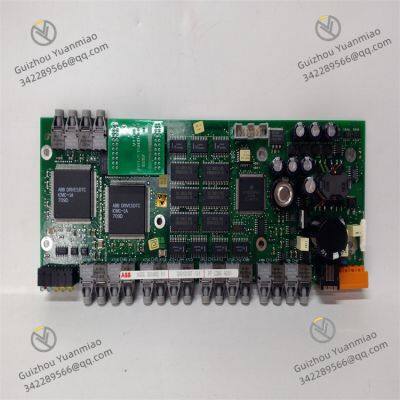

Overview

The ABB PPC380AE01 HIEE300885R0001 is a digital input module meticulously designed for industrial automation scenarios, belonging to ABB's renowned PPC380 series. With ABB's profound technical accumulation in the field of electrical and automation, this module plays a key role in industrial automation systems, aiming to provide precise and efficient digital signal acquisition and transmission services for various complex industrial processes, strongly promoting industrial production towards intelligence and efficiency.

Technical Parameters

| Parameter Category | Details |

|---|

| Product Model | PPC380AE01 HIEE300885R0001 |

| Product Type | Digital Input Module |

| Operating Voltage | DC 24V (±10%) |

| Power Consumption | Approximately 3W |

| Input Channels | 8 channels |

| Input Signal Types | Dry contacts, NPN/PNP transistor outputs |

| Input Voltage Range | Dry contacts: Open circuit voltage up to 30V DC; Closed current minimum 1mA;

NPN/PNP: Low level 0-1V DC, High level 4-30V DC |

| Isolation Method | Optoelectronic isolation |

| Isolation Voltage | 500V AC (RMS), 1 minute |

| Response Time | Typical value 5ms (configurable, range 1-20ms) |

| Sampling Frequency | Up to 1kHz |

| Communication Interface | RS485 (supports Modbus RTU protocol) |

| Communication Rate | Up to 115.2Kbps |

| Protection Level | IP20 |

| Installation Method | 35mm DIN rail installation |

| Dimensions | 100mm×80mm×50mm |

| Weight | Approximately 0.2kg |

Functional FeaturesHigh-Reliability Design

Using high-quality electronic components, combined with optimized circuit layout and manufacturing processes, and undergoing strict high-low temperature testing, vibration testing, and electromagnetic compatibility testing, it can operate stably in harsh industrial environments such as high/low temperature and strong electromagnetic interference, ensuring long-term reliable operation, effectively reducing equipment failure rates, and minimizing maintenance costs.

High-Speed Signal Processing

With high-speed signal transmission and response performance, it can quickly capture changes in digital signals from field devices. Combined with a 1kHz sampling frequency and a minimum 1ms response time, it can accurately and synchronously collect signals, greatly improving the real-time performance and accuracy of the control system to meet the needs of industrial applications requiring fast signal processing.

Diverse Signal Adaptation

Supporting multiple digital input signal types such as dry contacts and NPN/PNP transistor outputs, it can flexibly adapt to various field devices such as limit switches, proximity switches, sensors, and relays. With strong versatility, it can easily integrate into different industrial automation system architectures.

Flexible Programmable Function

Users can customize parameters such as input signal logic, filtering time, and response mode through programming software, achieving personalized configuration for specific application scenarios to meet diverse control strategy requirements and enhancing the module's application flexibility and adaptability.

Electrical Isolation Protection

Adopting optoelectronic isolation technology, it electrically isolates input signals from the control system, effectively resisting external electrical interference, preventing interference signals from penetrating into the control system to affect normal operation, protecting backend equipment from damage caused by high voltage and large current impacts, and improving system stability and safety.

Convenient Communication Interaction

Equipped with an RS485 communication interface and supporting the Modbus RTU protocol, it can conveniently communicate with other devices such as PLCs, DCS systems, and host computers, quickly and accurately transmitting collected digital signals to the control system to realize data interaction and collaborative work between devices, helping to build an efficient industrial automation network.

Application FieldsIndustrial Automation Production Lines

In automated production lines such as automobile manufacturing, electronic device production, and food & beverage processing, it is used to connect various sensors and switches to collect digital signals such as equipment operation status, material positions, and product detection results (e.g., robotic arm in-position signals, conveyor belt start/stop signals, product counting signals), providing real-time and accurate data for PLC or DCS systems to achieve automated operation and precise control of production lines, improving production efficiency and product quality.

Power System Monitoring

Applied to power facilities such as power plants and substations, it collects digital quantities such as the switching status of circuit breakers, disconnectors, and relays, and fault alarm signals, real-time monitoring the operating status of the power system. Combined with communication functions, it uploads data to the power monitoring system to assist operation and maintenance personnel in remote monitoring and fault diagnosis, ensuring the safe and stable operation of the power system.

Intelligent Building Control Systems

In intelligent buildings, it connects devices such as access control system card readers, fire alarm sensors, and lighting control switches to collect digital signals such as access control card swiping signals, fire alarm signals, and illuminance sensor signals, transmitting these digital signals to the building automation system to realize functions such as access control, fire alarm linkage, and intelligent lighting adjustment, improving the intelligent management level and safety of buildings.

Process Control Industries

In process control fields such as chemical, petroleum, and metallurgy, it collects digital signals from field instruments such as temperature switches, pressure switches, and level switches, cooperating with control systems to achieve over-limit alarms and automatic control of process parameters such as temperature, pressure, and liquid level, ensuring the stable operation of chemical production, petroleum refining, metallurgical smelting, and other technological processes, and safeguarding production safety and product quality.

Transportation Facilities Automation

Used in systems such as automatic fare collection gates, elevator control, and platform door control in rail transit stations, it collects digital quantities such as gate passage signals, elevator operation status signals, and platform door switch status signals, providing data support for the automation control systems of transportation facilities to achieve efficient operation management and safety safety assurance, and enhancing passengers' travel experience.